Timber drying stress detection device and method

A wood drying and detection device technology, which is applied in the direction of wood testing, material inspection products, etc., can solve the problems that the layered slicing method cannot be directly measured continuously in a timely manner, and the test accuracy is difficult to be guaranteed, and achieves the effect of simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

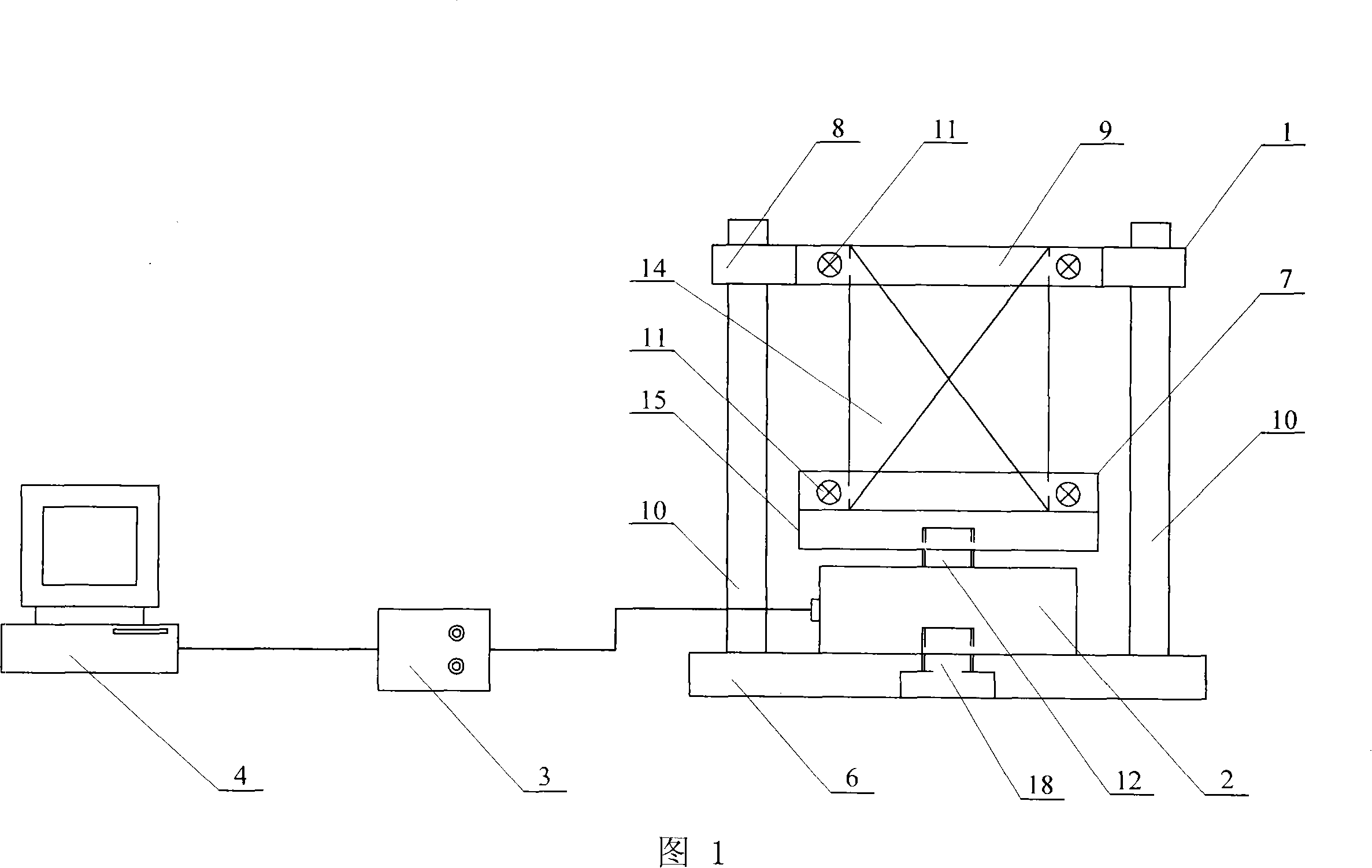

[0009] Embodiment 1: This embodiment is described in conjunction with FIG. 1 . The device of this embodiment is composed of a clamp 1, a tensile stress sensor 2, an analog-to-digital converter 3, and a computer 4; the tensile stress sensor 2 is fixed on the clamp 1 Above, the output end of the tensile stress sensor 2 is connected to the input end of the analog-to-digital converter 3 , and the output end of the analog-to-digital converter 3 is connected to the input end of the computer 4 . The model of the tensile stress sensor 2 in this embodiment is TLP-2KNHS, manufactured by Tokyo Shoki Research Institute, Japan; the model of the analog-to-digital converter 3 is DC-104R, manufactured by Tokyo Sekki Research Institute of Japan.

