Gas-liquid chromatogram separate sampling device and method

A chromatographic separation and sampling device technology, which is applied in the field of preparative gas chromatographic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

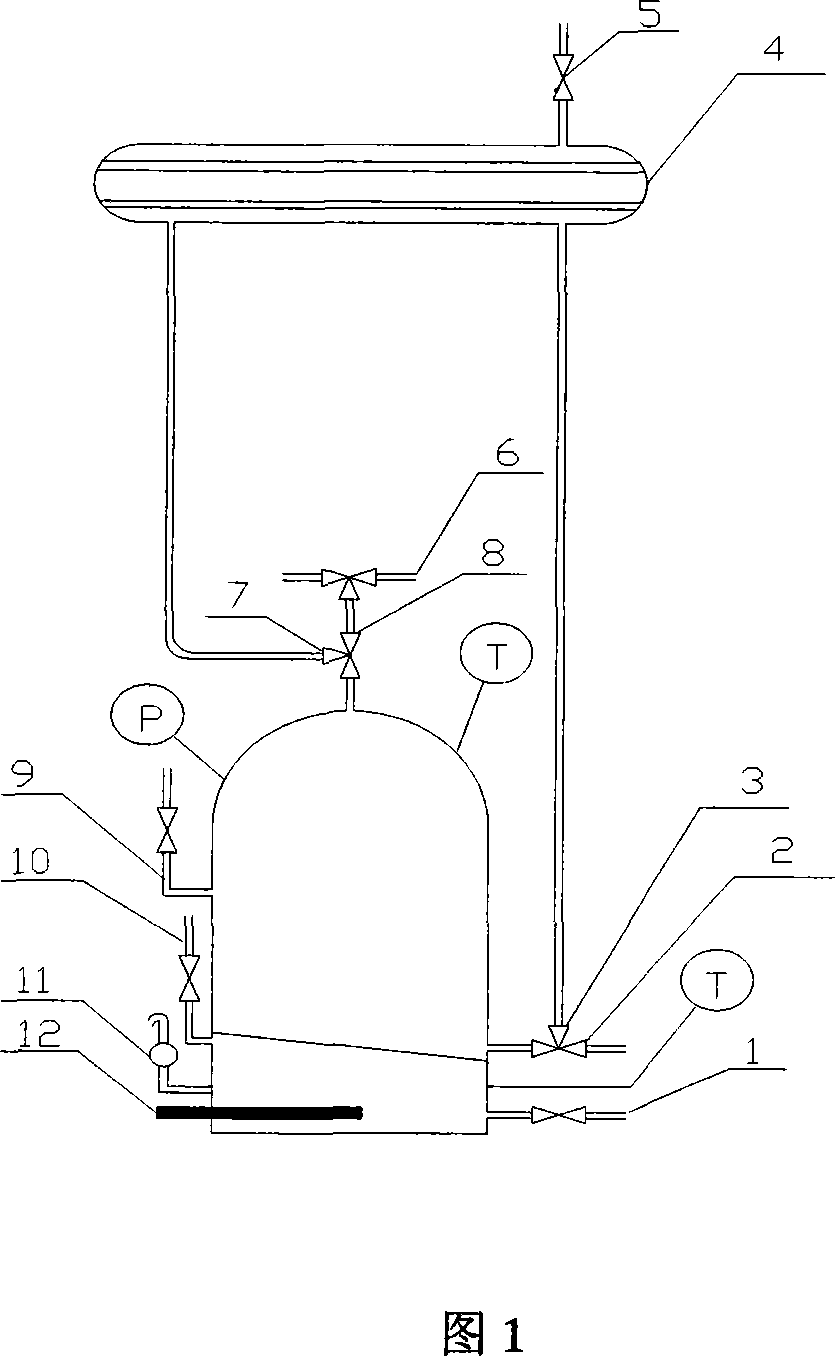

[0013] As shown in the figure, 1 is the heat transfer oil discharge port; 2 is the material discharge port; 3 is the condensate return port; 4 is the condenser; 5 is the vent valve; 6 is the carrier gas inlet; 7 is the steam entering the condenser outlet; 8 9 is the material inlet; 10 is the heat transfer oil inlet; 11-the heat transfer oil vent 12-the heating rod. The valve of the gas-liquid chromatographic separation and sampling device is a ball valve. There are three three-way valves, which are the valves connecting the atmosphere, heating kettle, and condenser; the valves connecting heating kettle, condenser, and chromatographic column; and the valves connecting heating kettle, carrier gas preheating column, and chromatographic column. The rest of the valves are two-way valves.

[0014] This experiment selects n-propanol-water solution as raw material, the feeding amount is 1600ml, and its azeotropic composition under normal pressure is 28.3% (mass fraction of water). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com