Real time monitoring and information management system of coal-firing units gas desulfurization

An information management system and real-time monitoring technology, applied to the separation of dispersed particles, chemical instruments and methods, lighting and heating equipment, etc., can solve problems such as reluctance of desulfurization transformation of power plants, low-price bidding, large project investment, and system not connected to the Internet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

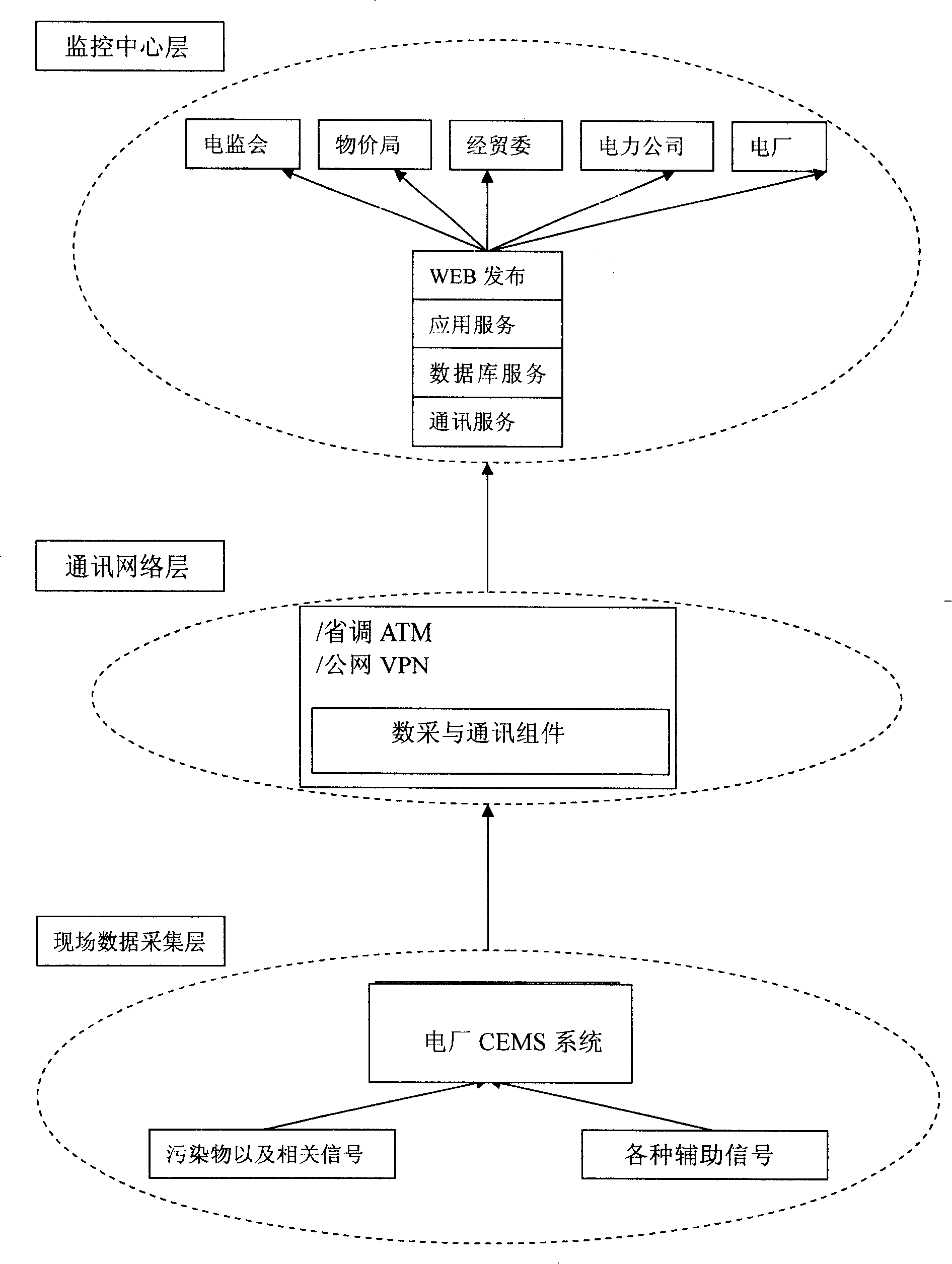

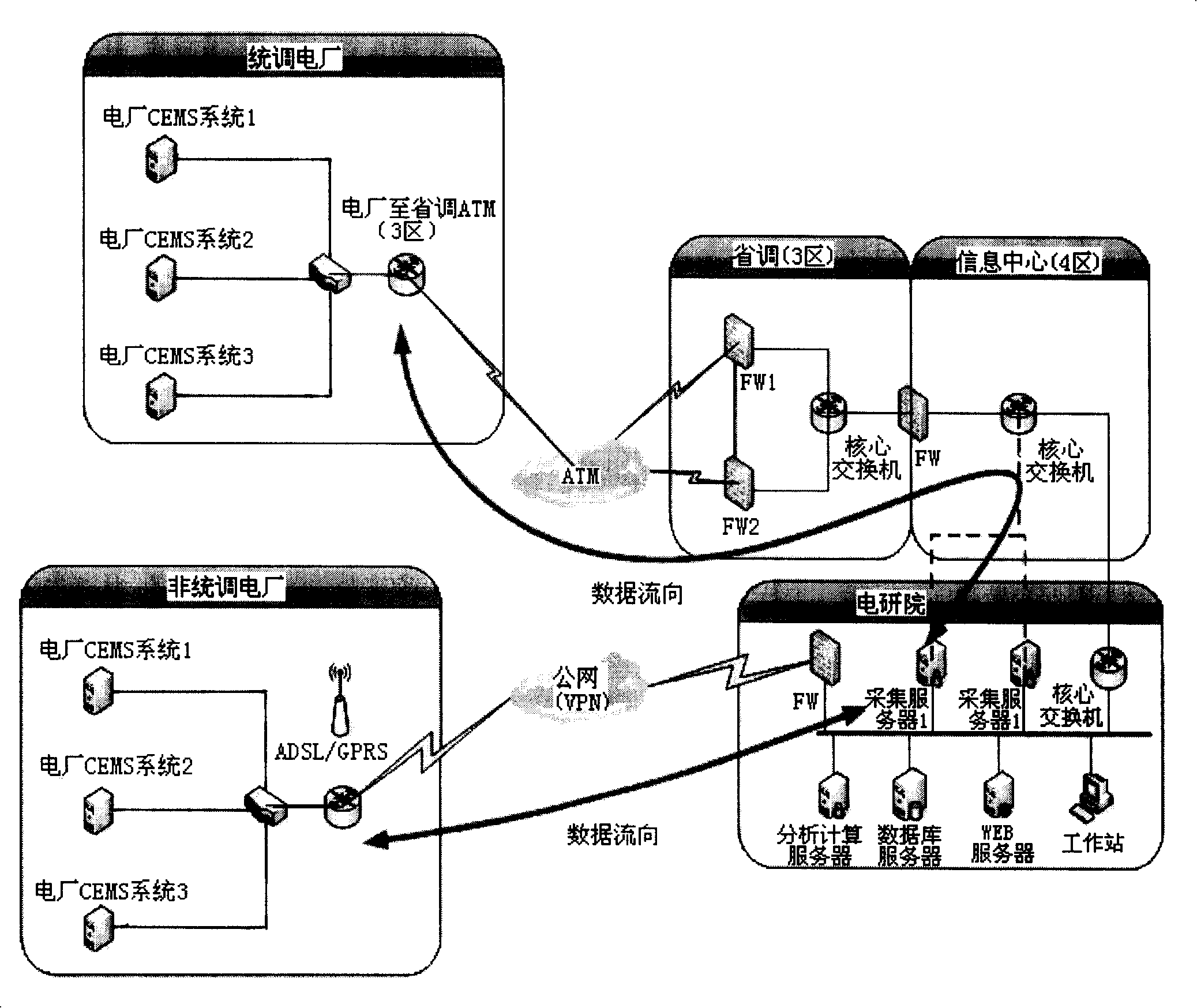

[0028] figure 1 It is a system logic structure diagram of the present invention; figure 2 It is the system physical network topology diagram of the present invention. As shown in the figure, the coal-fired unit flue gas desulfurization real-time monitoring and information management system of the present invention includes three layers: on-site data collection layer, communication network layer and monitoring center layer.