specific Embodiment approach 2

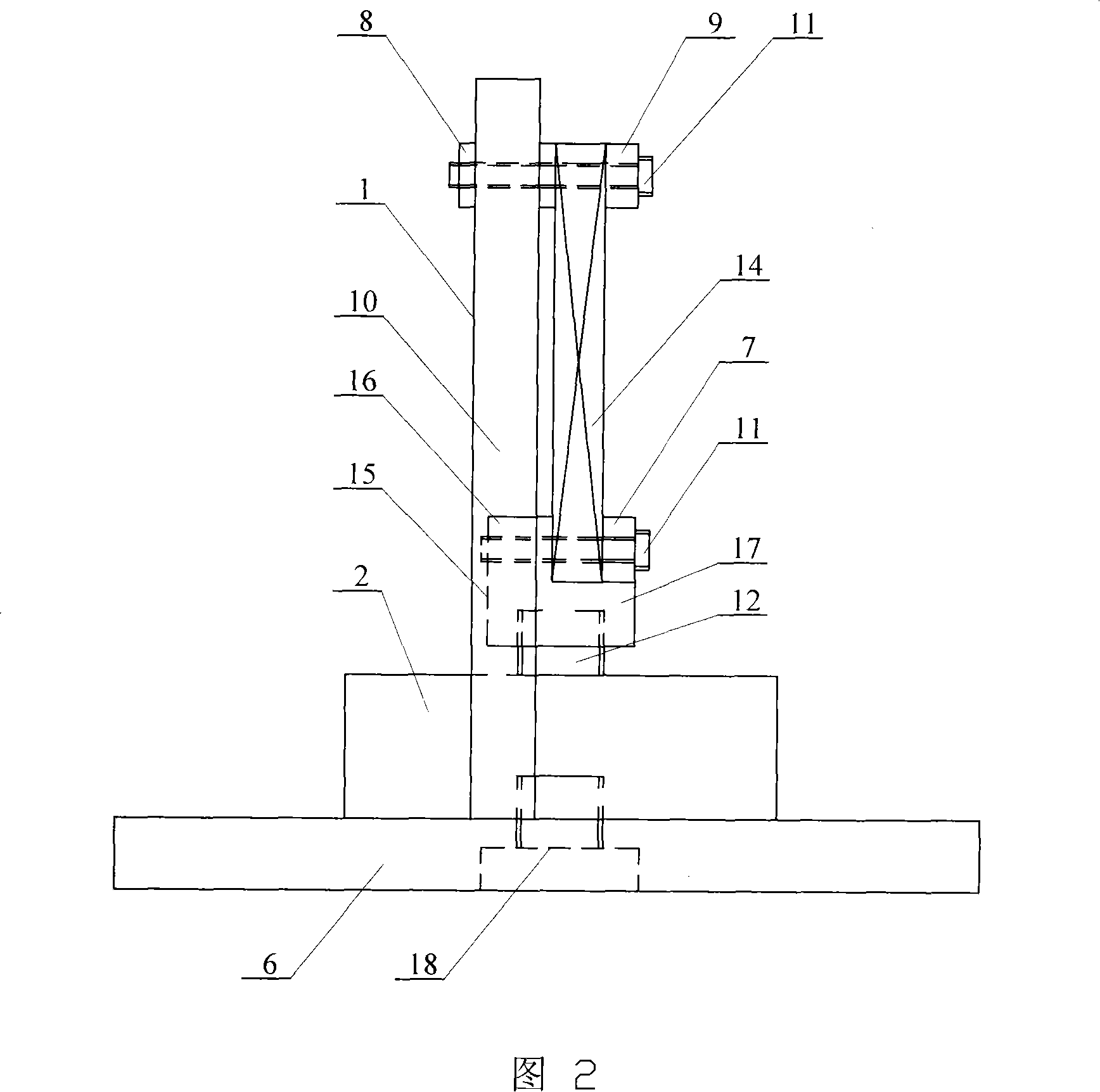

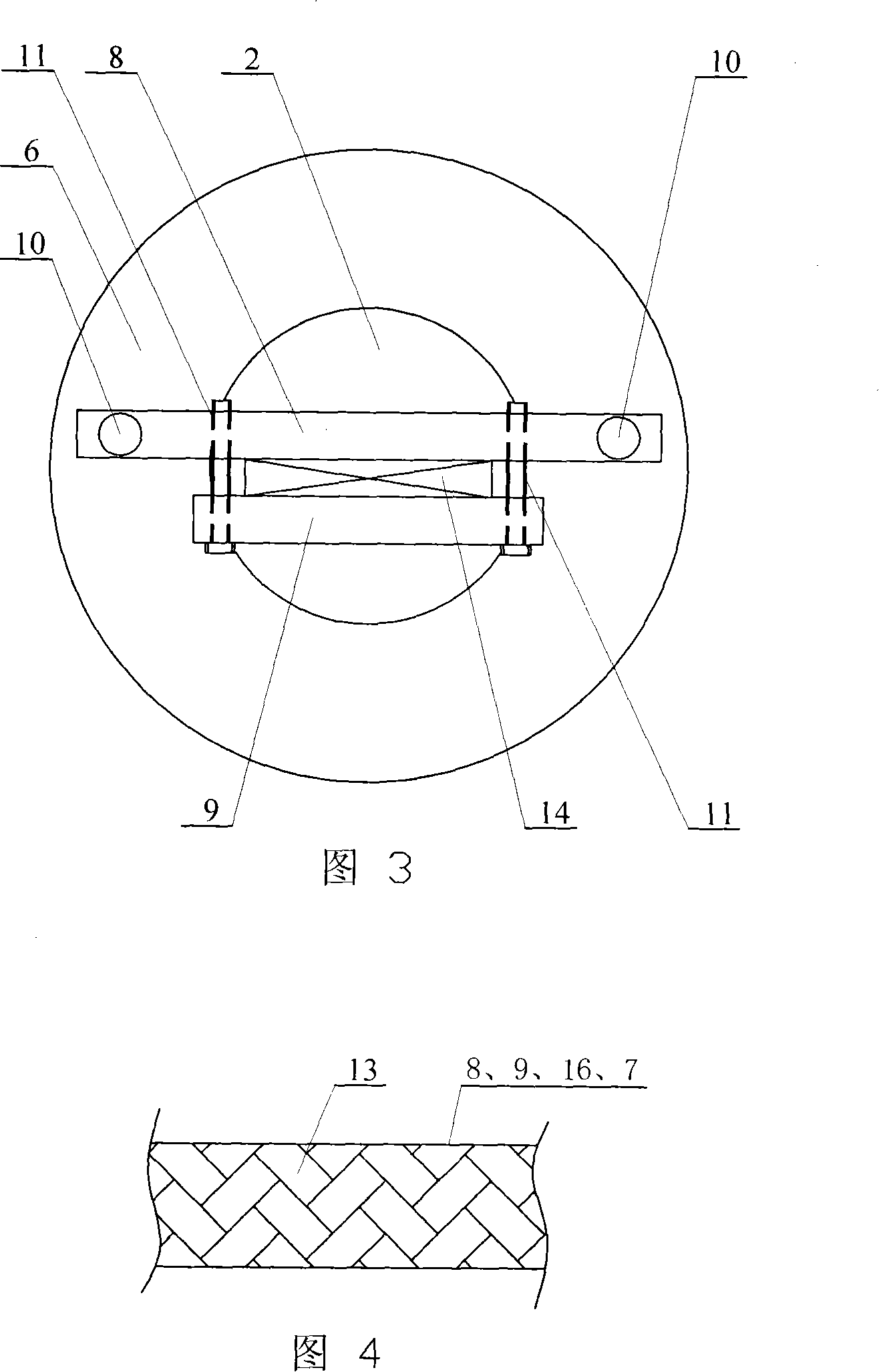

[0010] Specific Embodiment 2: This embodiment is described in conjunction with FIGS. 1 to 3. The fixture 1 of this embodiment consists of a long upper fixture plate 8, a short upper fixture plate 9, a short lower fixture plate 7, an L-shaped lower fixture plate 15, two A pillar 10, four bolts 11, a base 6 and connecting bolts 18 are formed; the two pillars 10 are fixed on the base 6 in parallel in the vertical direction, and the upper ends of the two pillars 10 are connected to the two ends of the long upper fixture plate 8 Fixed connection, the short upper jig plate 9 is located directly in front of the long upper jig plate 8, the vertical plate 16 of the L-shaped lower jig plate 15 is located below the long upper jig plate 8, and the short lower jig plate 7 is located on the short upper jig plate Just below the plate 9, and the short lower fixture plate 7 is installed on the horizontal plate 17 of the L-shaped lower fixture plate 15, between the two ends of the short upper fi...

specific Embodiment approach 3

[0011] Specific embodiment three: This embodiment is described in conjunction with Fig. 2 and Fig. 4, the inner side of the long upper jig plate 8 and the short upper jig plate 9 of this embodiment, and the vertical plate 16 of the L-shaped lower jig plate 15 and the short lower jig plate. Knurls 13 are respectively provided on the corresponding inner surfaces between the clamping plates 7 . Such setting can increase the frictional force between the clamp 1 and the wood test piece 14 to ensure that the wood test piece 14 is firmly clamped on the clamp 1 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com