Molding method and apparatus for making resin molded article

A technology of resin molding and molding method, which is applied in the fields of resin molding and foamed resin molding, and can solve problems such as no clear instructions on the beginning and end of foaming, decreased strength and rigidity of molded products, and enlarged foam area, etc., to achieve The product size and thickness are stabilized, the copying performance is excellent, and the effect of uniformity is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

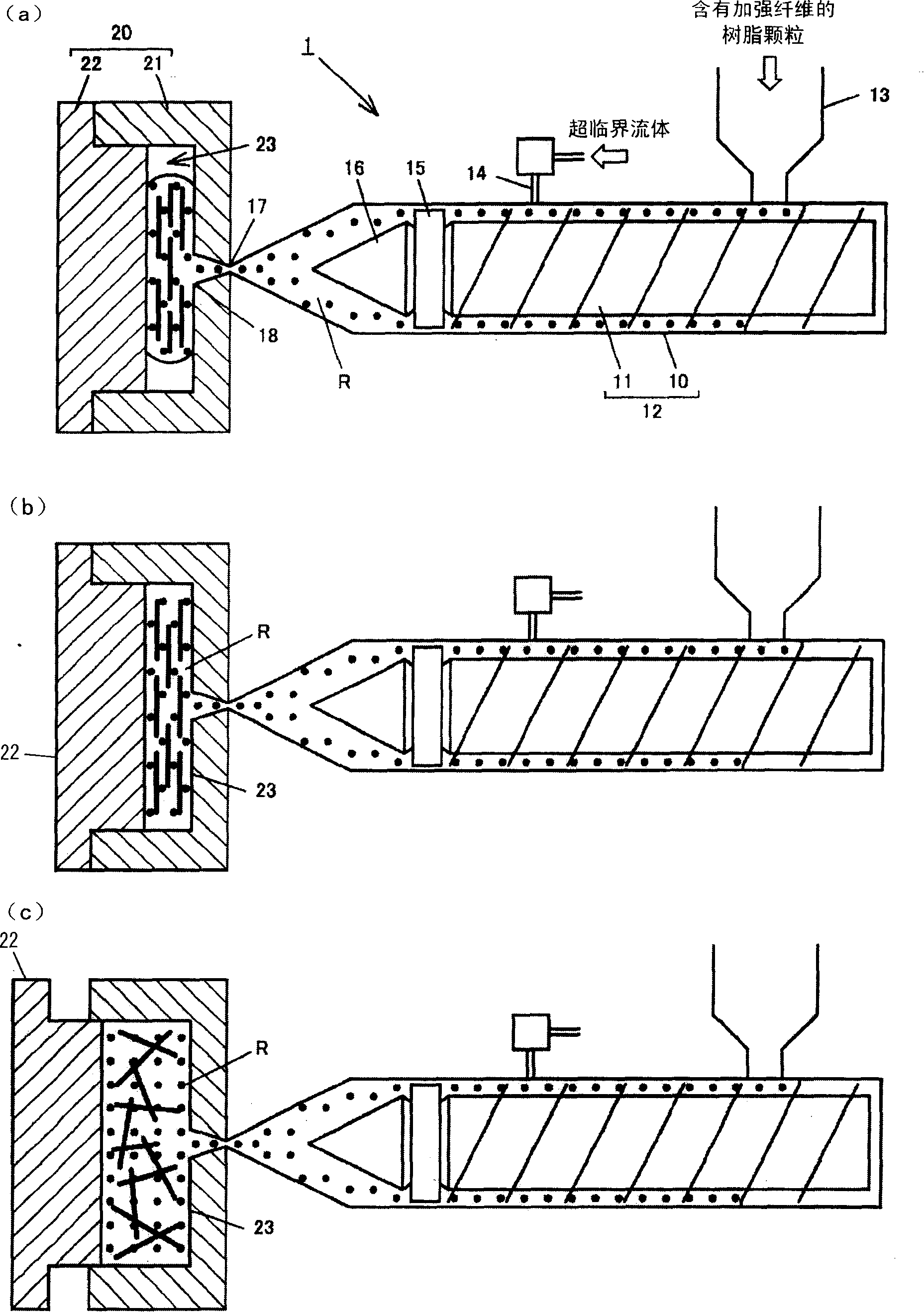

