A ceramic armour element for use in armour

A technology of ceramics and components is applied in the field of armor panels providing anti-ballistic performance, which can solve the problems of falling off of tiles and adjacent tiles, destroying panels, and reducing the protective performance of panels, so as to improve the anti-ballistic performance and improve the level of protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

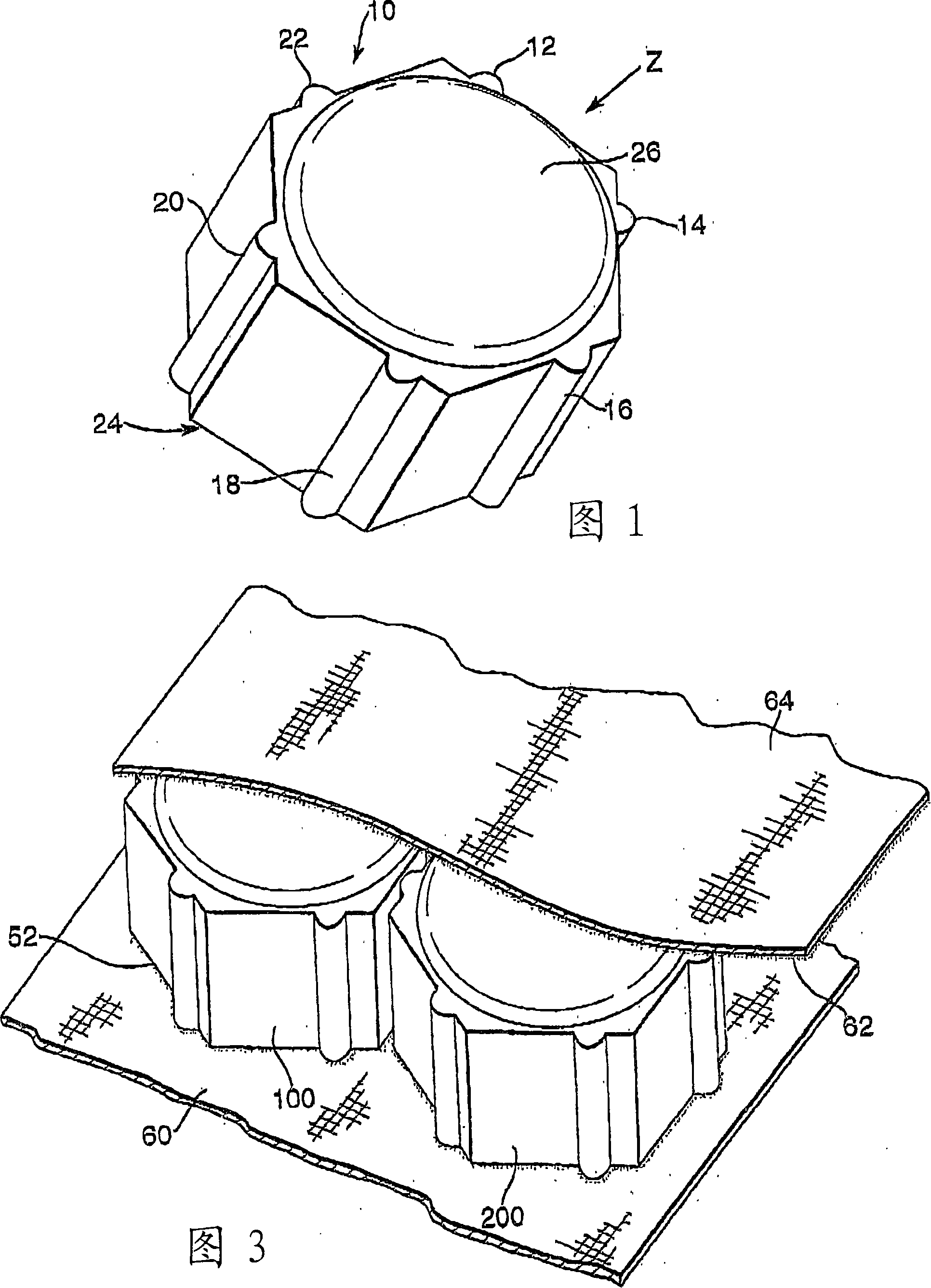

[0021] FIG. 1 shows a ceramic armor element 10 . When the ceramic armor element 10 is viewed in the direction indicated by Z, the ceramic armor element has a hexagonal cross-sectional shape. The ceramic armor element 10 has lugs 12 , 14 , 16 , 18 , 20 , 22 on each side of the ceramic armor element. The element has a flat lower surface 24 and a convex upper surface 26 . The convex upper surface serves to dissipate the energy from the initial impact of the projectile over a larger area than if the element had a flat upper surface.

