Method for manufacturing tarpaulin

A manufacturing method and canvas technology, which are applied in textiles and papermaking, devices for coating liquid on surfaces, surface pretreatment, etc., can solve the problems of increased management costs, space occupied by creels and labor costs, and reduce labor costs and management costs. The effect of reducing the incidence of unqualified products and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

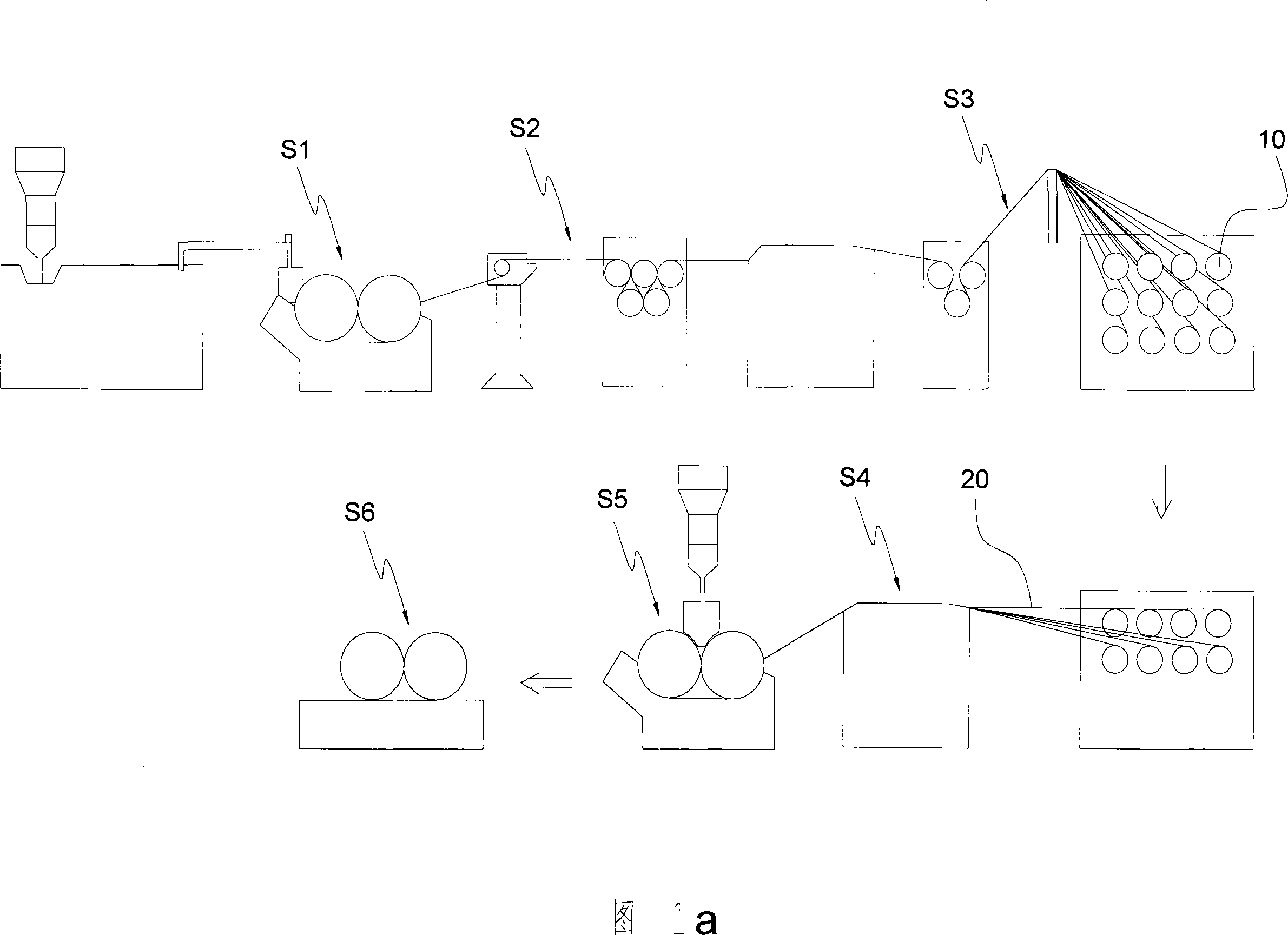

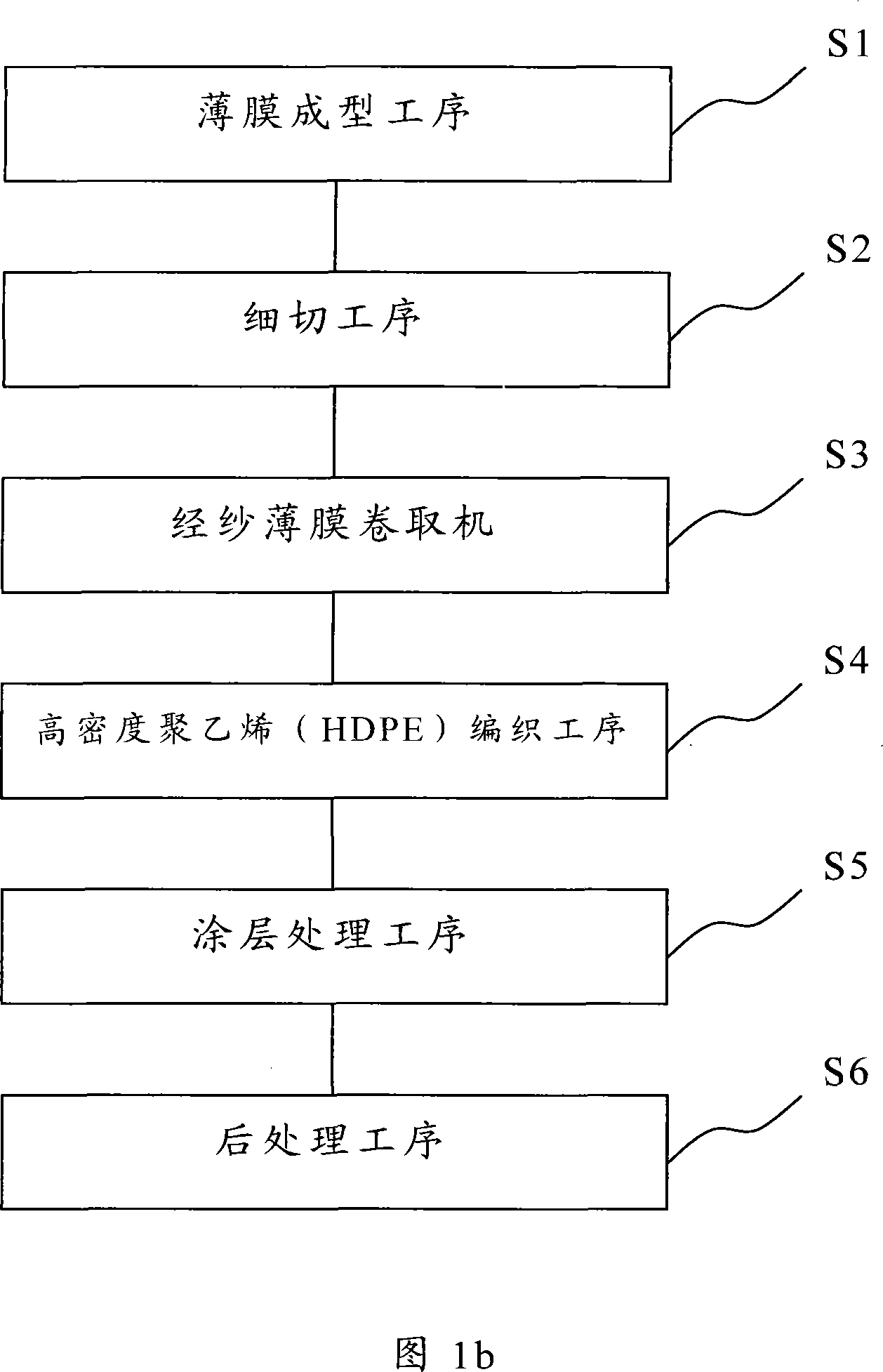

