Flat video display device

An image display, flat-panel technology, applied in the direction of instruments, static electricity, electrical components, etc., can solve the problems of increasing labor costs, prolonging the overall operation process, etc., to achieve the effect of enhancing strength and stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention capable of achieving the above objects will be described below with reference to the accompanying drawings. In the description of this embodiment, the same name and the same symbol are used for the same structure, and additional description of the structure will be omitted later.

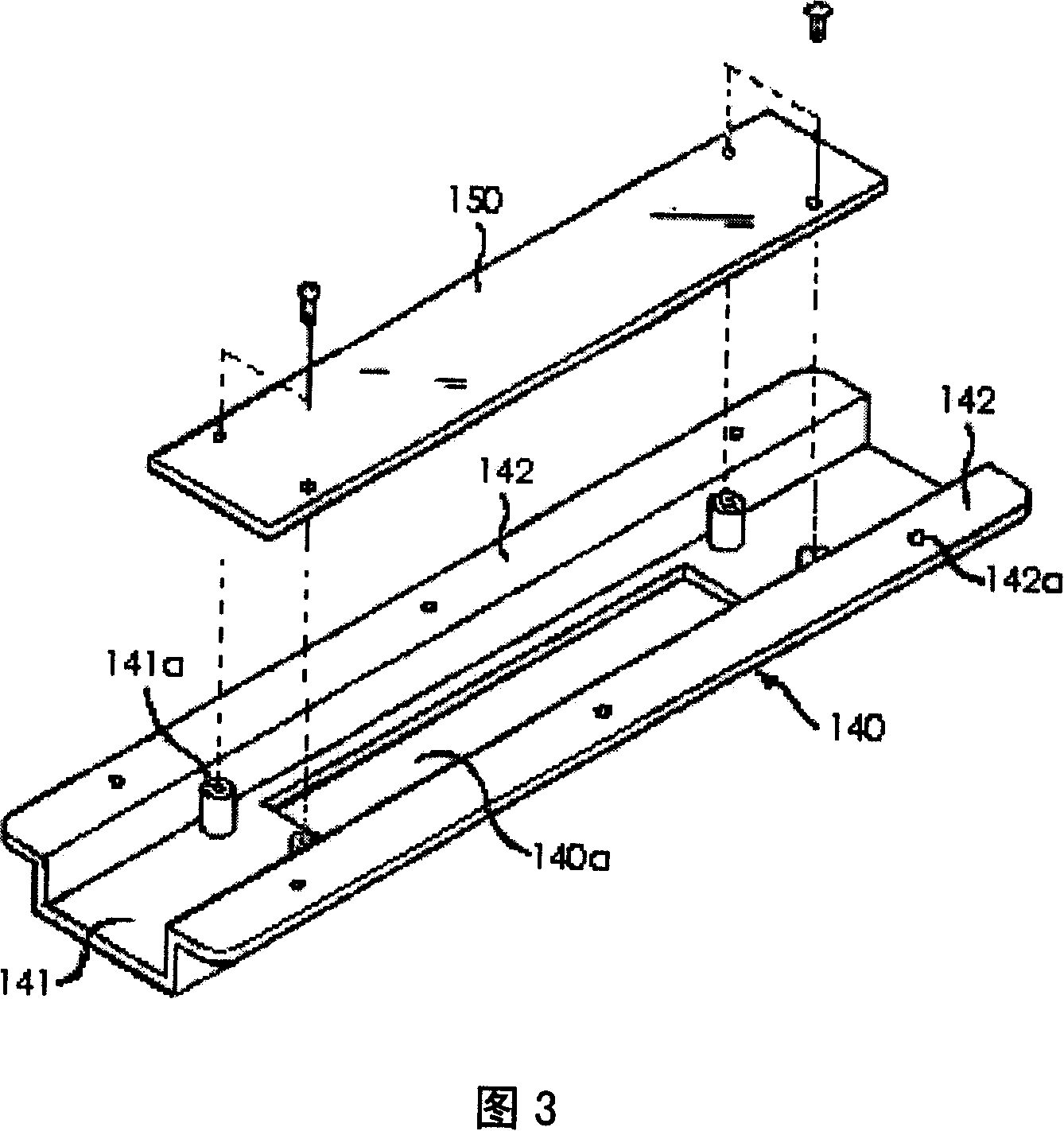

[0038] Fig. 2 is a schematic diagram of a state in which a support frame and a printed circuit board are connected on the front panel based on the present invention.