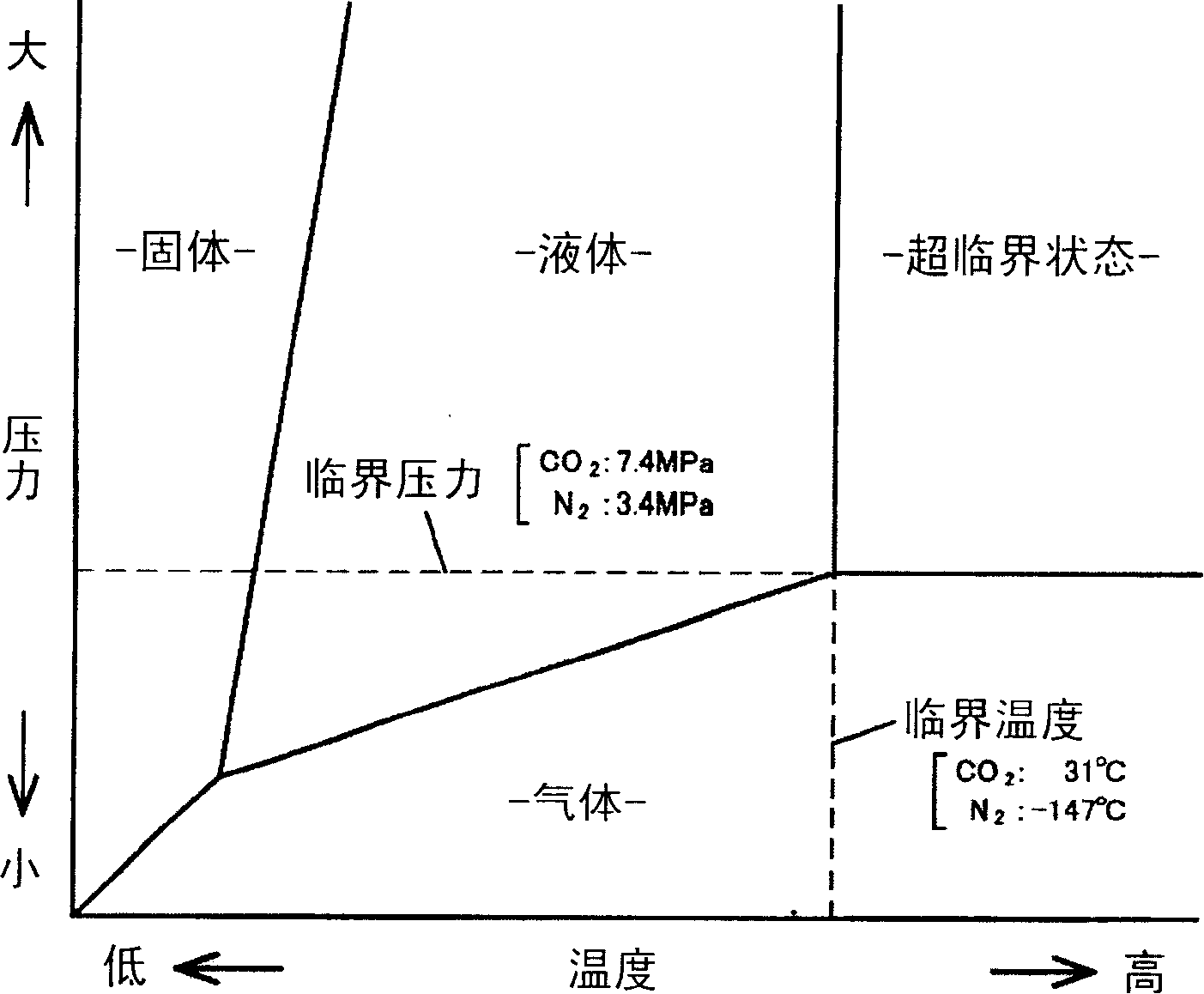

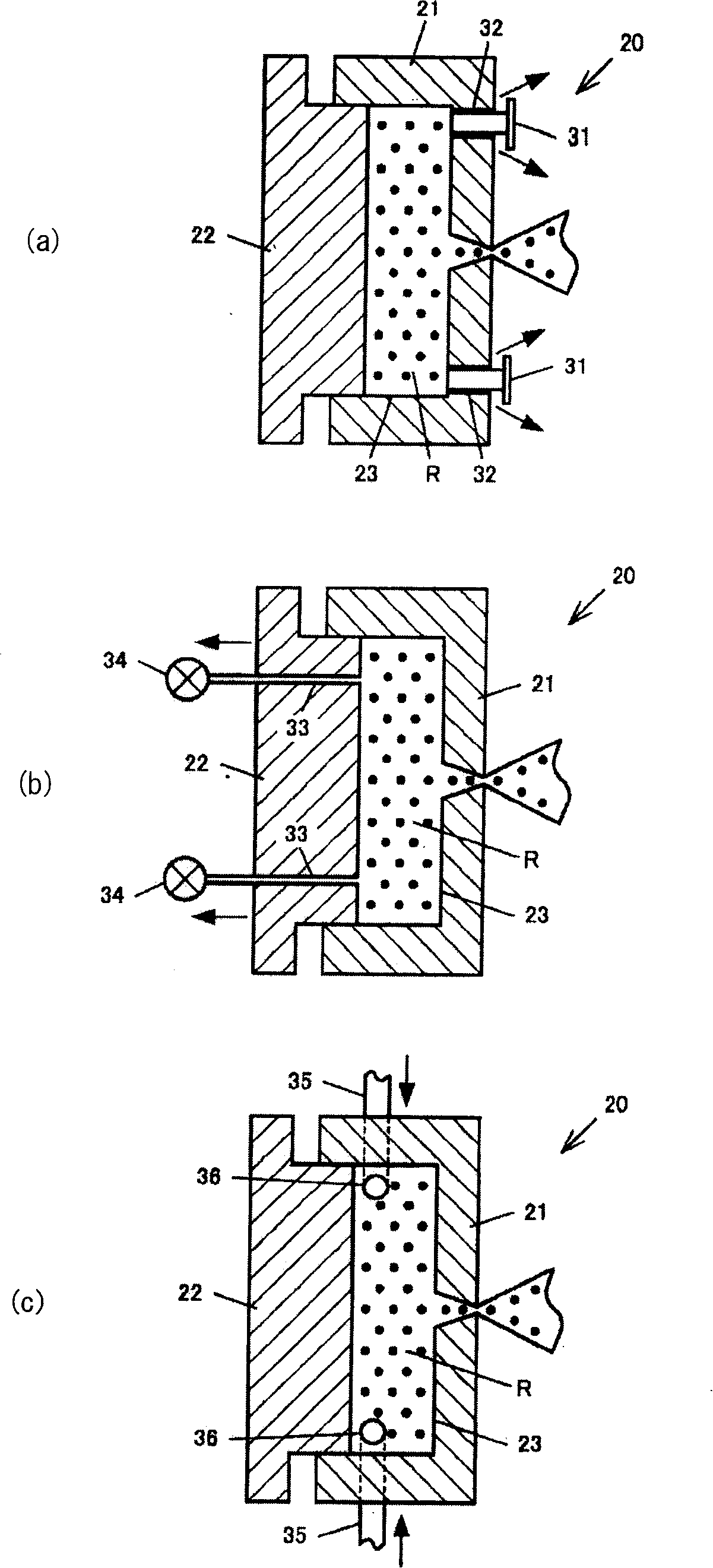

[0035] figure 1 It is an overall schematic diagram schematically showing the structure and operation of the molding apparatus 1 according to the present embodiment. The molding device 1 includes a screw feeder 12 (corresponding to the injection device of the present invention) including a laterally long outer cylinder (cylinder) 10 and a screw 11 and the like. In the vicinity of the start end of the screw feeder 12, a feed hopper 13 is provided through which resin pellets containing reinforcing fibers for reinforcing the resin molded product are fed, and near the terminal end of the screw feeder 12 is connected There is a supply pipe 14 for supplying supercritical fluid. The upstream side of the supply pipe 14 is connected to a gas cylinder of an inert gas such as nitrogen (N 2 ) and carbon dioxide (CO 2 ) through a supercritical fluid generation and supply device (not shown). The screw 11 includes a check ring 15 and a tapered head 16 provided at the front end thereof. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com