Seal compressor

A technology of compressors and compression parts, which is applied in the direction of mechanical equipment, engine functions, engine components, etc., can solve the problems of cooling fan sound leakage, large guide parts, and large-scale packaged compressors, etc., to achieve noise reduction and noise suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

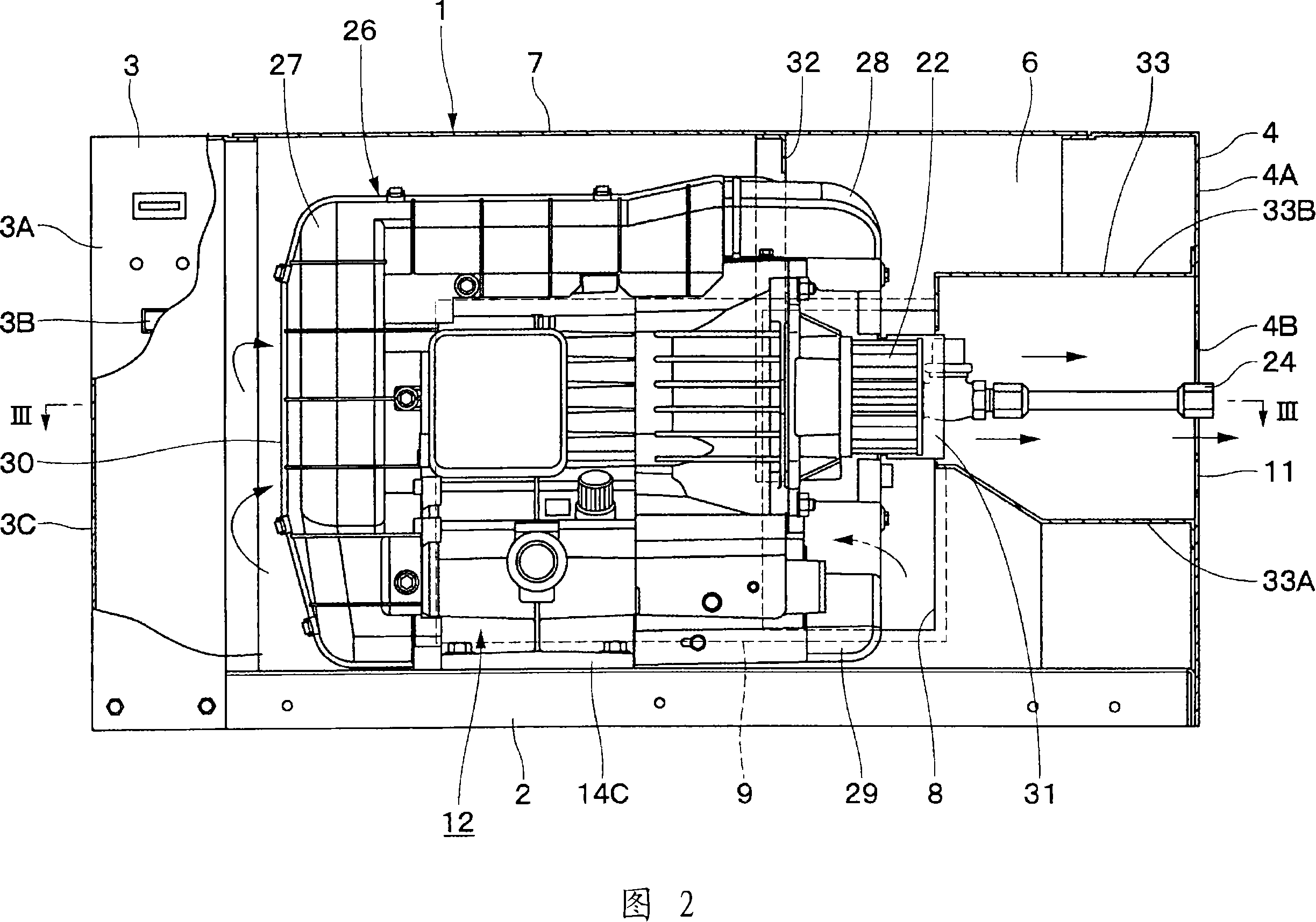

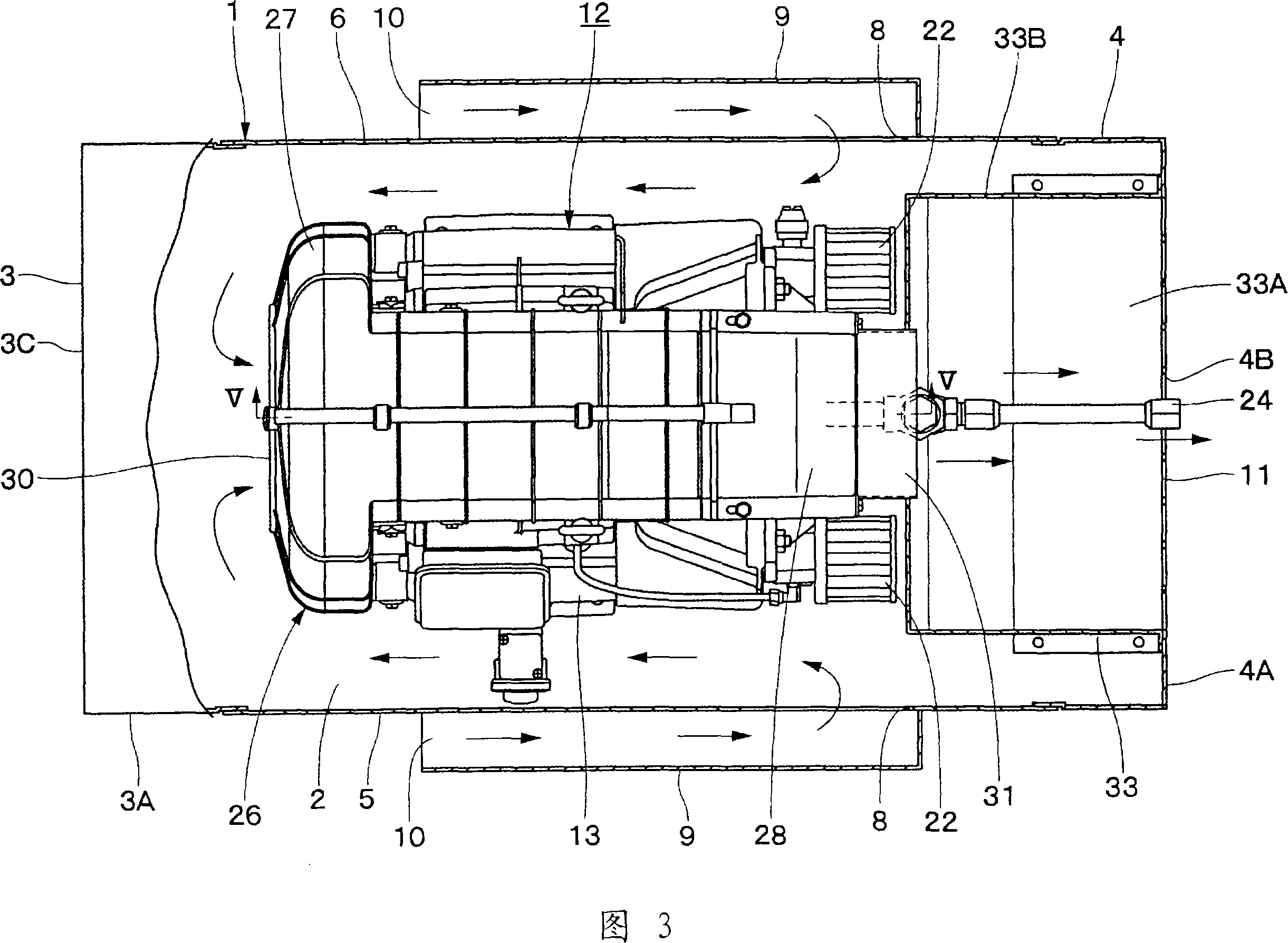

[0086] Hereinafter, a packaged compressor according to an embodiment of the present invention will be described in detail with reference to the drawings.

