Backlight module and lamp possessing direct type light guiding board

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problem of low brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Some embodiments of the present invention are described in detail as follows. However, the invention may be practiced broadly in other embodiments than those described in detail, and the scope of the invention is not limited only by the claims.

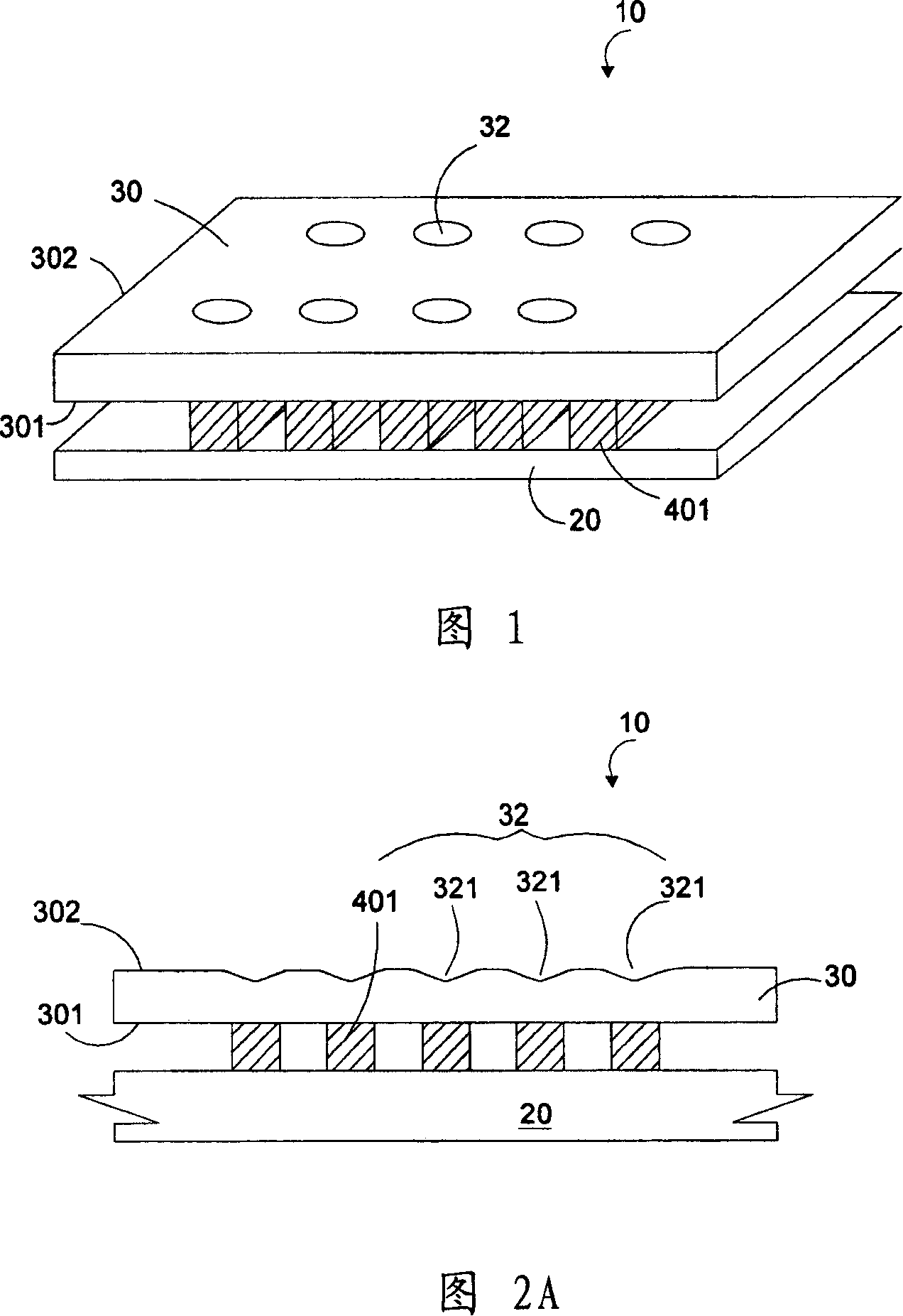

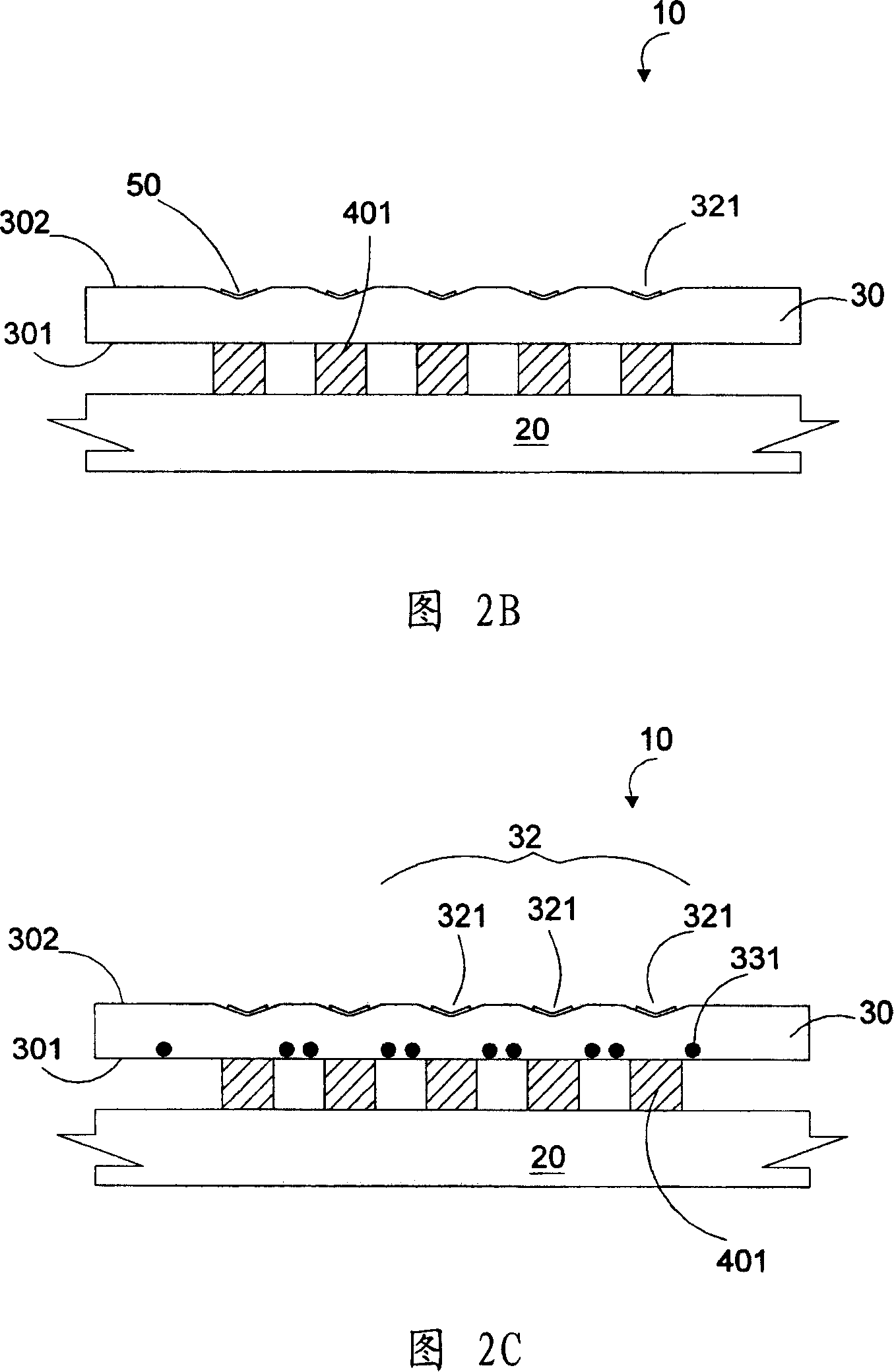

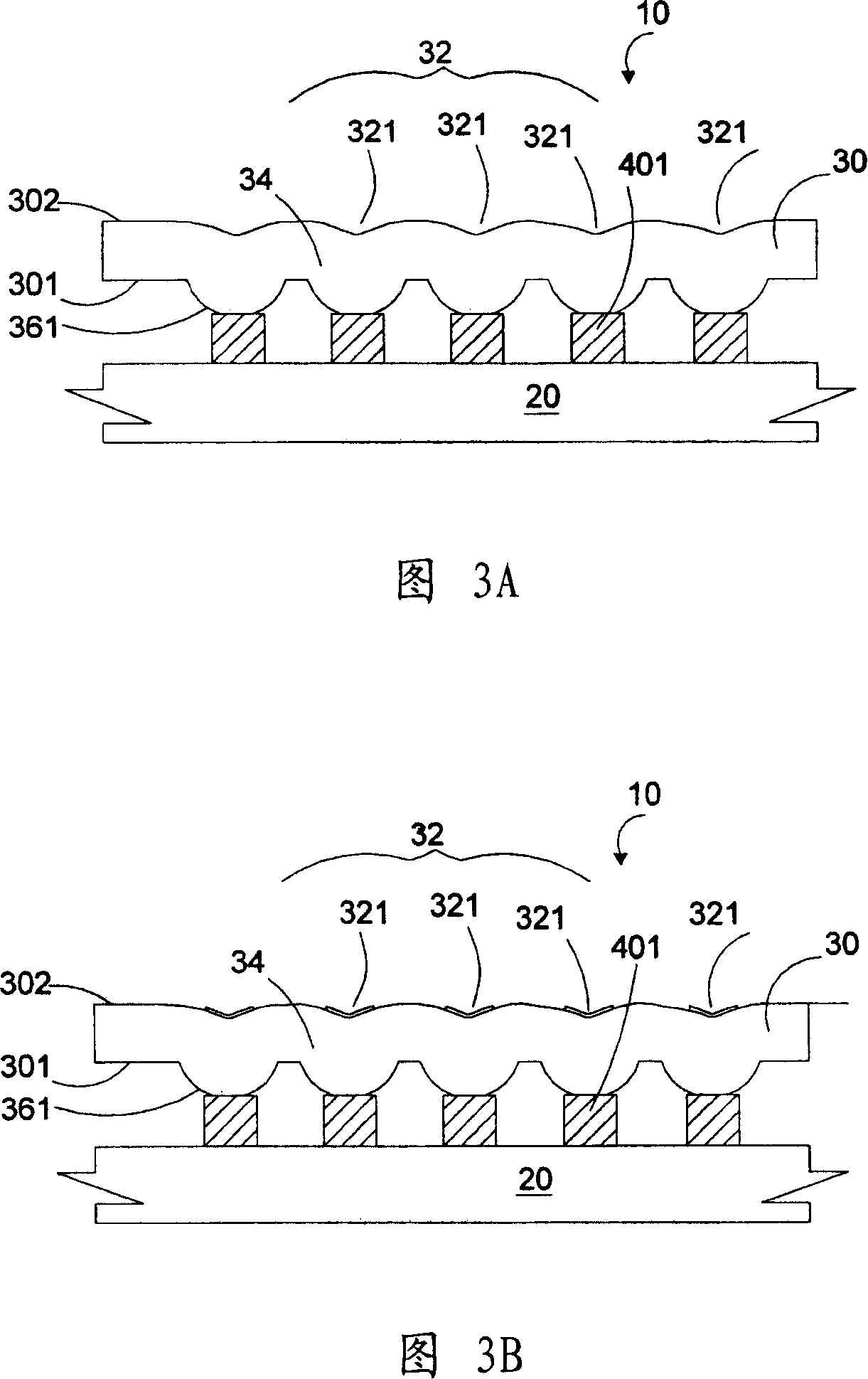

[0030] Please refer to FIG. 1 , which shows a top view of a backlight module with a direct light guide plate disclosed by the present invention. The backlight module 10 includes a printed circuit board 20 , a plurality of LEDs 401 and a light guide plate 30 having a light incident structure 32 . A plurality of light emitting diodes 401 can be arranged on the printed circuit board 20 in an array or random arrangement to provide light sources of various wavelengths as required. Here, the light incident structure 32 is set corresponding to a plurality of LED assemblies 401, and these LED assemblies 401 include a plurality of LED chips, which may be LED chips with different wavelengths, such as white LED chips or RGB LED chips. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com