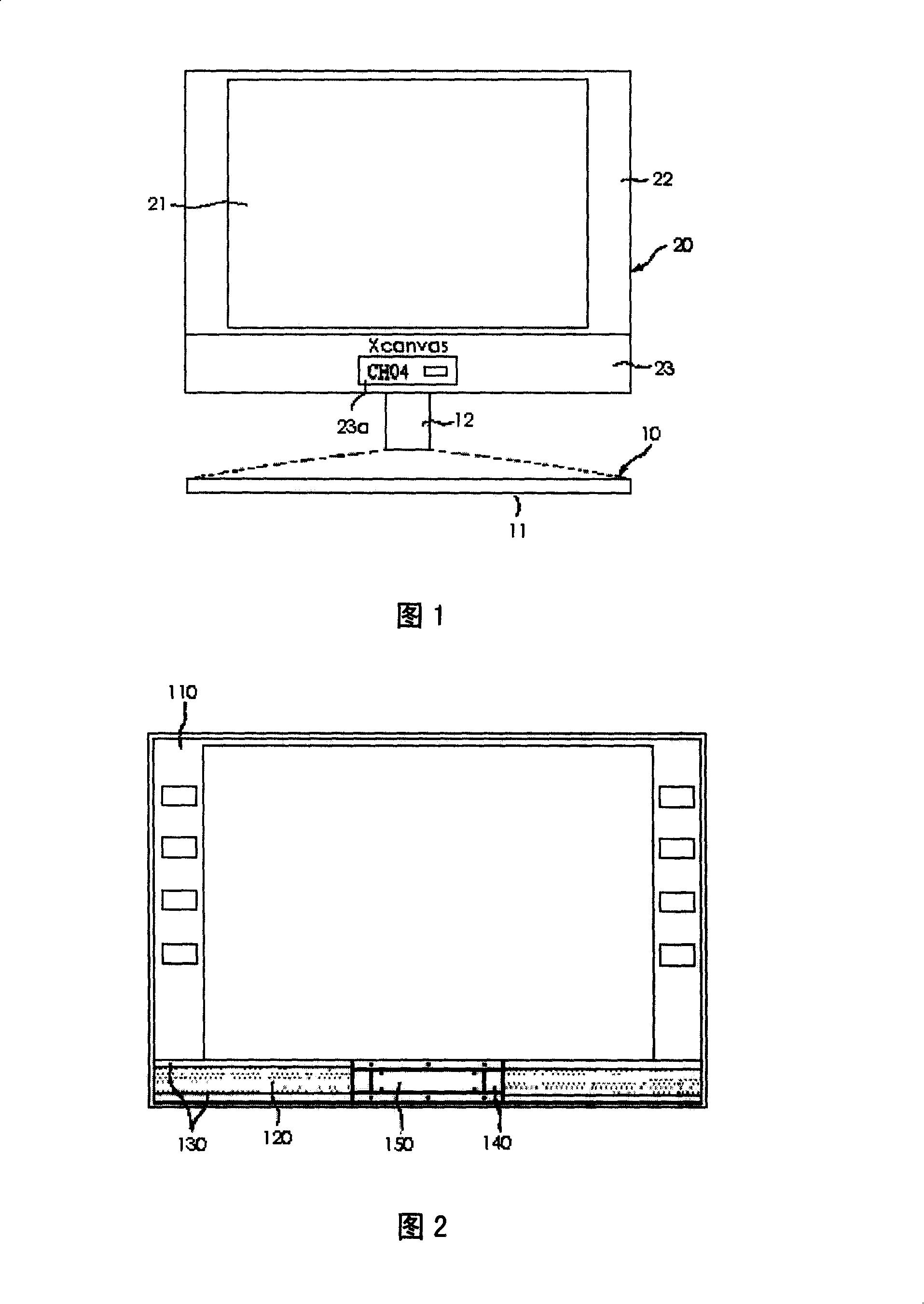

[0039] Referring to FIG. 2 , the flat panel image display device based on the present invention is composed of a front panel 110 , a decorative plate 120 , a metal frame 130 , a support frame 140 and a printed circuit board 150 .

[0040] The above-mentioned front panel 110 is connected to the front portion of the display module 21 (referring to FIG. 1 ) for displaying images, and is responsible for supporting the display module 21; The visual beauty of the installation.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com