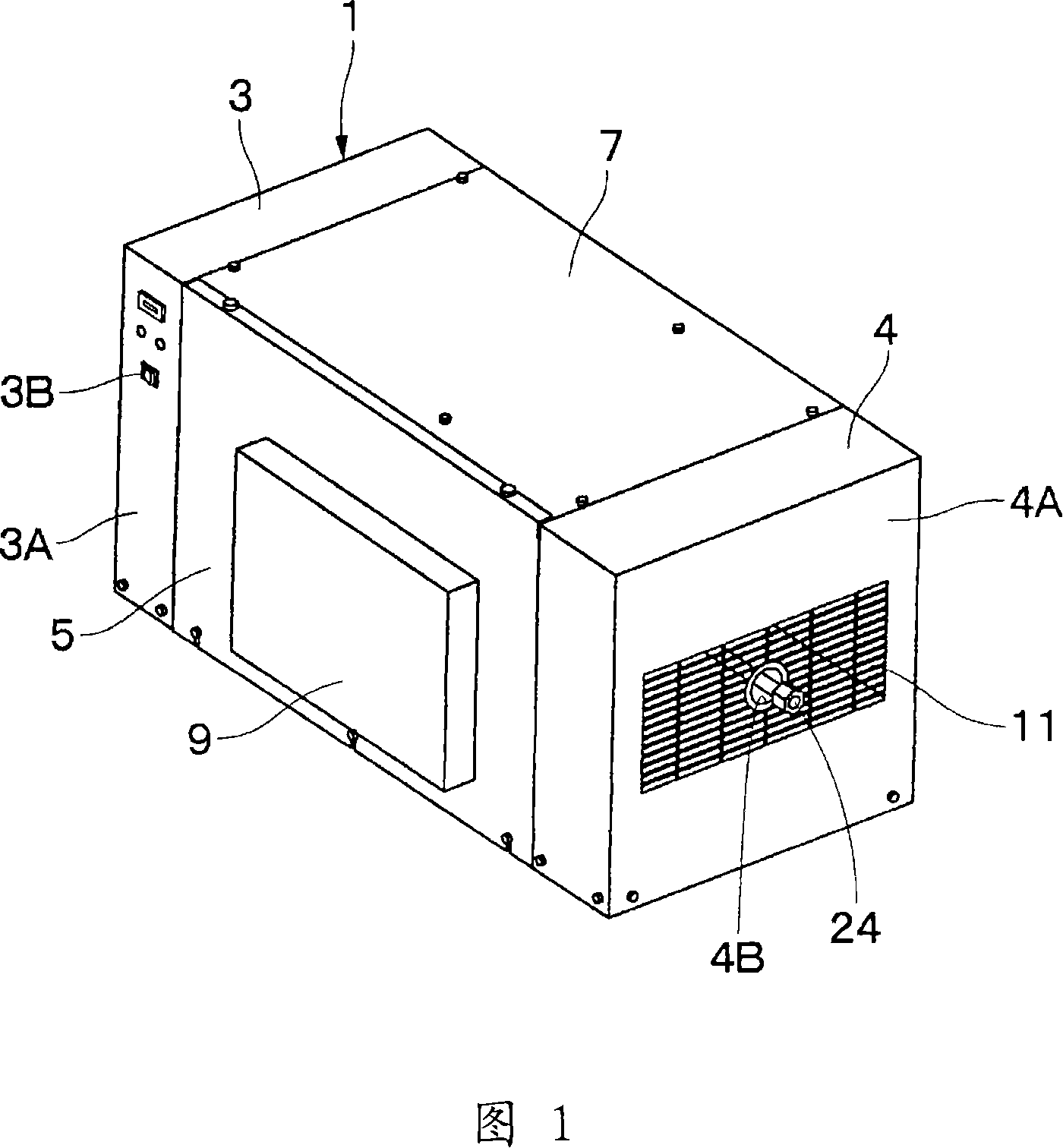

[0087] First, FIGS. 1 to 12 show a first embodiment of the present invention. In FIG. 1 , 1 denotes a package constituting the exterior of the packaged compressor. The package 1 is formed, for example, as a substantially cube-shaped box surrounded by a plurality of steel plates and the like, and has a soundproof structure. Moreover, as shown in FIGS. 1 to 4 , the package 1 is roughly composed of a base 2 on which a compressor main body 12 described later is mounted, a left panel 3 erected on the left side of the base 2 , and a right panel 3 erected on the right side of the base 2 . The panel 4, the front panel 5 arranged at the front between the left panel 3 and the right panel, the rear panel 6 and the top panel 7 integrally provided across the top surface from the back between the left panel 3 and the right panel 4 const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com