Correction method for large-scale scanner consisting of multiple linear array photoelectric sensor

A photoelectric sensor and correction method technology, applied in the field of image scanning, to achieve the effect of reducing production and transportation costs, reducing processing accuracy requirements, and meeting the requirements of speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The correction method of the large format scanner that the present invention is made up of a plurality of linear array photoelectric sensors comprises the following steps:

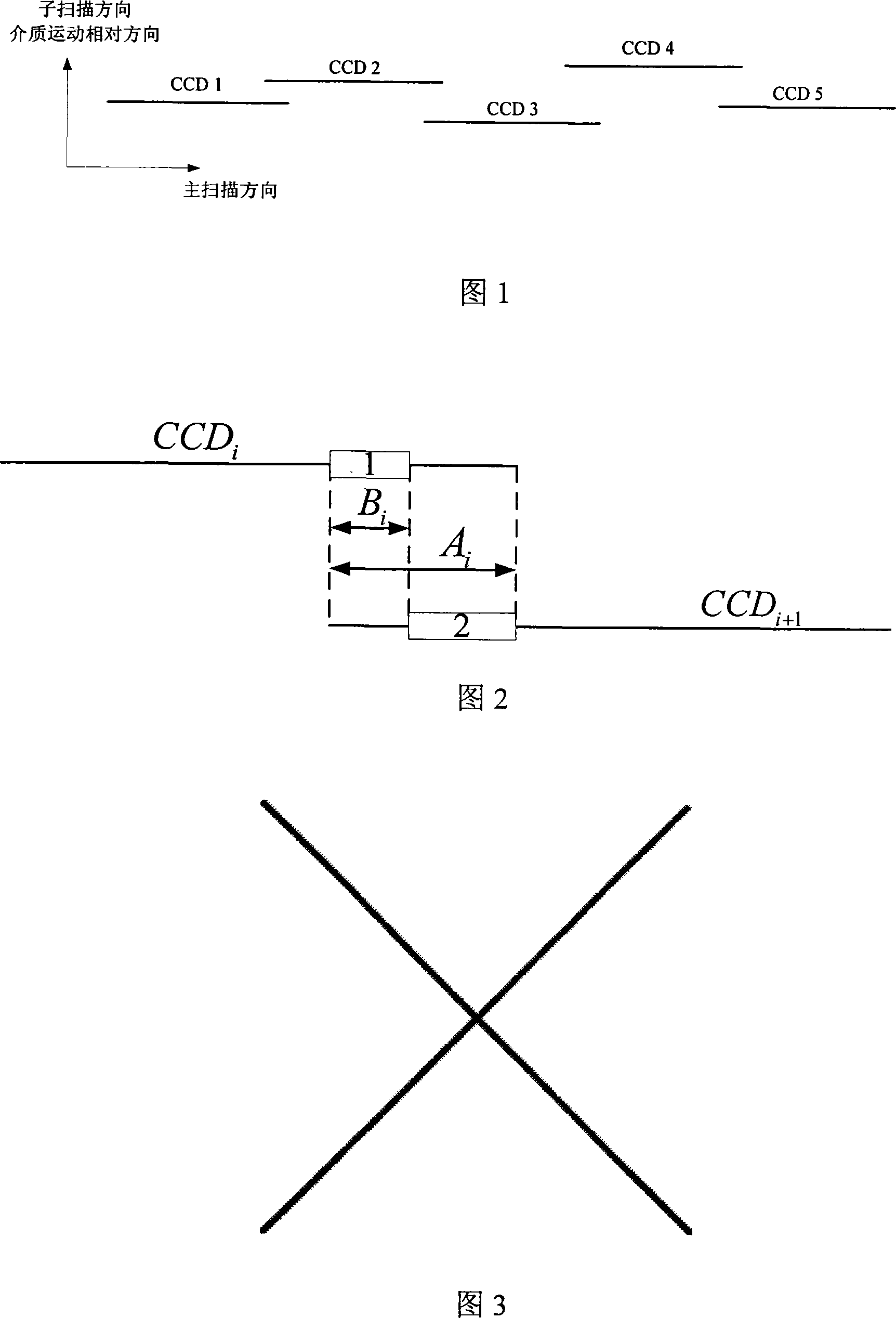

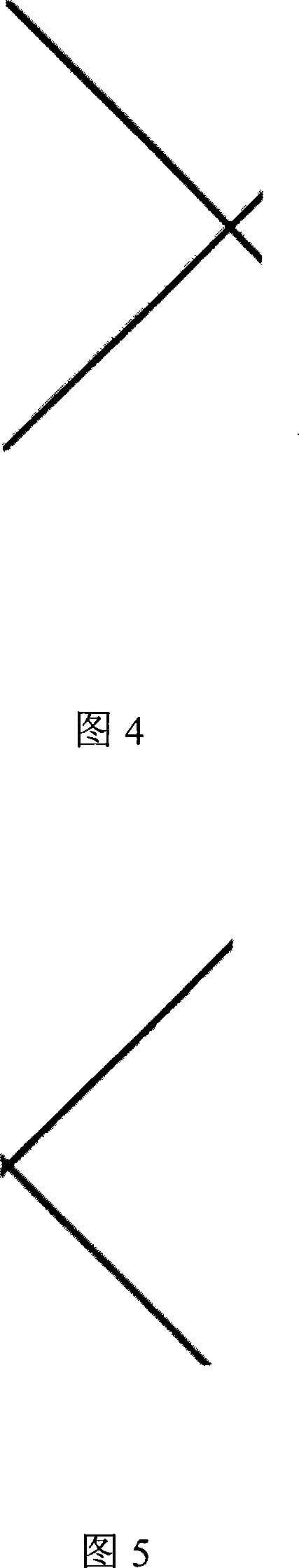

[0016] (1) Set the number of pixels received by a line array photoelectric sensor as N, and set the pixel number of the line array photoelectric sensor as 1~N, and place the calibration card shown in Figure 3 on two adjacent line array photoelectric sensors A At the seam of B and B, use linear array photoelectric sensors A and B to scan the calibration card at the same time to obtain two scanned images, as shown in Figure 4 and Figure 5.

[0017] (2) Calculate the overlapping length in the horizontal direction between two scanned images, so as to obtain the number of overlapping pixels A between two adjacent line array photoelectric sensors i , then the overlapping pixel number of the line photoelectric sensor A is (N-A i +1)~N, the overlapping pixel numbers of line array photoelectric sensor B are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap