Vacuum cleaners with air flow regulation upstream of the motor

A technology of regulating device and vacuum cleaner, applied in the direction of vacuum cleaner, flow control, control/regulation system, etc., can solve the problems of reducing air flow, increasing negative pressure, reducing suction quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

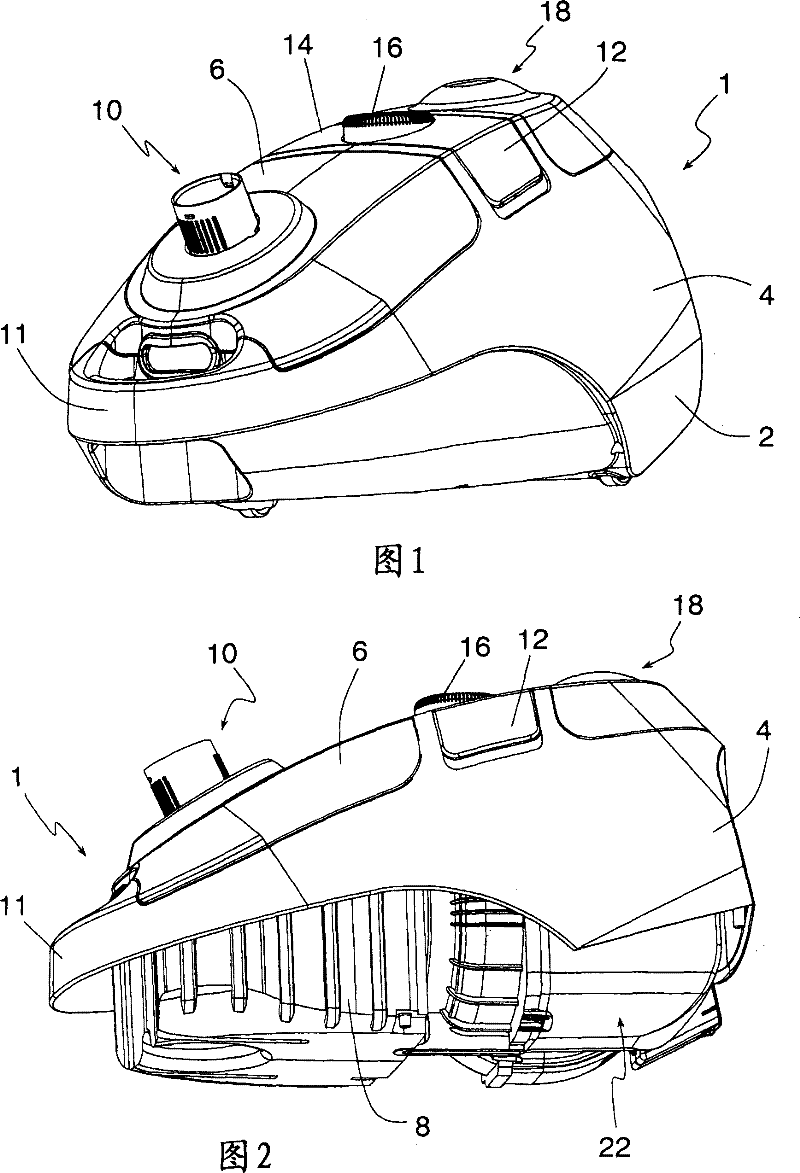

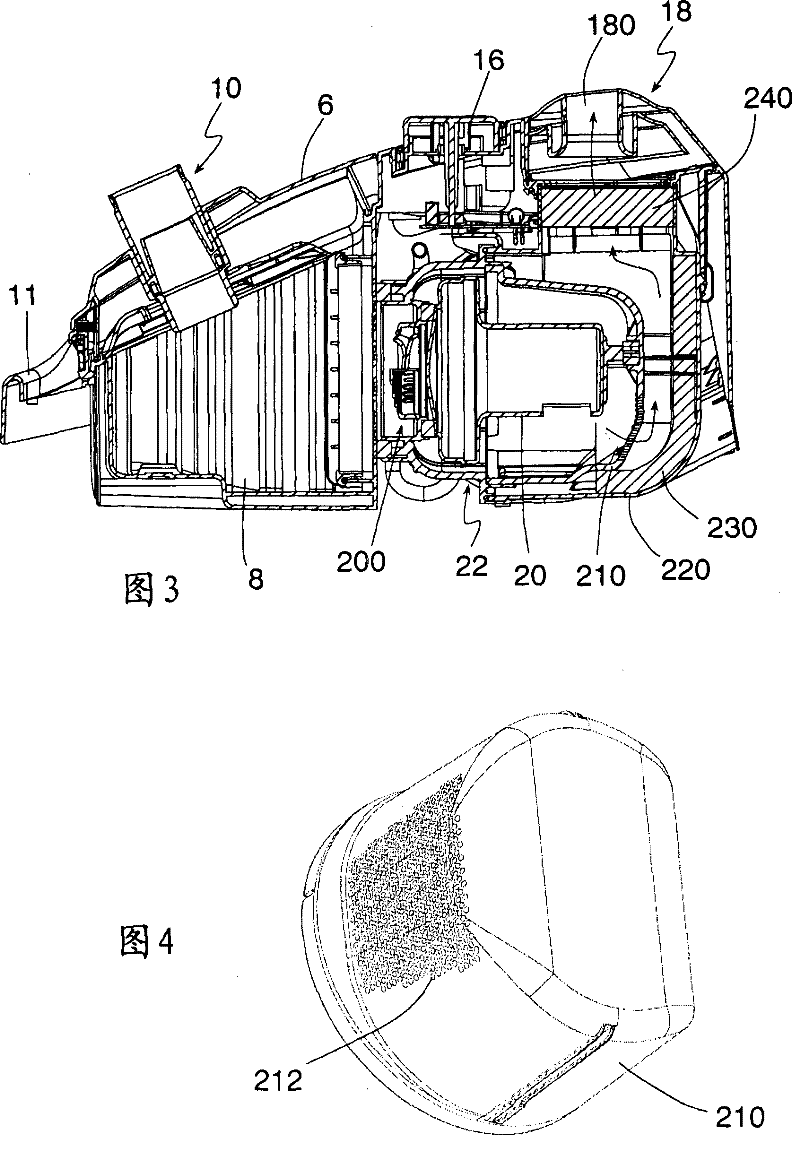

[0039] [39] If Figure 1-3 As shown, the vacuum cleaner 1 consists of a vacuum cleaner body consisting of a lower body 2, an upper body 4 and a cover 6 which closes the slot 8 of the vacuum cleaner bag. The rear surface of the slot 8 includes openings in air communication with the motor chamber.

[0040] [40] The cover 6 is also provided with a connection 10 for connecting the suction pipe to the storage bag for the air filter and suction waste. The circular portion of the front of the upper body forms the handle 11 .

[0041] [41] The upper body 4 is also provided with mechanisms 12, 14 and 16 for respectively controlling the start and stop of the motor, the winding of the electric wire and the power of the motor. Bleeding of air from the motor is achieved through an assembly 18 located on the upper body 4 at the rear of the device.

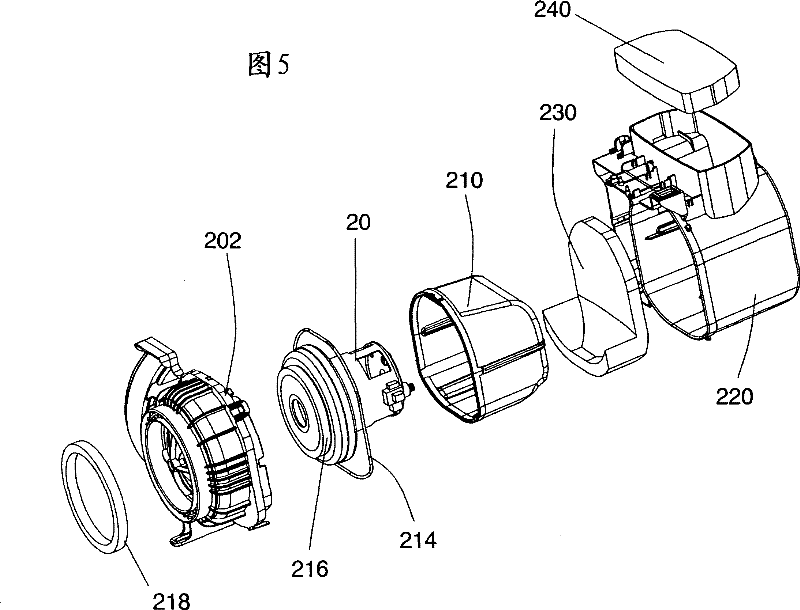

[0042] [42] The vacuum cleaner motor 20 is located in a fairing 22 connected to the air outlet opening of the collection bag tank 8 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com