Feeding device for bundled tube reactor

A feeding device and reactor technology, applied to chemical instruments and methods, chemical/physical processes, etc., can solve problems such as time-consuming, different reaction times, and reduced quality of reaction products, so as to achieve increased production, smooth feeding action, etc. , the effect of reducing the amount of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

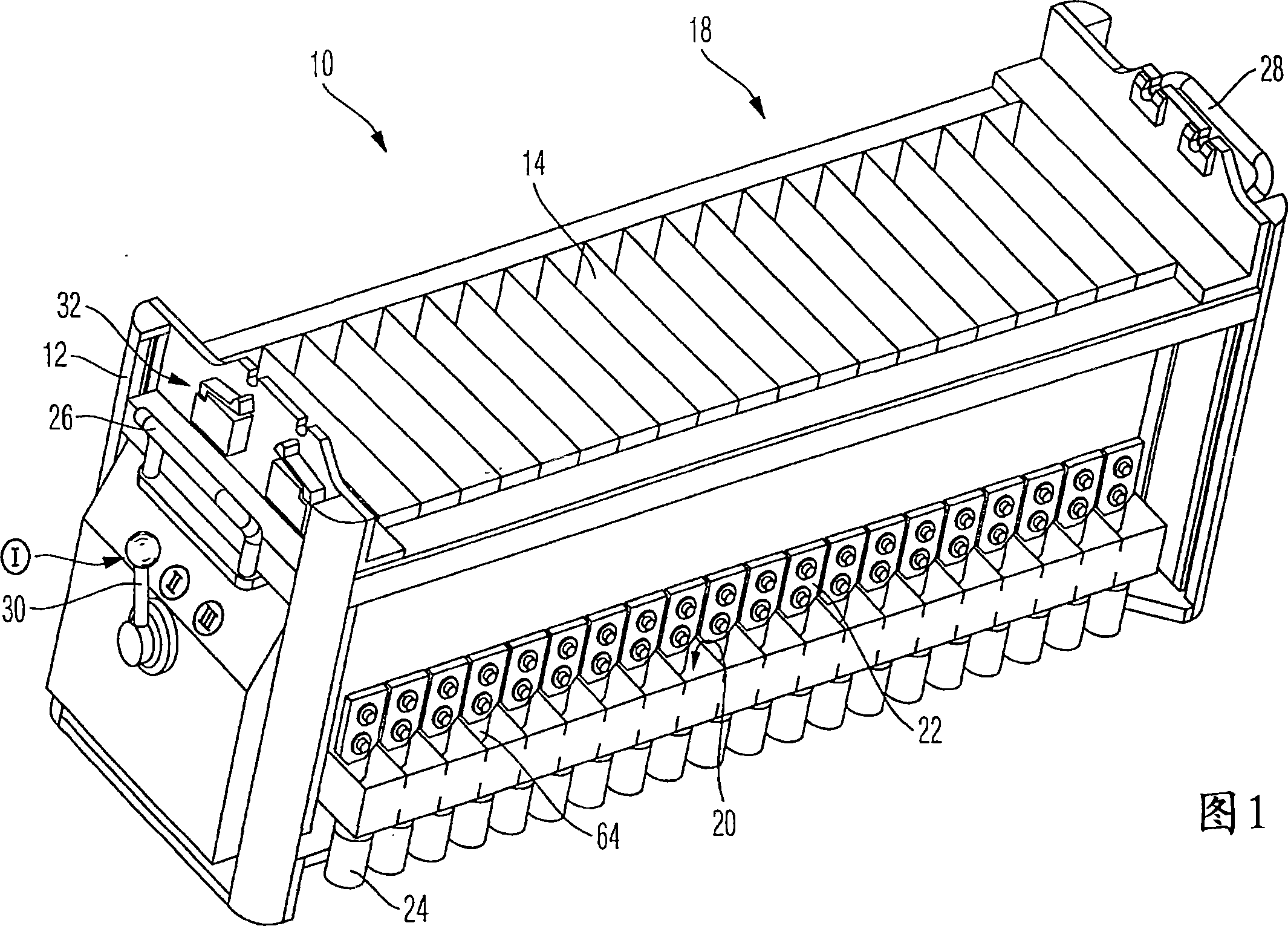

[0035] The feeding device 10 shown in FIG. 1 has a frame 12 , and the function of this frame 12 is to carry a batching box unit 18 composed of a plurality of batching boxes 14 . The discharge end of the batching box 14 is provided with downcomers 24, and these downcomers 24 stop above the tubes of the tube bundle reactor as shown in FIG. 5 . The diameter of the downcomer 24 is slightly smaller than the diameter of the tubes of the tube bundle reactor.