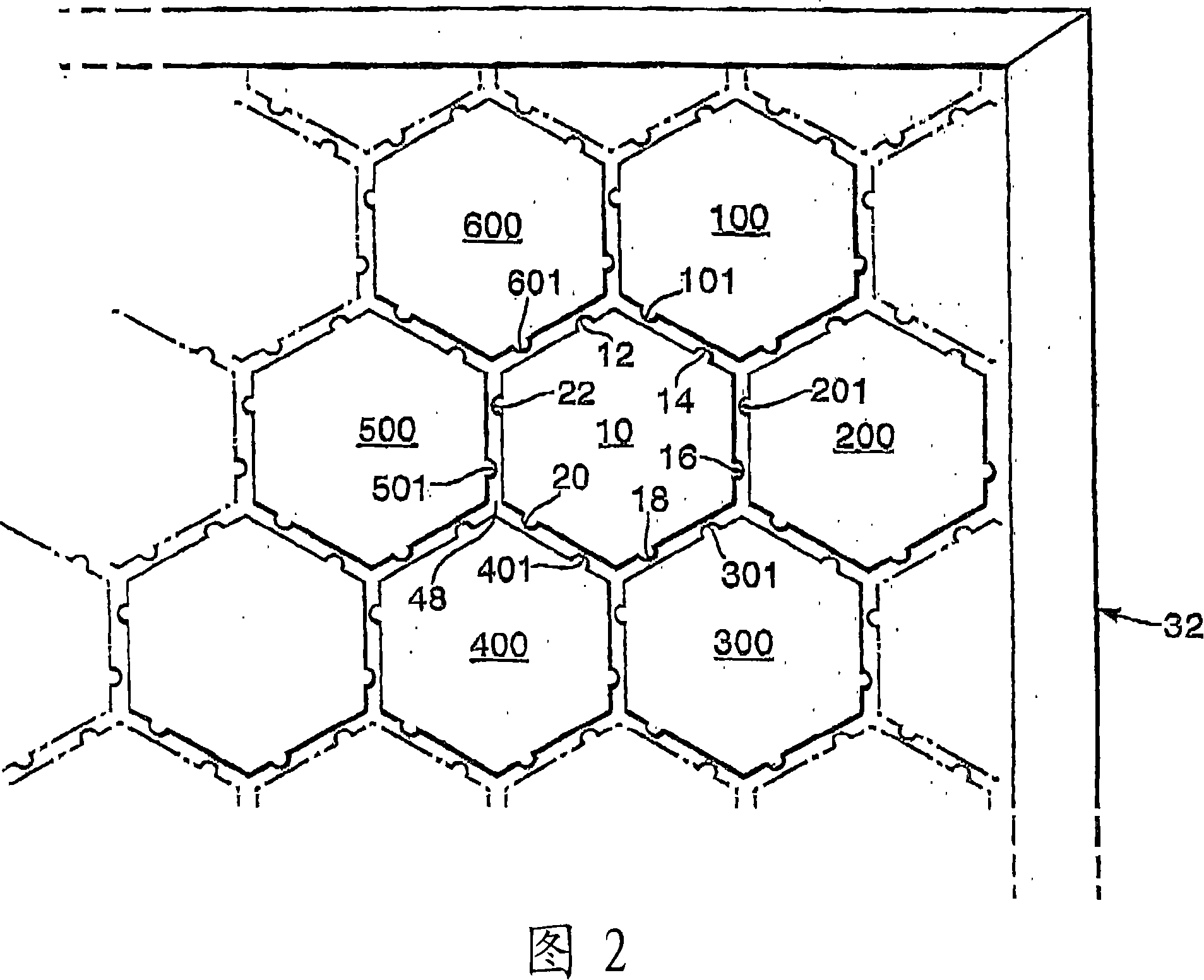

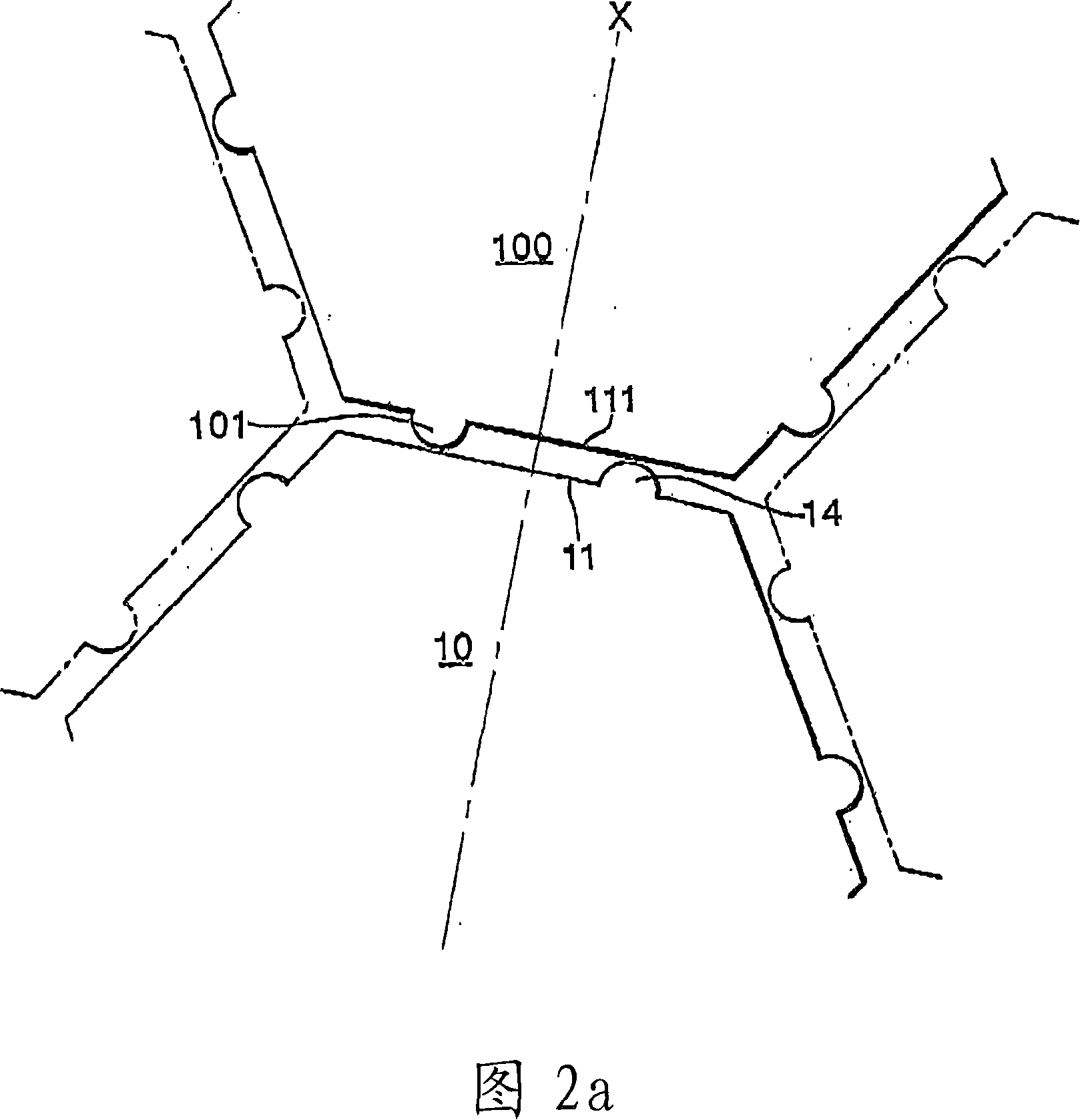

[0022] FIG. 2 shows an array of hexagonal ceramic armor elements comprising element 10 and identical elements 100 , 200 , 300 , 400 , 500 , 600 . The hexagonal array is arranged such that the lugs 12 , 14 , 16 , 18 , 20 , 22 on the ceramic armor element 10 cooperate with adjacent ceramic armor elements 100 , 200 , 300 , 400 , 500 , 600 . The lugs 101, 201, 301, 401, 501, 601 on the adjacent elements 100, 200, 300, 400, 500, 600 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com