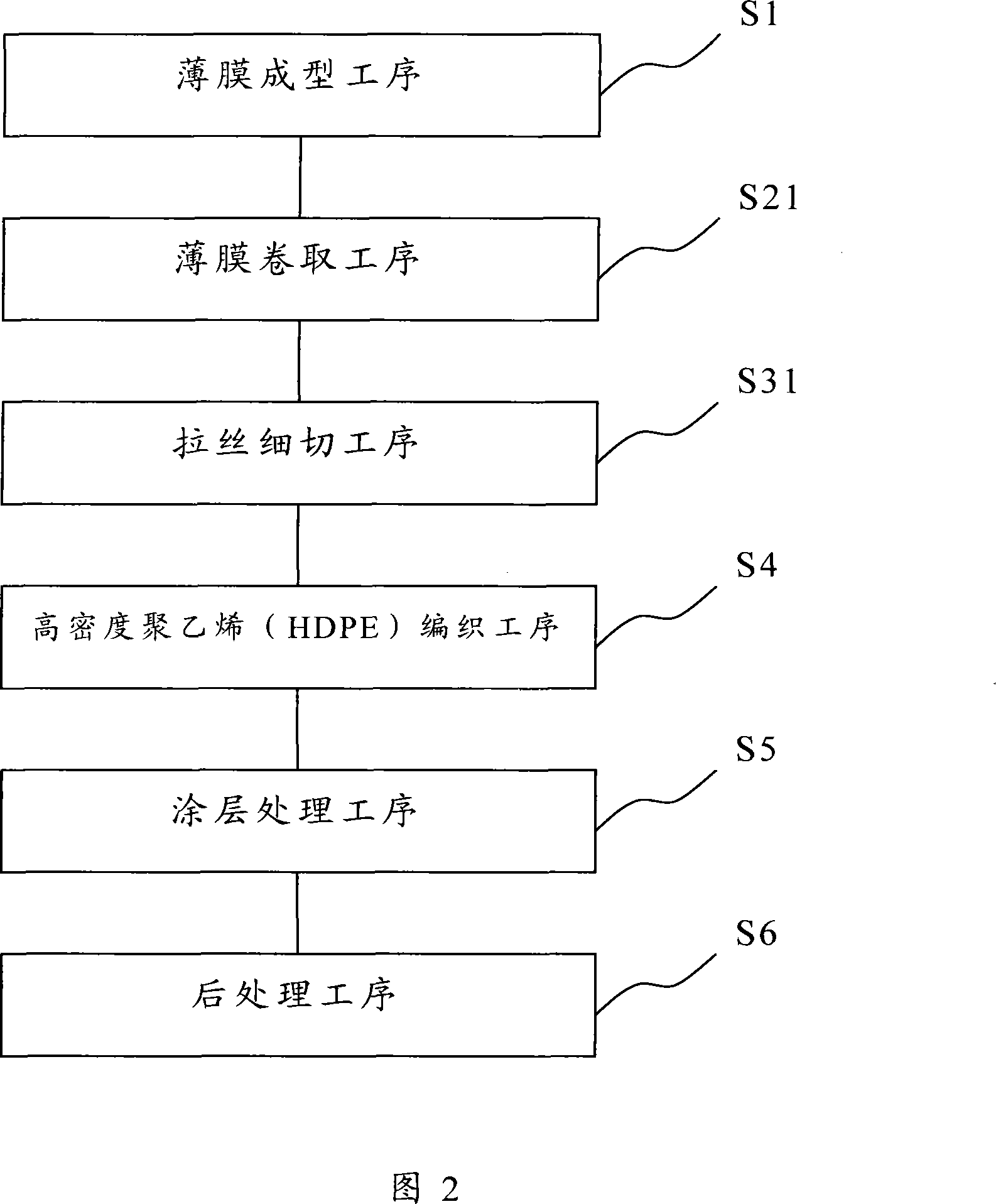

[0033] See Figure 2,

[0034] Film forming process S1 of high density polyethylene melt forming film;

[0035] By stretching and shrinking the formed film, the tensile strength is increased, and the film winding process S21 is wound on the reel;

[0036] The wire-drawing and fine-cutting process S31 in which the warp film wound on the reel is drawn and finely cut from the reel;

[0037] The weaving process S4 of the HDPE woven by the finely cut warp and weft silk films;

[0038] The coating process S5 of coating low-density polyethylene (LDPE) on the high-density polyethylene (HDPE) film fabric layer woven by weft and warp yarns;

[0039] Dry the low-density polyethylene (LDPE) coated canvas with hot air to complete the post-processing step S6 of weaving.

[0040] In particular, in the film winding process S21, the conventional fine cutting process S2 of slit film is eliminated, and the film is directly wound up on the roll. At this time, since the wound warp yarn film is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com