High-speed diesel electronic control transverse currents continuousvariable mechanical installation

A technology of electronic control and mechanical devices, which is applied in engine control, mechanical equipment, machines/engines, etc. It can solve the problems of high combustion pressure and temperature, increased NOX emissions, diesel engine power, and economical efficiency. , to improve fuel economy and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

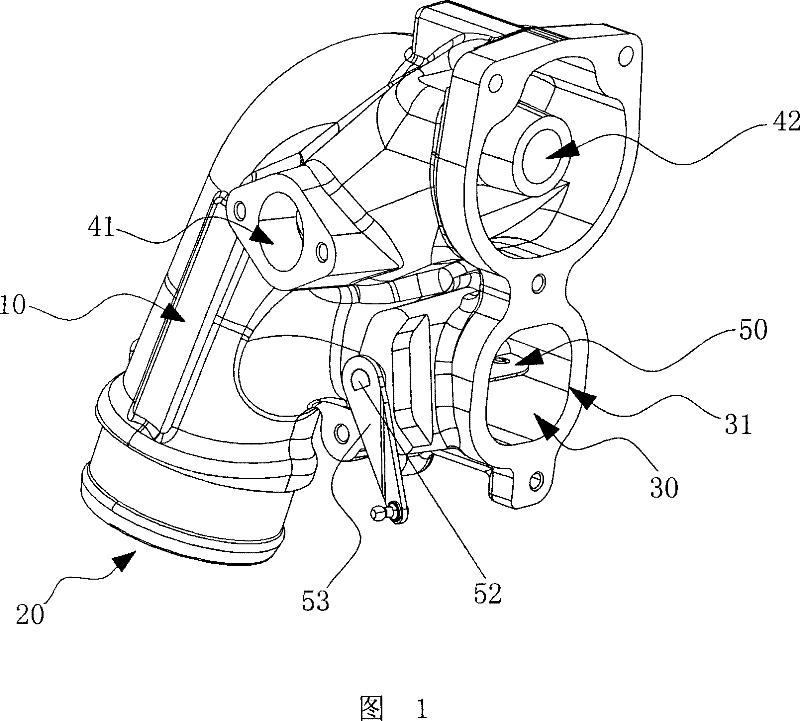

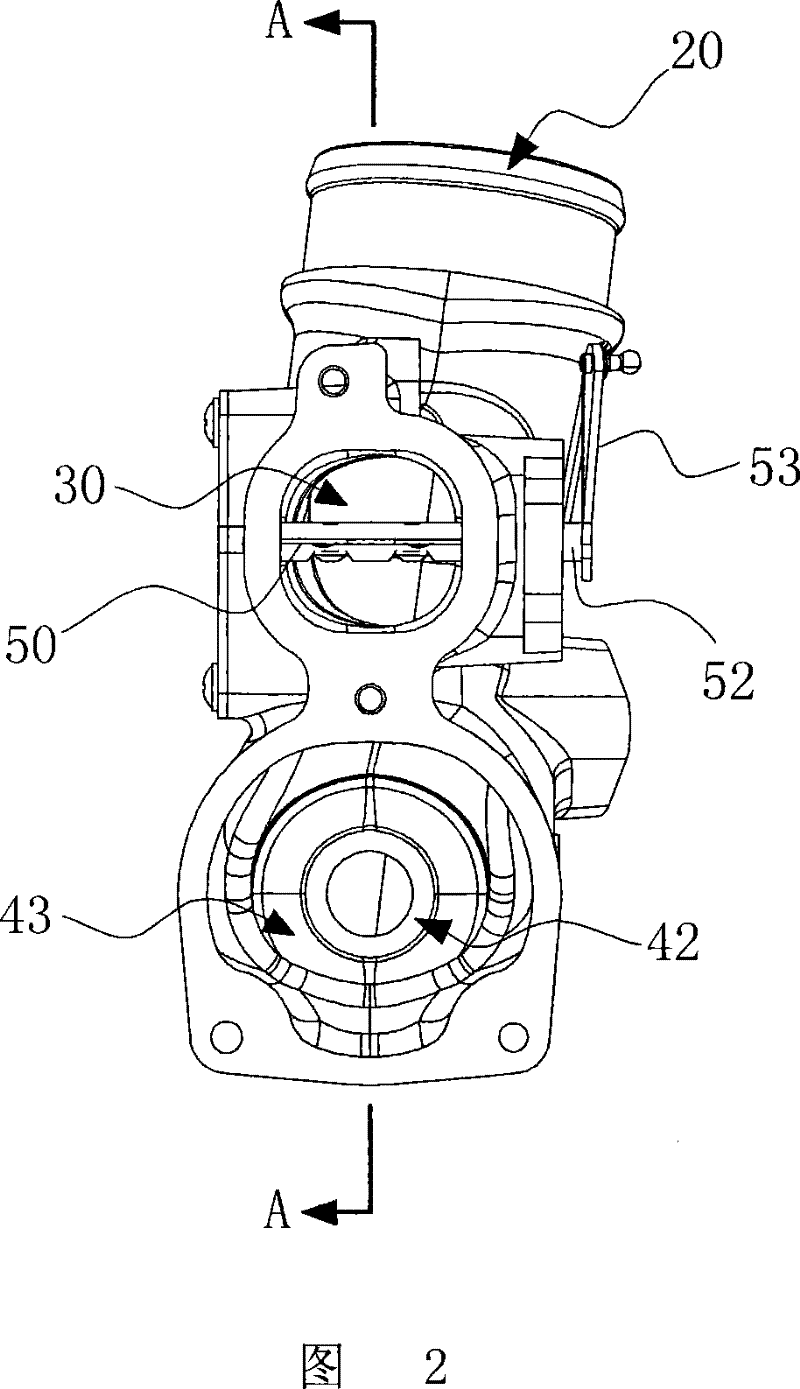

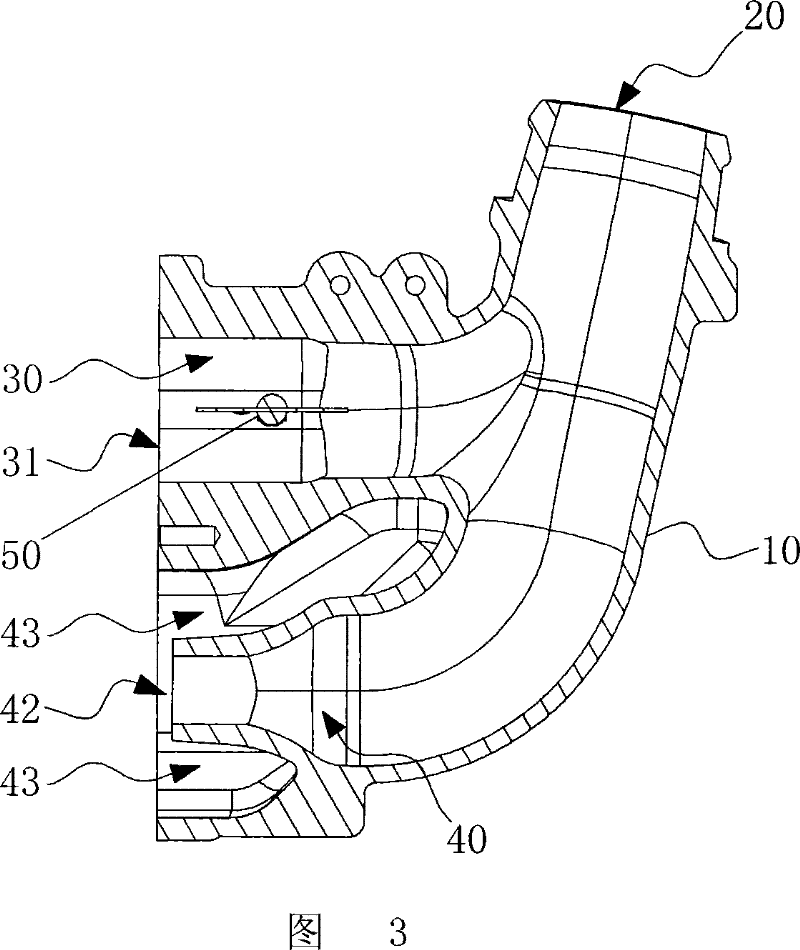

[0011] Such as figure 1 , 2 As shown in , 3, the high-speed diesel engine electronic control vortex continuously variable mechanical device includes a housing 10 on which an air inlet 20 is arranged, and the air inlet 20 is externally connected to an air intake hose. Inside the housing 10, the air inlet There are two intake passages at the rear end of 20, one passage is the intake swirl continuously variable passage 30, and the other passage is the EGR exhaust gas recirculation passage 40, and the passage of the intake swirl continuously variable passage 30 is provided with A throttle valve 50.

[0012] The passage opening 31 of the intake swirl continuously variable passage 30 and the two passage openings 41 and 42 of the EGR exhaust gas recirculation passage 40 extend to the surface of the housing 10, and the EGR exhaust gas recirculation passage 40 is a venturi In the inner pipe, there is an EGR pre-mixing chamber 43 around the small-diameter nozzle 42 of the EGR exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com