A white light LED and its making method

An LED chip, white light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low brightness of white LEDs, unsuitable for street lamps, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

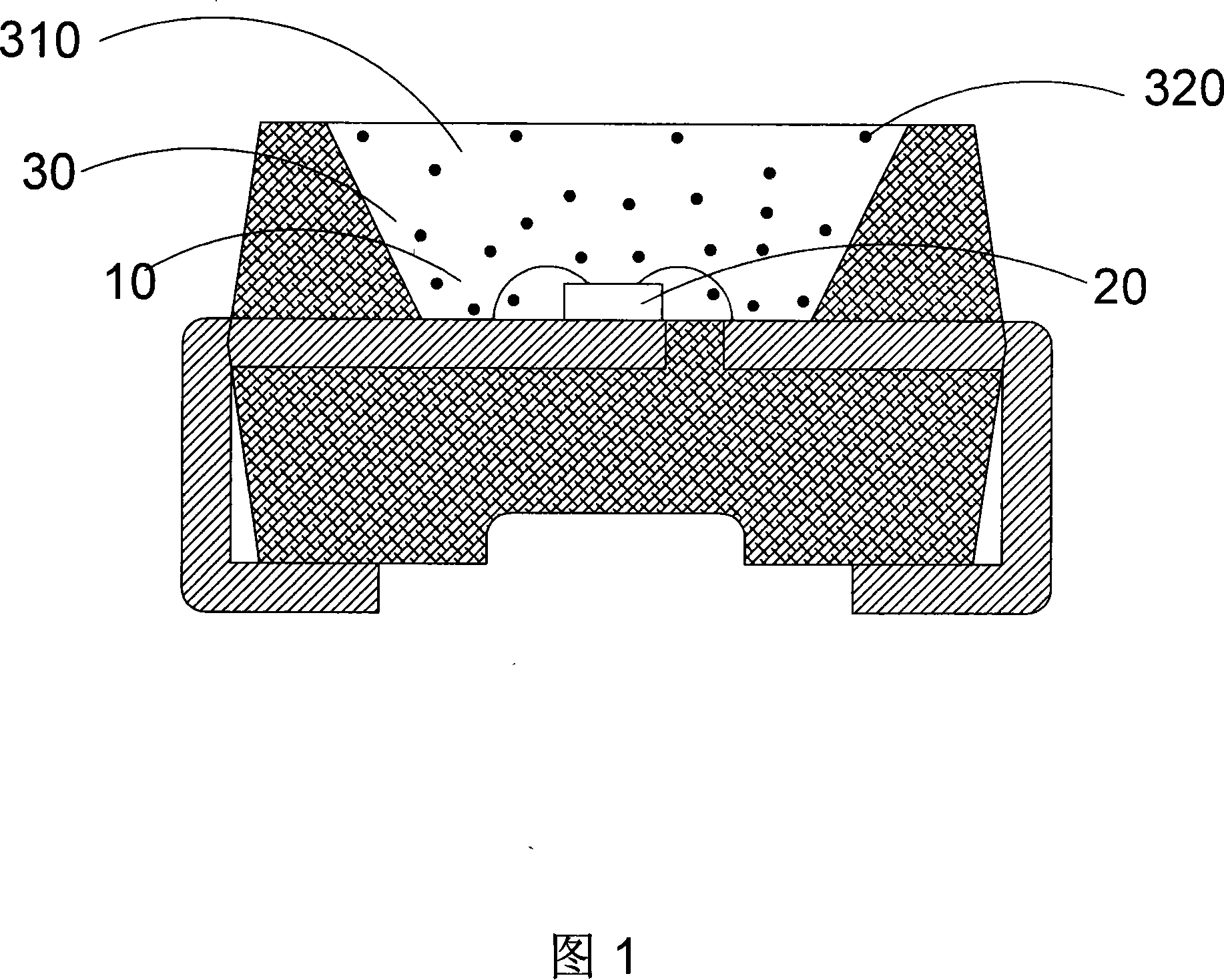

Image

Examples

example 1

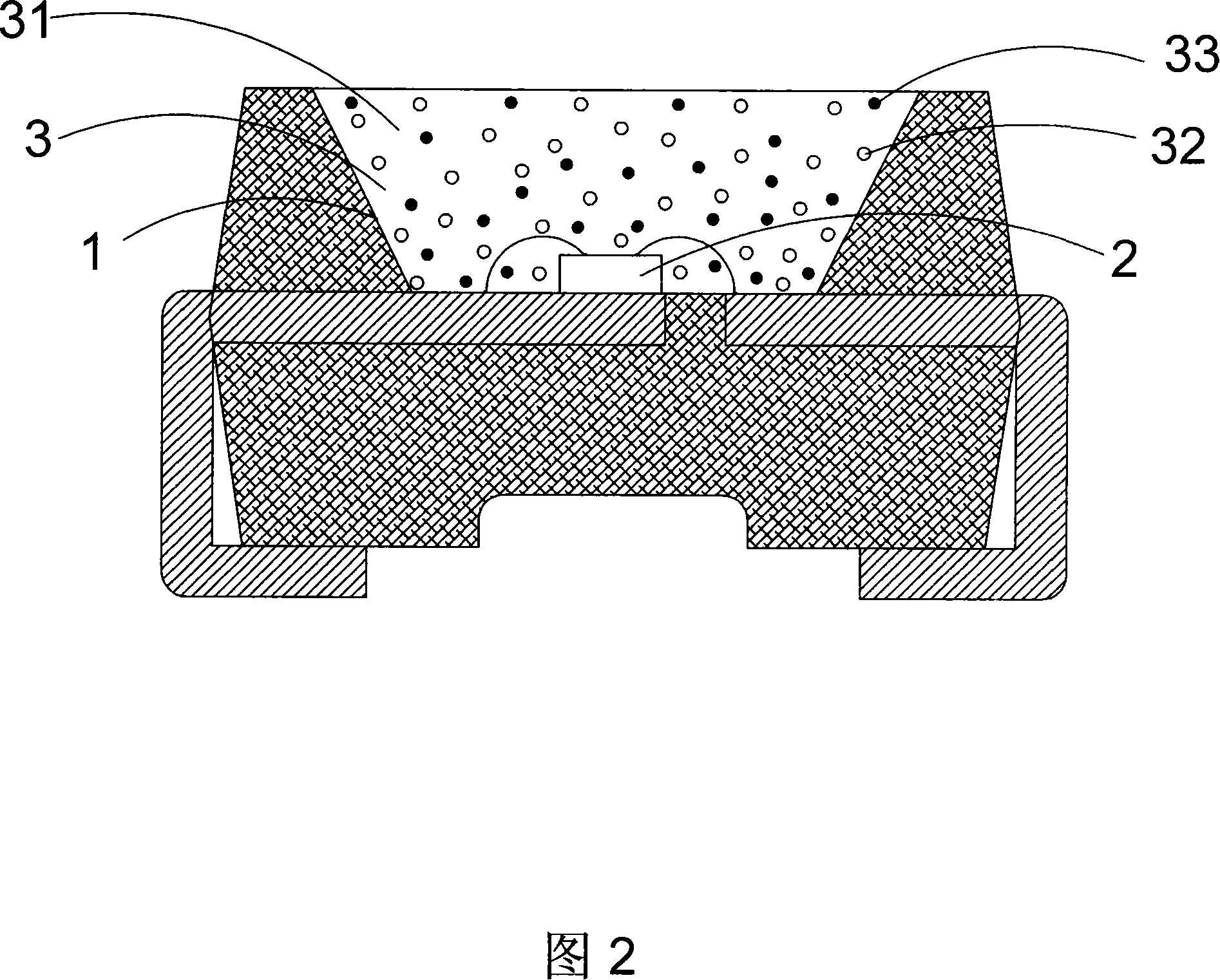

[0020] Example 1, using a blue LED chip 2 with an excitation wavelength of 460.0-462.5nm, a phosphor 3 composed of glue 31, a yellow phosphor 32 stimulated to produce 555nm, and an orange phosphor 33 excited to produce 590nm, the yellow phosphor 32 occupies The phosphor weight ratio is 6.65%, the orange phosphor 33 accounts for 1.33% of the phosphor 3 weight ratio, and the rest is glue. The above phosphor 3 is stirred evenly, injected into the cavity 1, and then dried to form a white LED. The spectrum is shown in Figure 5. Its color temperature is about 4800K, display index Ra is greater than 80, and its excitation efficiency is higher than that of yellow phosphor, reaching 49LM / W.

