Golden silk jujube drying technology and special-purpose roasting chamber

A technology of golden silk jujube and roasting room, which is applied in application, food processing, food science and other directions, can solve the problems of reducing the quality and efficiency of jujube fruit, affecting the enthusiasm of jujube trees, and dealing with unsatisfactory quality, so as to improve the rate of commercial fruit. , The effect of low processing cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

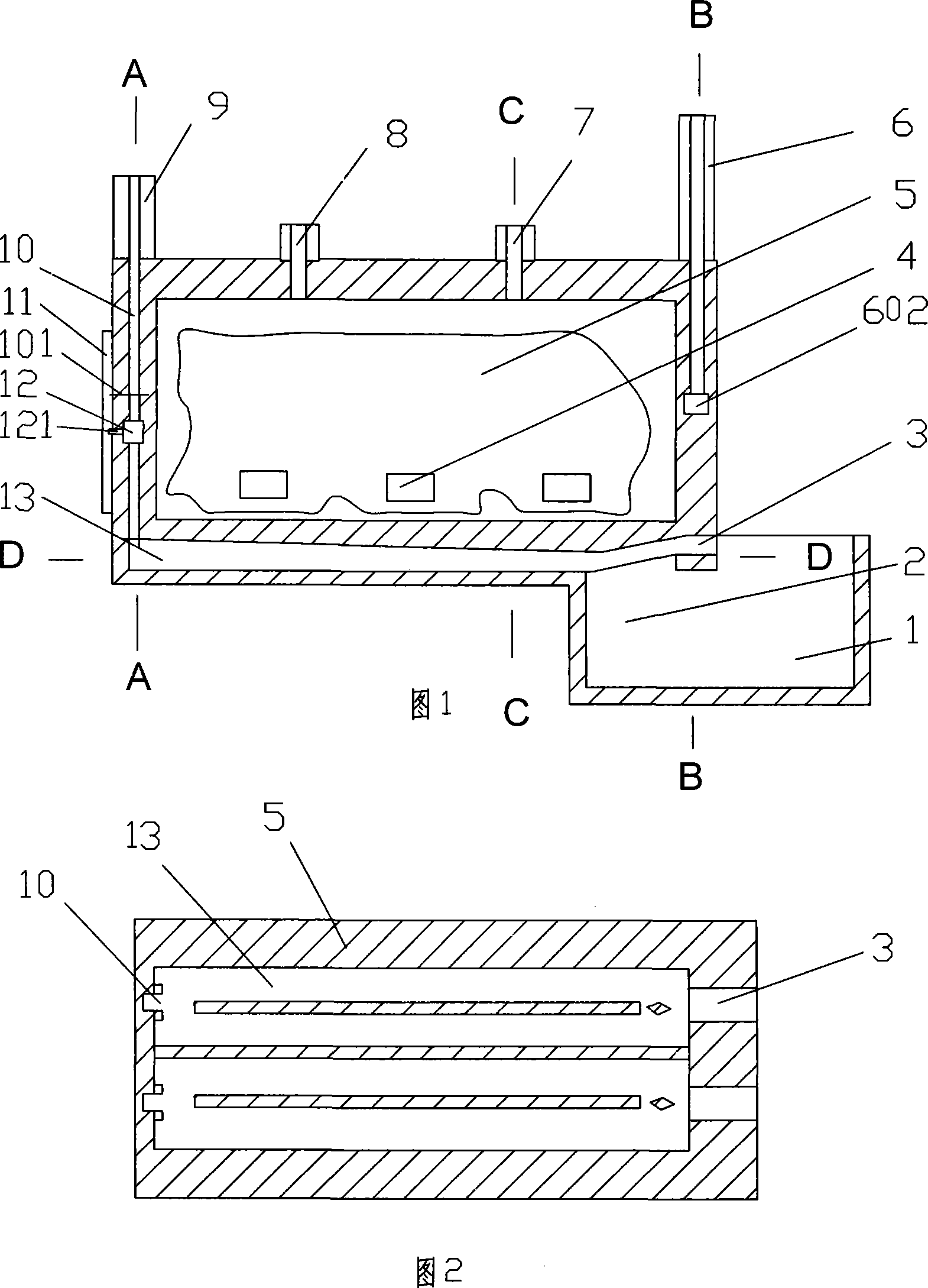

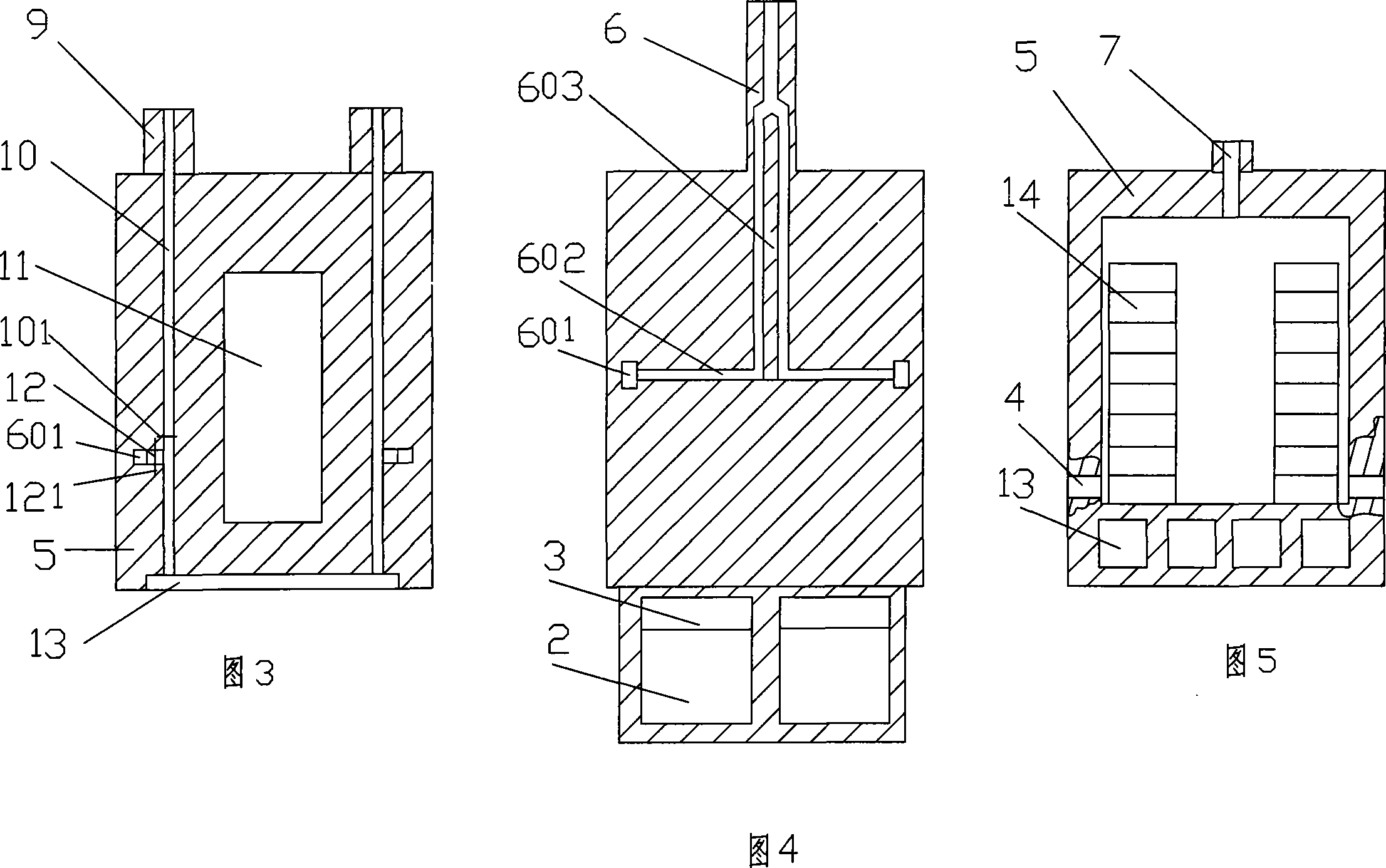

[0025] 1. The special roasting room for golden jujubes includes a room-type kiln body 5 and a kiln door 11. The top of the kiln is provided with moisture discharge holes 7 and 8, the lower part of the kiln wall is provided with an air inlet 4, and the lower part of the back wall of the kiln is provided with Furnace 3, ash pit 2, the furnace 3 communicates with the vertical flue 10 in the kiln front wall through the dark fire passage 13 under the kiln bottom, and the vertical flue 10 in the kiln front wall communicates with the chimney 9 above the kiln front wall , the large chimney 6 on the back wall of the kiln communicates with the vertical flue 603 in the back wall of the kiln, and the vertical flue 603 in the back wall of the kiln passes through the horizontal flue 602 in the back wall of the kiln and the vertical flue 603 in the two side walls of the kiln. The horizontal flue 601 is connected, and the horizontal flue 601 in the two kiln side walls is respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com