Heat radiator for liquid cooling type heat radiating device

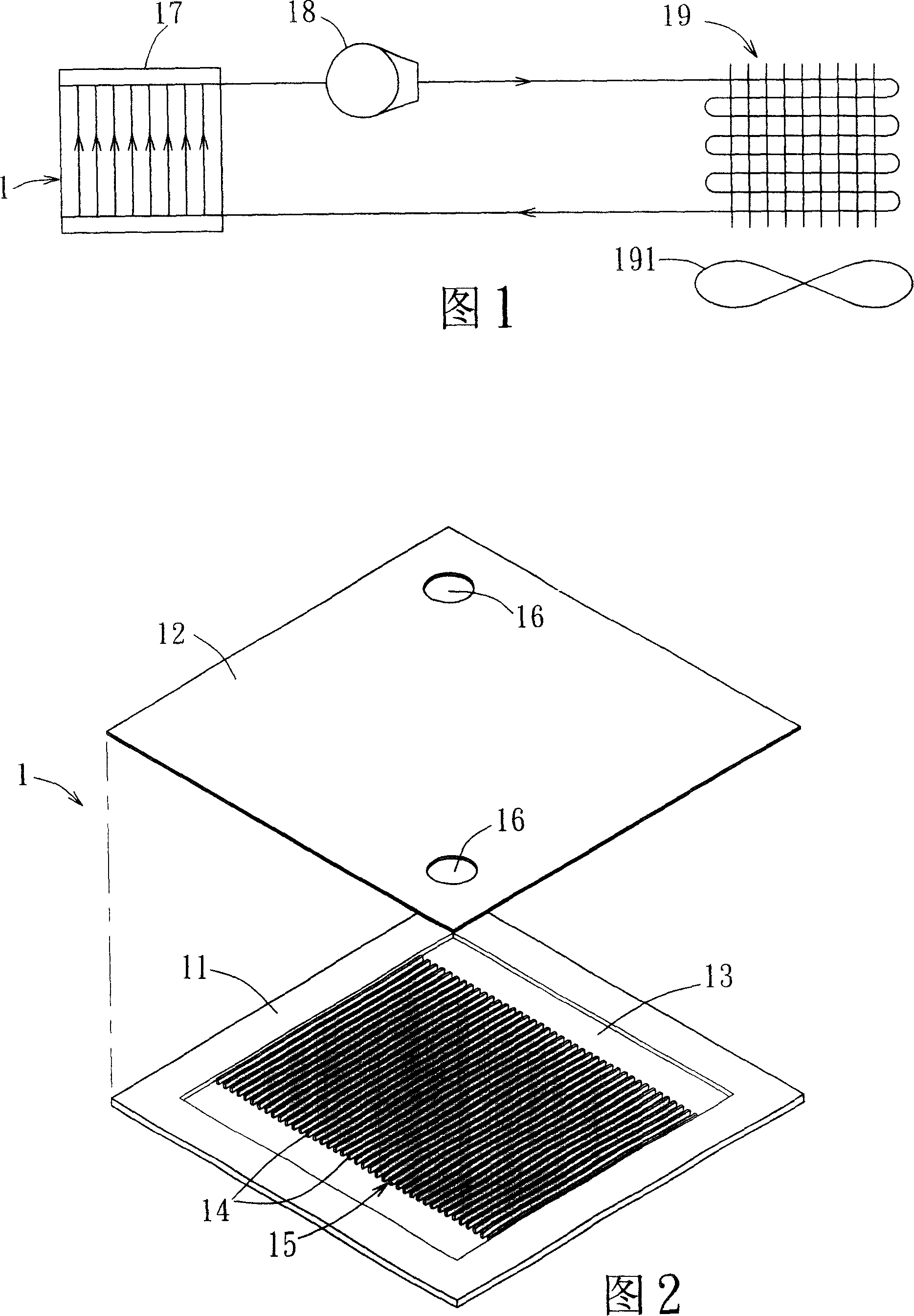

A technology of heat dissipation device and liquid cooling, applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, it can solve the problems of uneven flow velocity distribution, fluid stagnation, affecting the heat soaking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of four preferred embodiments with reference to the drawings.

[0026] For convenience of description, in the following embodiments, the same or similar elements are denoted by the same reference numerals.

