Aluminum electrolytic capacitor making process

A technology of aluminum electrolytic capacitors and manufacturing processes, which is applied in the direction of capacitor manufacturing, electrolytic capacitors, capacitors, etc., can solve problems such as shortened product life, and achieve the effects of prolonging service life, stable performance, and prolonging product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

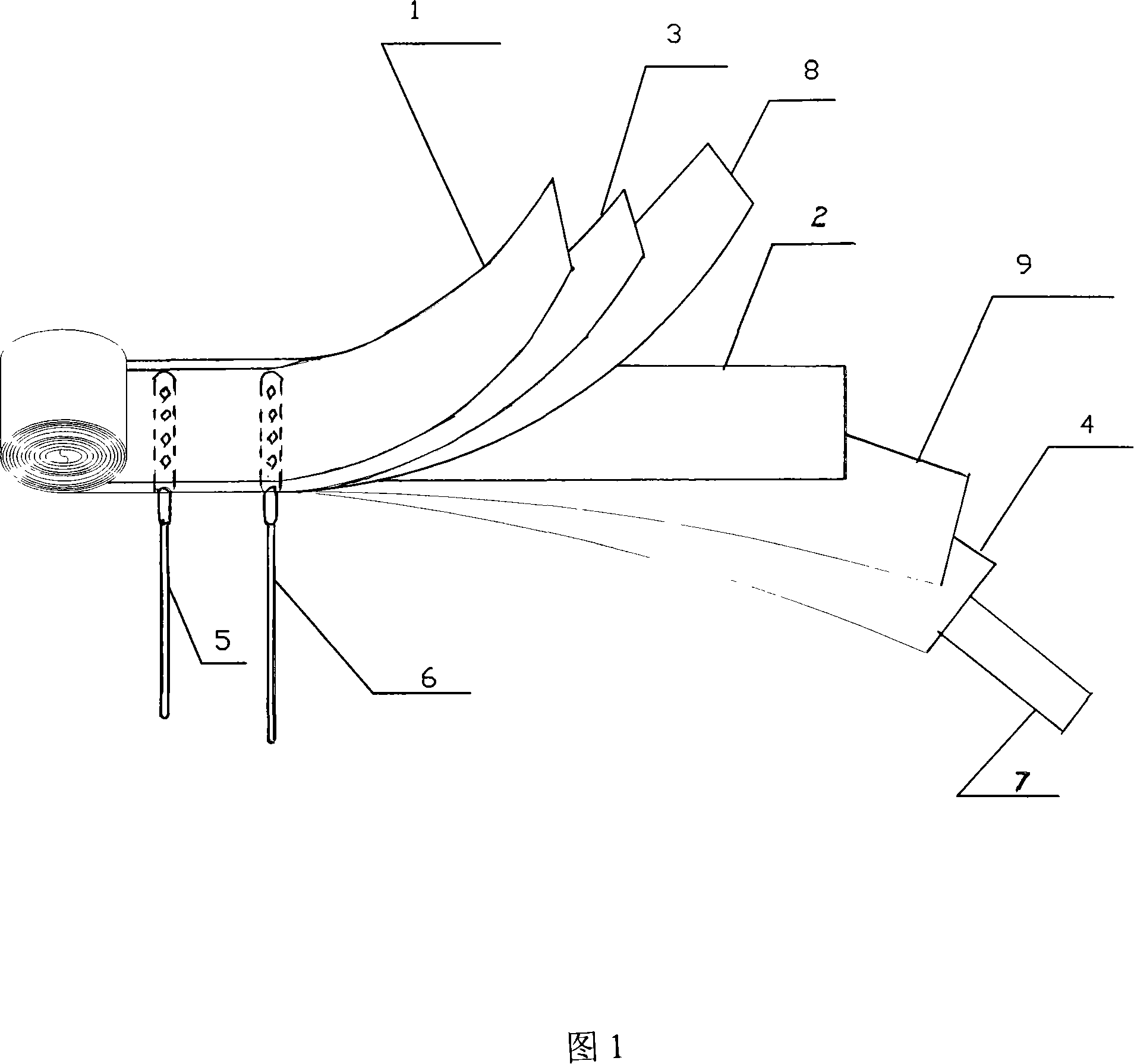

[0017] As shown in Figure 1, it is a schematic structural diagram of an aluminum electrolytic capacitor. The aluminum electrolytic capacitor is composed of an anode foil 1, a cathode foil 2, a electrolytic paper 3, b electrolytic paper 4, a negative guide pin 5, and a positive guide pin 6. Composed of anti-loosening tape 7, c electrolytic paper 8 and d electrolytic paper 9.

[0018] During processing, the tongues of the positive guide pin 6 and the negative guide pin 5 are connected to the positive electrode foil 1 and the negative electrode foil 2 respectively by riveting. Place the front ends of the initially processed anode foil 1 and cathode foil 2 together on a cylindrical shaft; add two layers between the anode foil 1 and the cathode foil 2, that is, a electrolytic paper 3 and c electrolytic paper 8, and a The front ends of electrolytic paper 3 and c electrolytic paper 8 are also placed together at a cylindrical rotating shaft; two layers, namely b electrolytic paper 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com