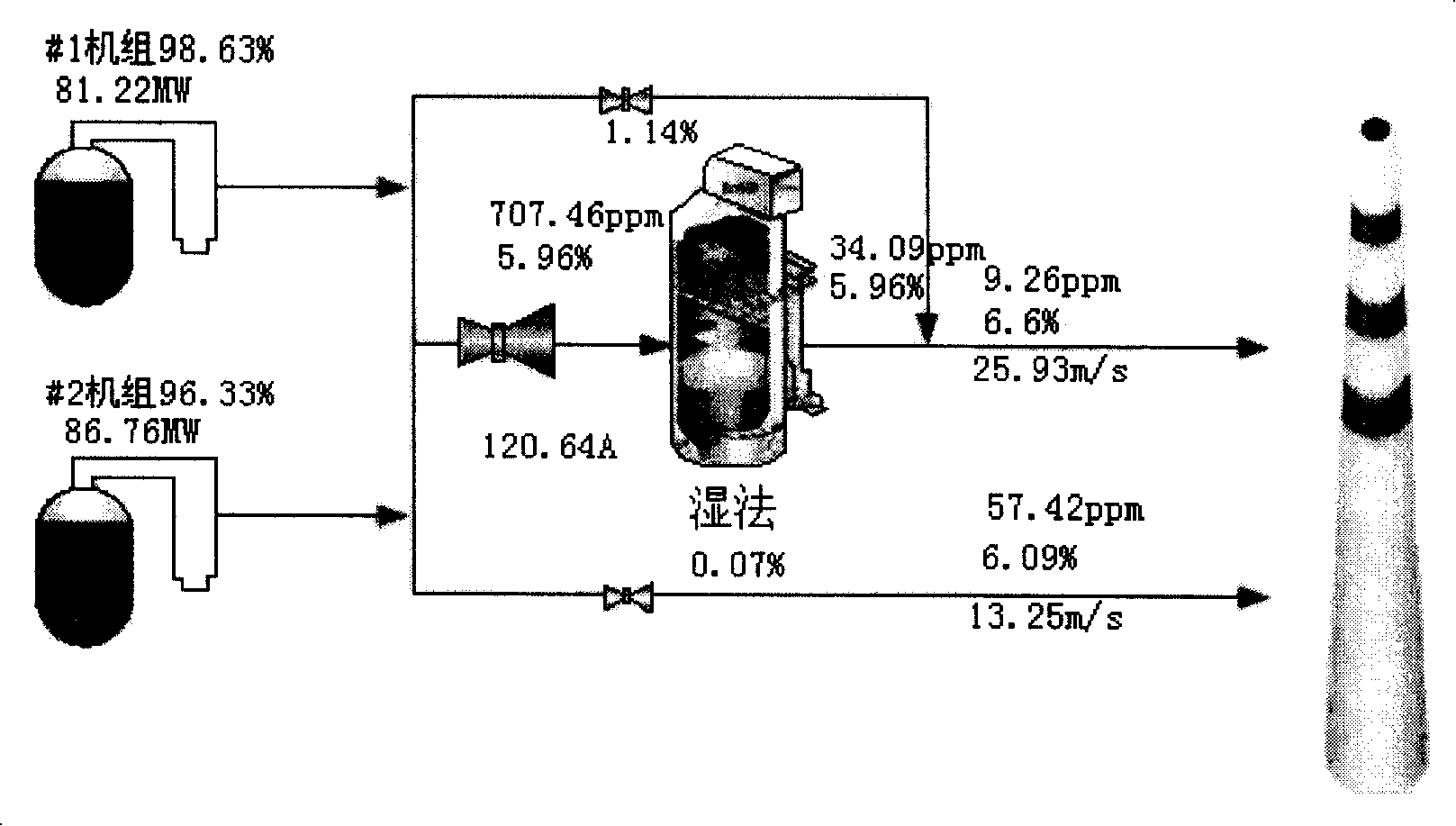

[0029] As the most basic part of the system, the on-site data acquisition layer is installed on the site of each enterprise's monitoring point, which includes various sensors, on-site analysis instruments, data acquisition cards, communication equipment, industrial control computers, and guarantees that these equipment can work safely and reliably. necessary facilities. The CEMS system extracts and filters the flue gas from the flue through the sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com