Two-section fire controller special for grain drier

A technology for grain dryers and controllers, which is applied to program control in sequence/logic controllers, electrical program control, and preservation of seeds through drying. Poor and other problems, to achieve the effect of scientific drying process, high reliability and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

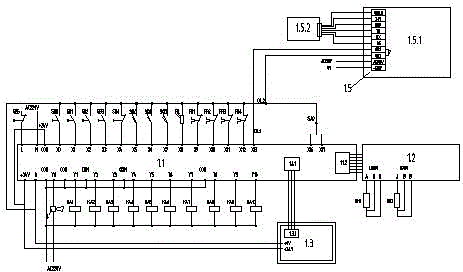

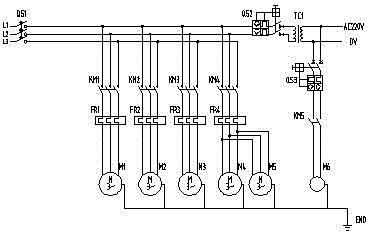

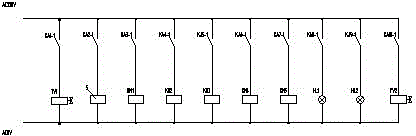

[0022] The dedicated controller for the dual-stage fire grain dryer shown in the accompanying drawing includes a programmable controller 1.1, a touch screen 1.3, a temperature sensor module 1.2 and a moisture meter 1.5; the programmable controller 1.1 is a control host with a program inside Control module; the temperature sensor module 1.2 is connected to the expansion port 1.1.2 on the right side of the programmable controller 1.1 through the flat cable on the left side; the seventeenth input port X16 of the programmable controller 1.1, the Eighteen input ports X17 are connected to the working mode switch SA0, and the first to fifth input ports X0~X4 are respectively connected to the first to fifth buttons SB0~SB4, which are mainly used to enable the programmable controller 1.1 to collect the dryer user The operation command signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com