Form component forming mould

A formwork component and forming mold technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of inconvenient demoulding and easy damage of thin-walled boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

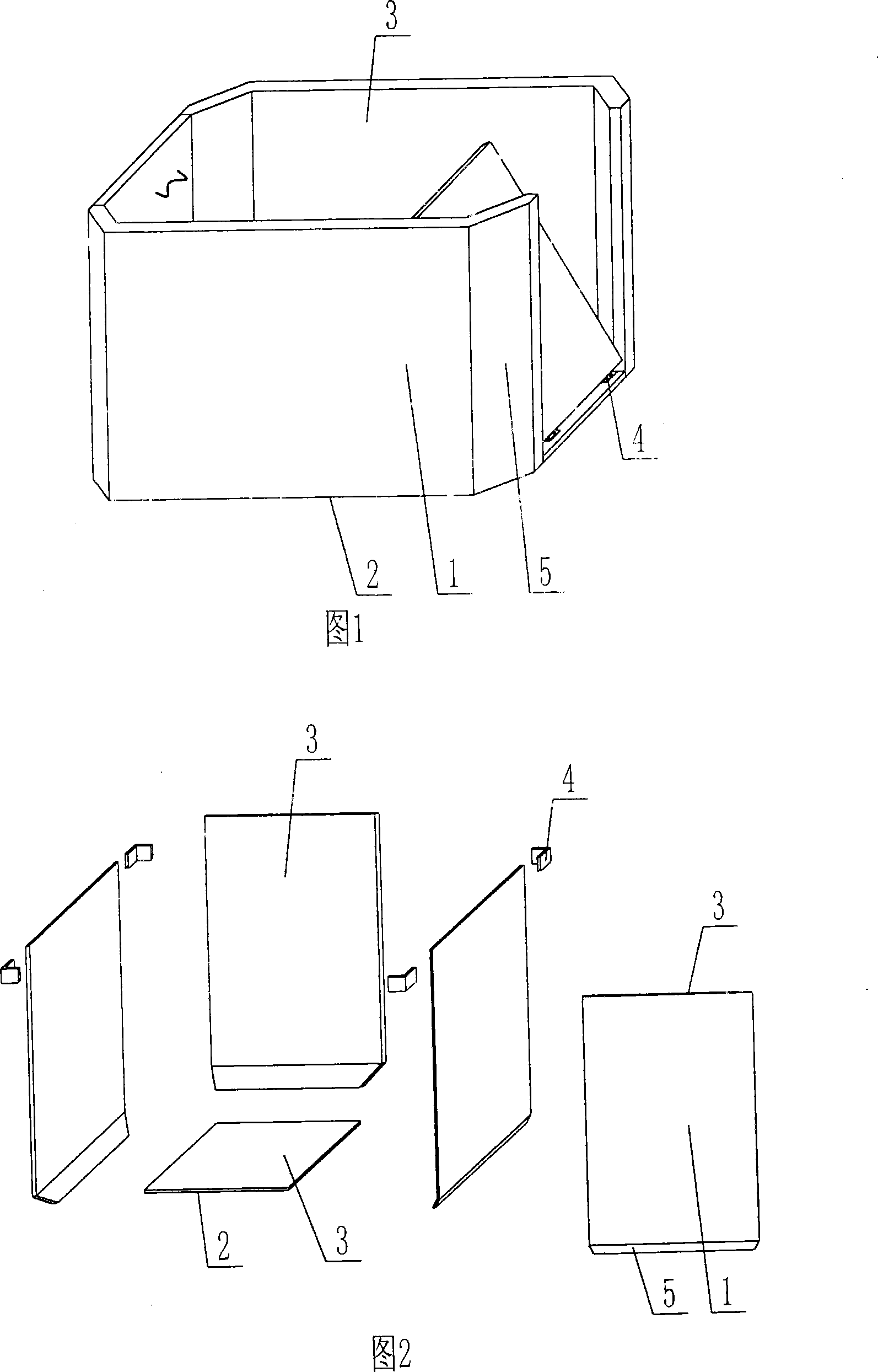

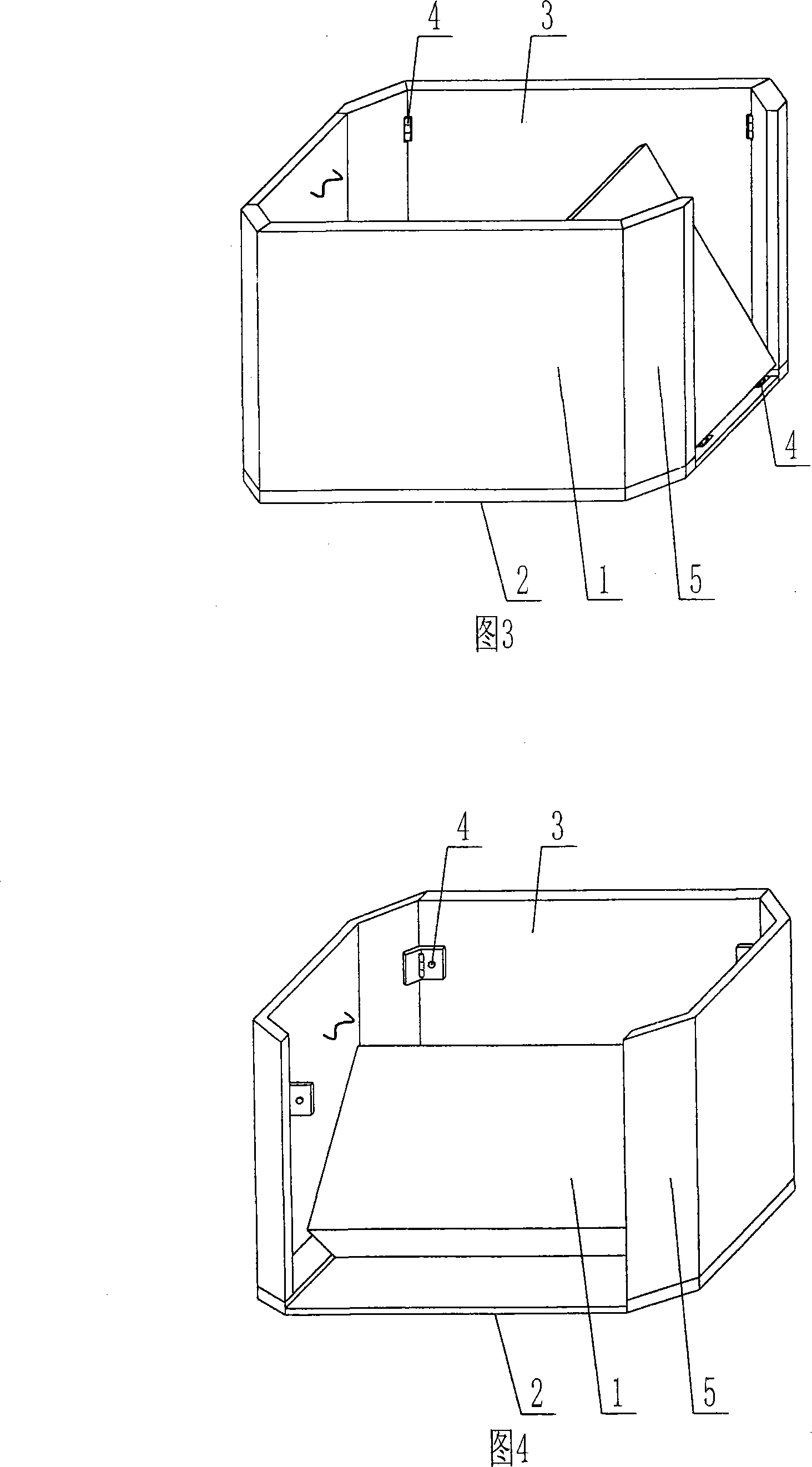

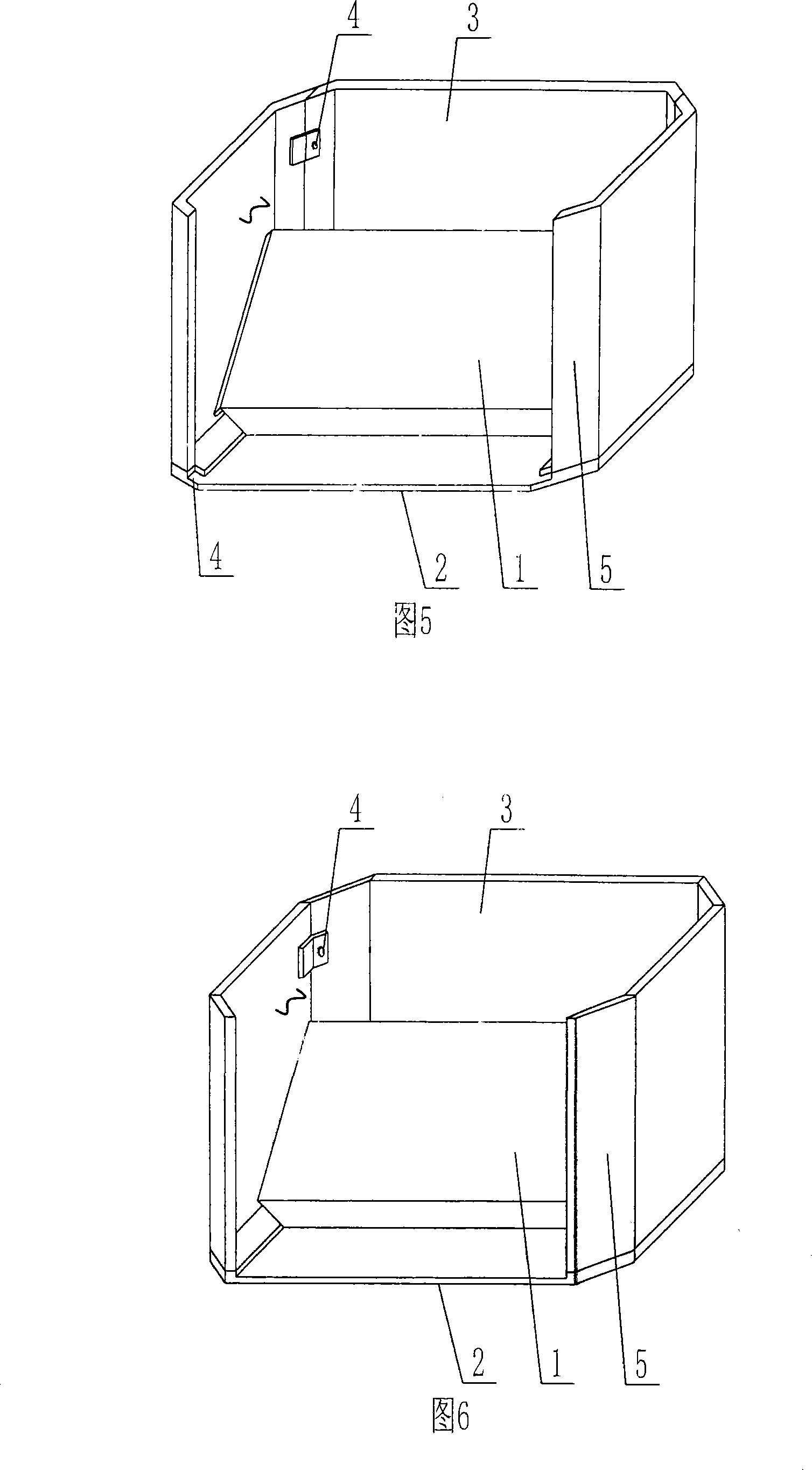

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0064] As shown in the accompanying drawings, the present invention includes a side mold surface 1 and a lower mold surface 2, and the side mold surface 1 and the lower mold surface 2 form a male mold, and is characterized in that the side mold surface 1 and the lower mold surface of the male mold 2 consists of a template 3, the male mold is assembled by a lower mold surface template and four side mold surface templates, a splicing device 4 is arranged on the combined template 3, and the corner portion of the mold surface is set as a chamfered surface 5. In each accompanying drawing, 1 is a side mold surface, 2 is a lower mold surface, 3 is a template, 4 is a splicing device, and 5 is a chamfering surface. In the following accompanying drawings, those with the same numbering have the same description. As shown in Figure 1, the side mold surface 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com