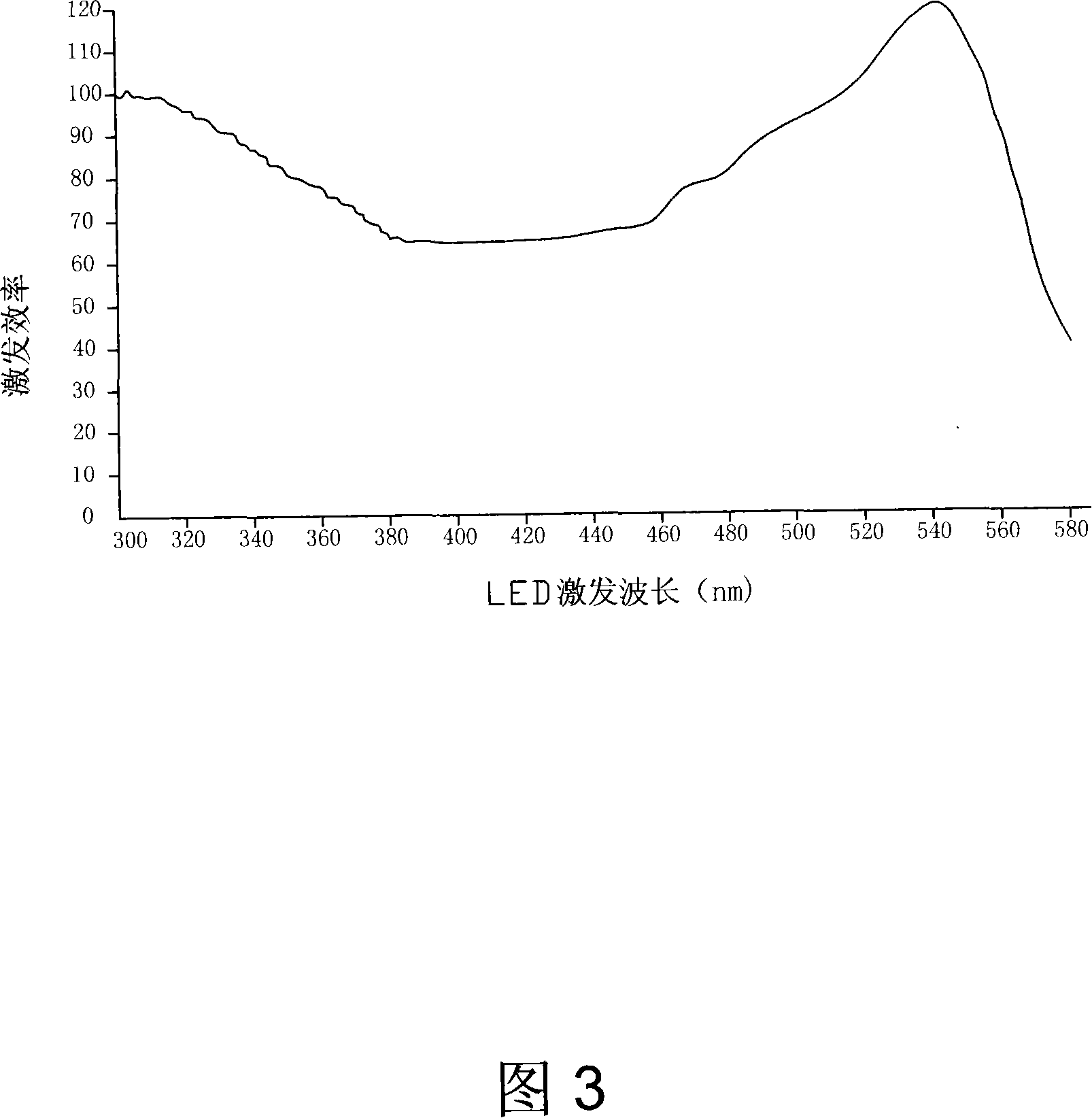

[0021] Compared with the color temperature of the yellow phosphor powder excited by the previous blue LED, as shown in Figure 4, there are only two peaks, one is the peak of the blue LED; the other is the peak after the yellow phosphor is excited, which is near 555nm, and the peak is high. The co...

example 2

[0022] Example 2, using a blue LED chip 2 with an excitation wavelength of 460.0-462.5nm, a phosphor 3 composed of glue 31, a yellow phosphor 32 stimulated to produce 555nm, and an orange phosphor 33 excited to produce 590nm, the yellow phosphor 32 occupies The phosphor weight ratio is 6.55%, the orange phosphor 33 accounts for 2.62% of the phosphor 3 weight ratio, and the rest is colloid. The above phosphor 3 is stirred evenly, injected into the cavity 1, and then dried to form a white LED. The spectrum is shown in Figure 6. Its color temperature is around 3800K, and its excitation efficiency reaches 52LM / W.

example 3

[0023] Example 3, using a blue LED chip 2 with an excitation wavelength of 460.0-462.5nm, a phosphor 3 composed of glue 31, a yellow phosphor powder 32 stimulated to produce 555nm, and an orange phosphor powder 33 excited to produce 590nm, the yellow phosphor powder 32 occupies The phosphor weight ratio is 6.47%, the orange phosphor powder 33 accounts for 3.88% of the phosphor 3 weight ratio, and the rest is glue. The above phosphor 3 is stirred evenly, injected into the cavity 1, and then dried to form a white LED. The spectrum is shown in Figure 7. Its color temperature is around 3300K, and its excitation efficiency reaches 54LM / W.

[0024] The above tests show that as the weight ratio of the orange phosphor 33 to the phosphor 3 increases, the color temperature of the white LED of the present invention decreases, but the brightness increases. Under the same color temperature, the color rendering index of the white LED of the present invention is higher than that of the prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com