[0036] The width of the distribution box 14 approximately corresponds to the width of the downcomer. For example, 20 batching boxes 14 are arranged side by side. Of course, the number of batching boxes can be changed in a large range according to the needs of the feed. The discharge end of each batching box has a discharge lip 64 extending into the discharge channel 20 of the batching box like an apron. Via the support plate 22 , each discharge lip 64 is adjustably supported within the discharge channel 20 .

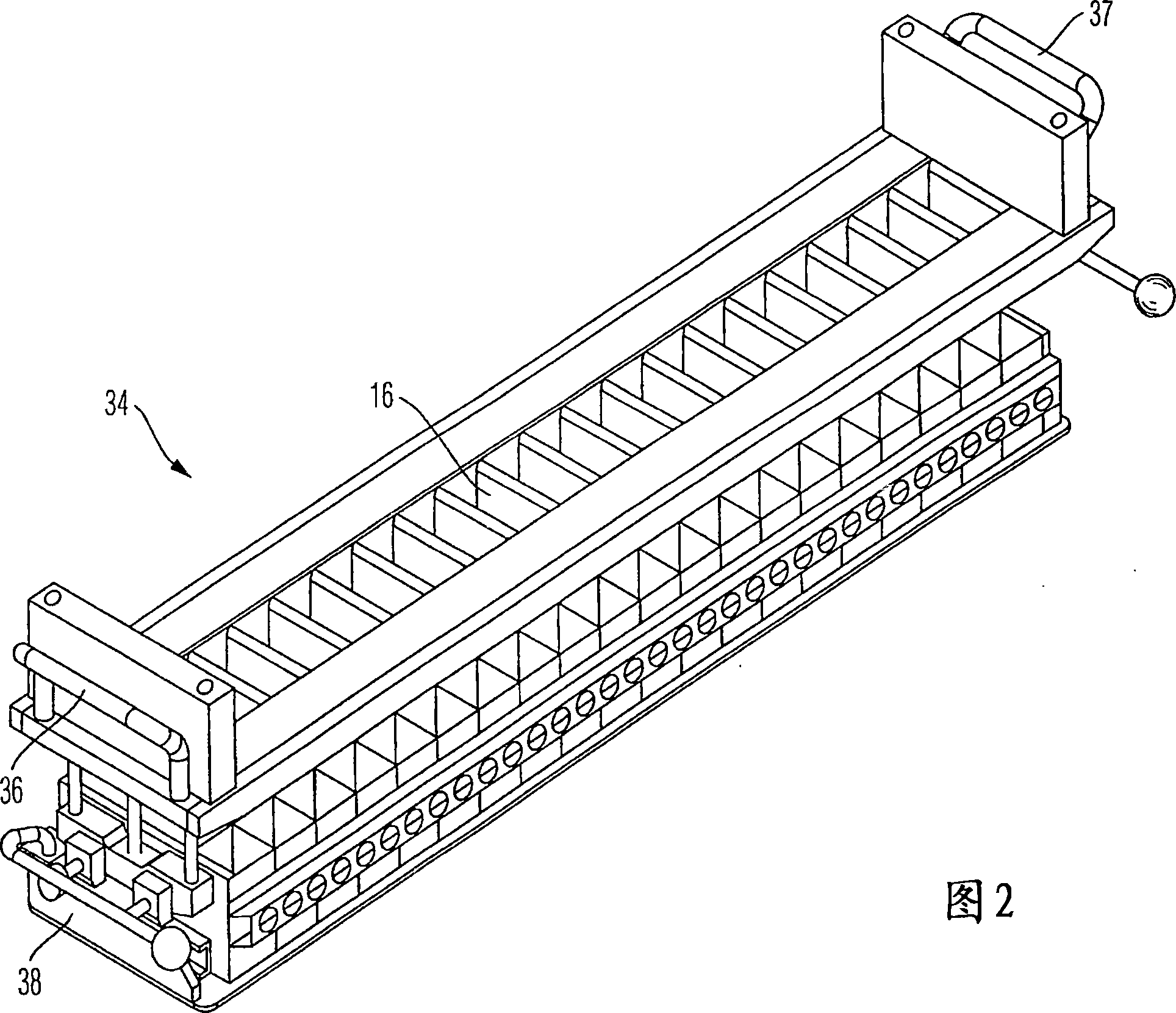

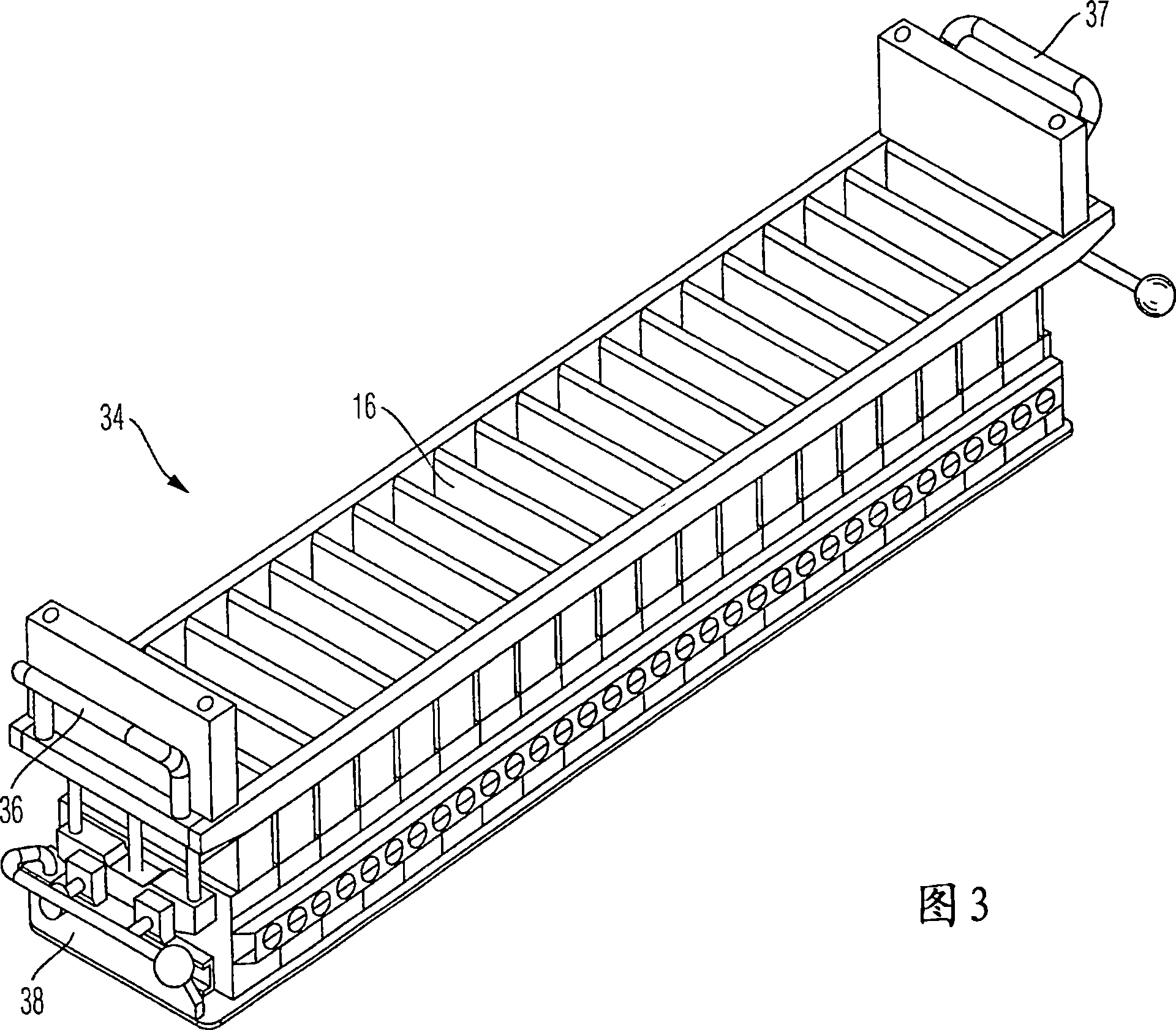

[0037] The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com