Titanium white powder filter-press water-washing technique

A technology of titanium dioxide and filter-pressed water, applied in the directions of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of long cleaning time, easy blocking of central water holes by titanium dioxide, incomplete cleaning, etc., and achieves safe and reliable production and operation. The effect of reducing the amount of production sewage and shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

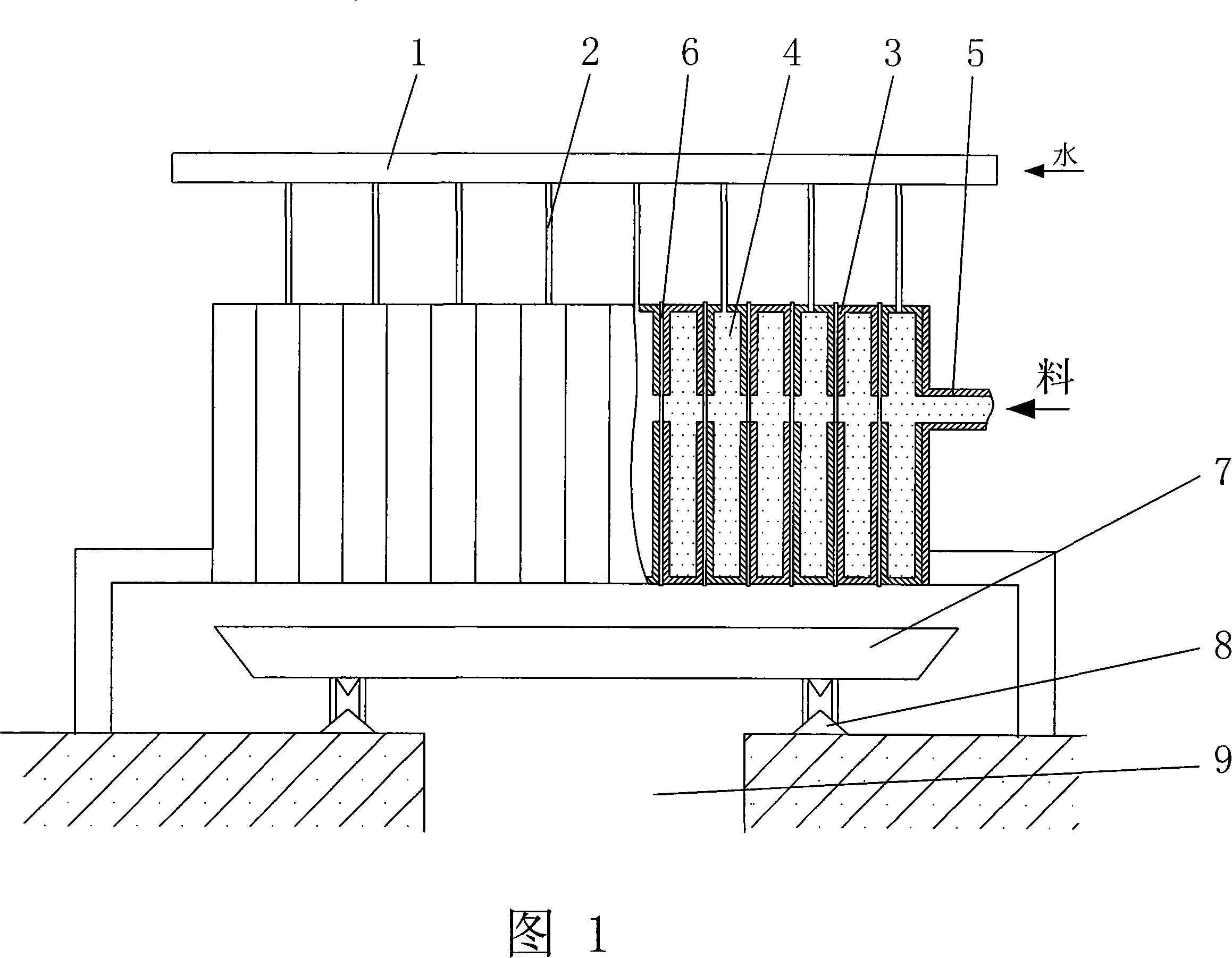

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] Referring to Fig. 1 , a titanium dioxide press filter water washing technology includes a water inlet main pipe 1 and a filter press, a titanium dioxide feed main pipe 5 enters the material cavity 4 in each filter plate 3, and clear water passes through the water inlet main pipe 1 Through the water inlet pipe 2, the water flow enters the material cavity 4 in each filter plate 3 in the filter press respectively. The volume of the material cavity is 1.81 cubic meters, and the titanium dioxide contained in each material cavity 4 is washed with water respectively. Control the water pressure of the water inlet pipe to 0.4MPa, the water flow rate is 18 tons per hour, the washing time is controlled at 40-60 minutes, and the sewage generated in each material cavity 4 passes through the filter cloth clamped between the filter plates 3 6 ooze out, flow in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com