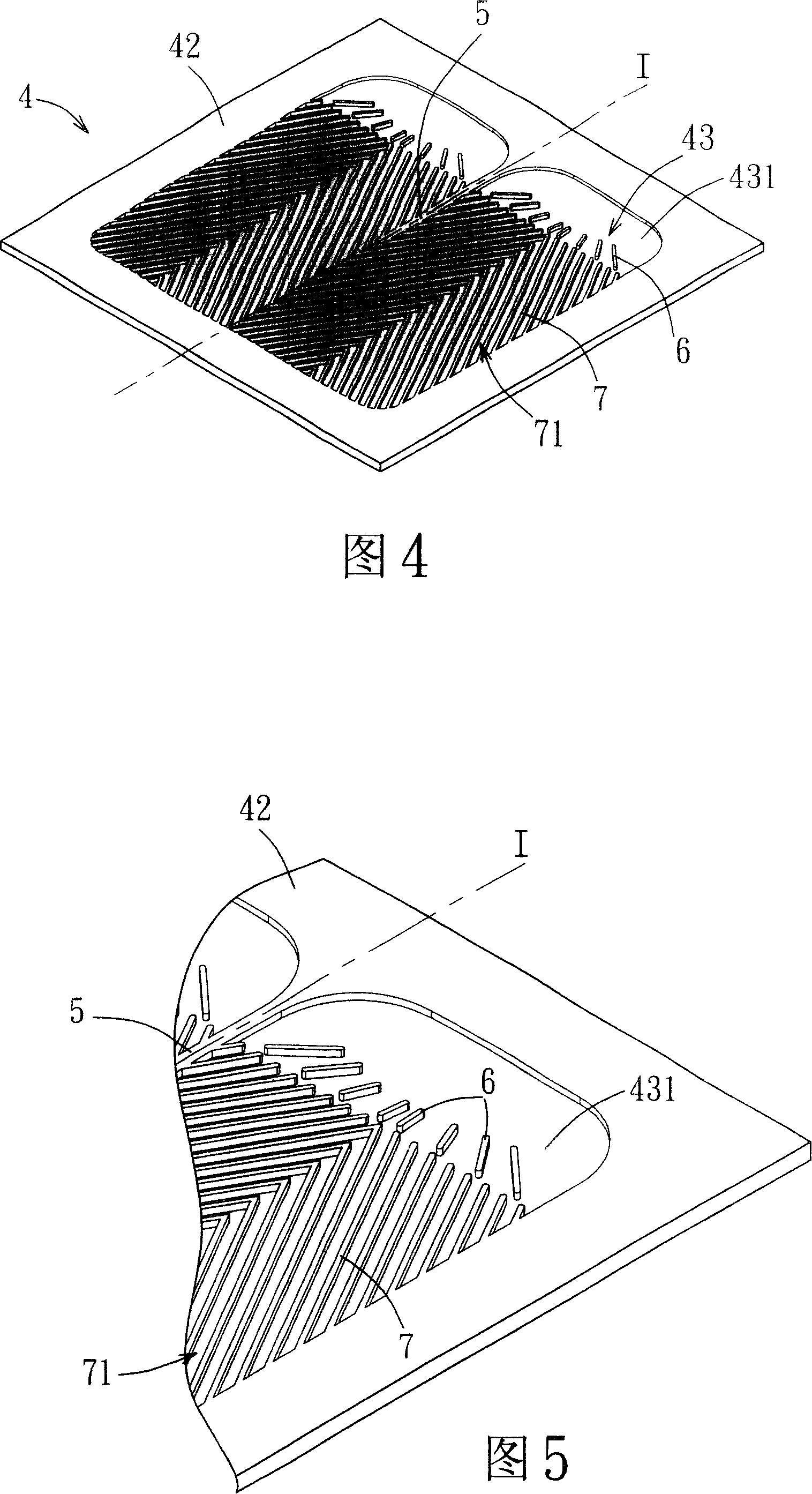

[0027] See Figure 4 to Figure 7 , The first preferred embodiment of the heat sink of the liquid-cooled heat sink of the present invention includes a housing unit 4, a partition plate 5, and a plurality of interfering elements. The housing unit 4 is made of heat-conducting material and forms an accommodating space 43. The housing unit 4 has an upper plate 41 and a lower plate 42 matched with the upper plate 41. The upper plate 41 Two water outlets 411 that communicate with the accommodating space 43 are formed on the top; the partition plate 5 is located on the center line L1 of the accommodating space 43, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com