Device for a preparatory machine for spinning

A machine controller and equipment technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of fiber parallelism damage, incorrect drawing of sliver, damage of fiber sliver, etc., to reduce costs , the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

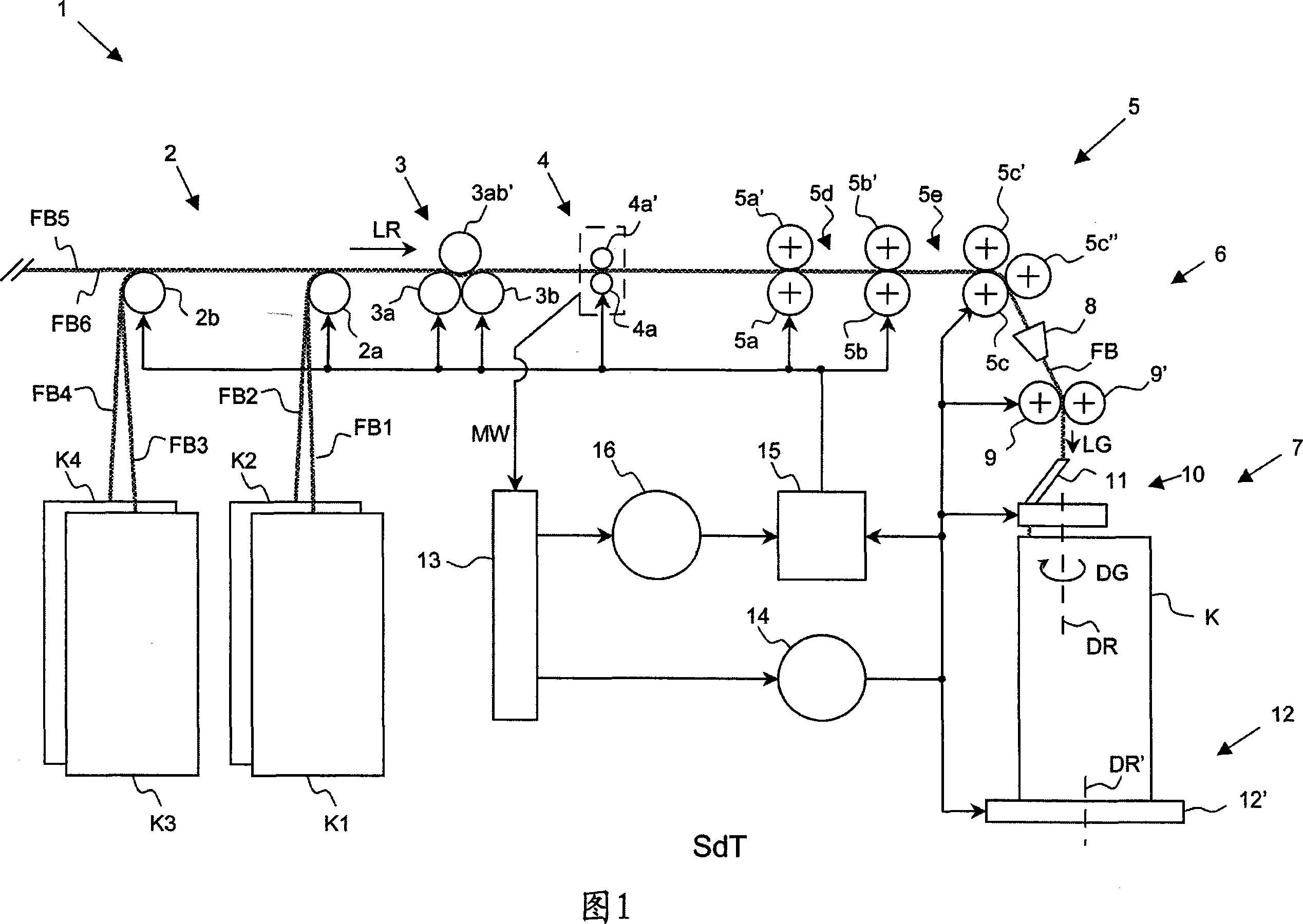

[0043] FIG. 1 shows a schematic side view of a spinning frame 1 as an example of a spinning preparation machine 1 . The fiber slivers FB1 , FB2 , FB3 , FB4 , FB5 and FB6 in front of the spinning frame 1 are conveyed together in the direction of movement LR on the feed table 2 , the inlet roller device 3 , the inlet sensor device 4 and the drawing system 5 . The fiber slivers FB1 , FB2 , FB3 , FB4 , FB5 and FB6 are then combined by the transfer device 6 to form a single compact fiber sliver FB. They are then conveyed at a defined conveying speed LG to the device 7 with which the fiber sliver FB is deposited in the sliver can K.

[0044] The feed table 2, shown schematically only, incorporates a first feed table roller 2a, which is arranged so that the first fiber sliver FB1 in front of the machine can be drawn from the placed sliver tube K1 by the drawing frame 1. The second fiber sliver FB2 can be drawn out from the sliver drum K2 placed in an offset position. A second infee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com