Pre-humidifying starching method for yarn

A pre-feeding and sizing technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, spray/jet textile material treatment, etc., can solve the problems of poor wetting and penetrating ability of slurry, yarn strength drop, yarn path Lengthening and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

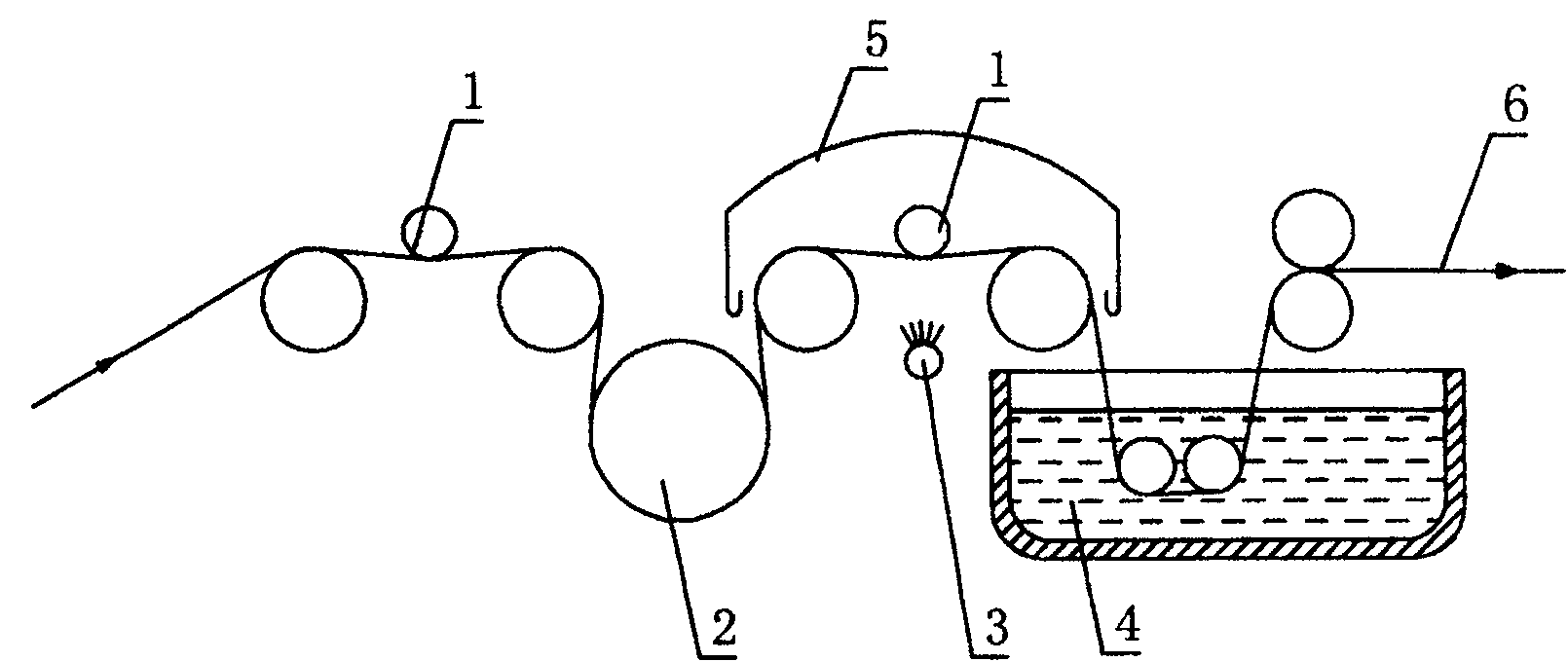

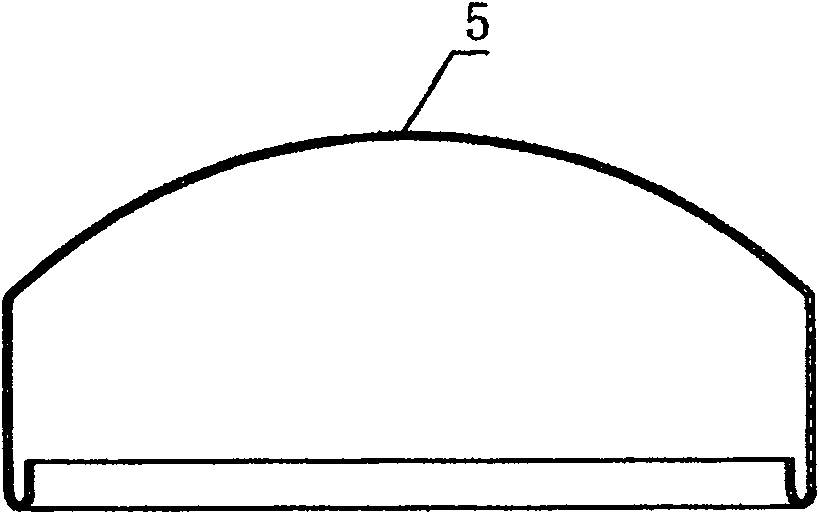

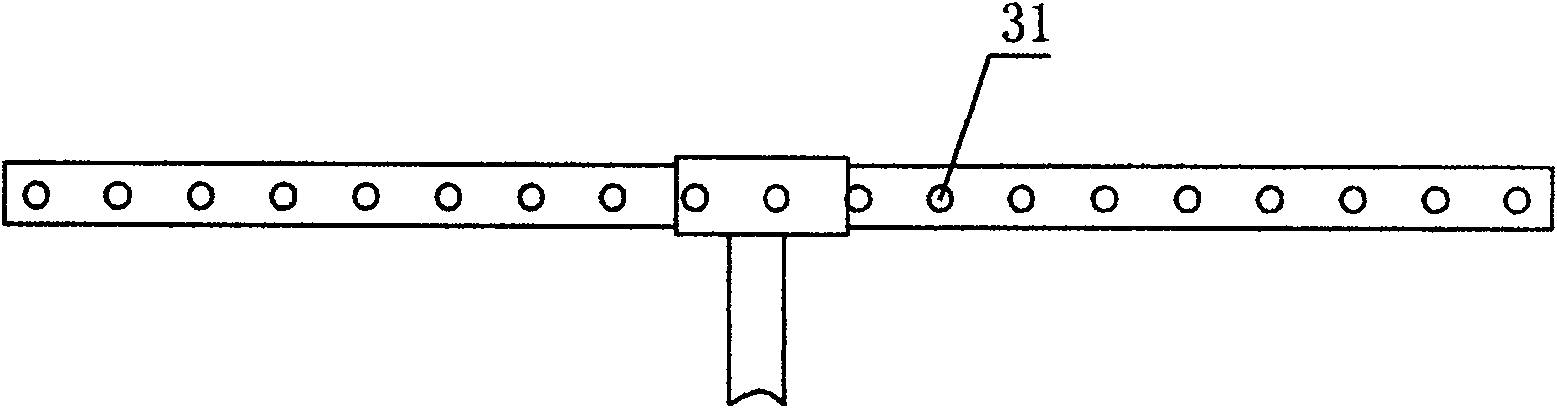

[0015] Such as figure 1 The device that implements the sizing pre-humidification and sizing method of the present invention shown in, on the sizing machine body, yarn 6 such as figure 1 As shown by the middle arrow, it enters the sizing tank 4 through the yarn guide tension compensation device 1, the yarn guide roller 2, and the yarn guide tension compensation device 1 in turn, and then enters the drying device after being sized by the dipping roller and the pressure roller. The steam spray pipe 3 that can spray steam to the yarn in the form of a steam jet flow is provided below the yarn 6 advancing between the roller 2 and the size tank 4, such as image 3 As shown in , the steam injection pipe 3 is provided with several injection holes 31, and the steam injection pipe 3 can be connected with the steam pipeline leading to the slurry tank 4 in actual production, such as at the steam valve leading to the slurry tank 4 steam pipe , add a φ15-30mm inner joint and a tee (the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com