Railway sleeper

A sleeper and track technology, applied in the field of track sleepers, can solve the problem that the attenuation of mechanical vibration is not completely satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

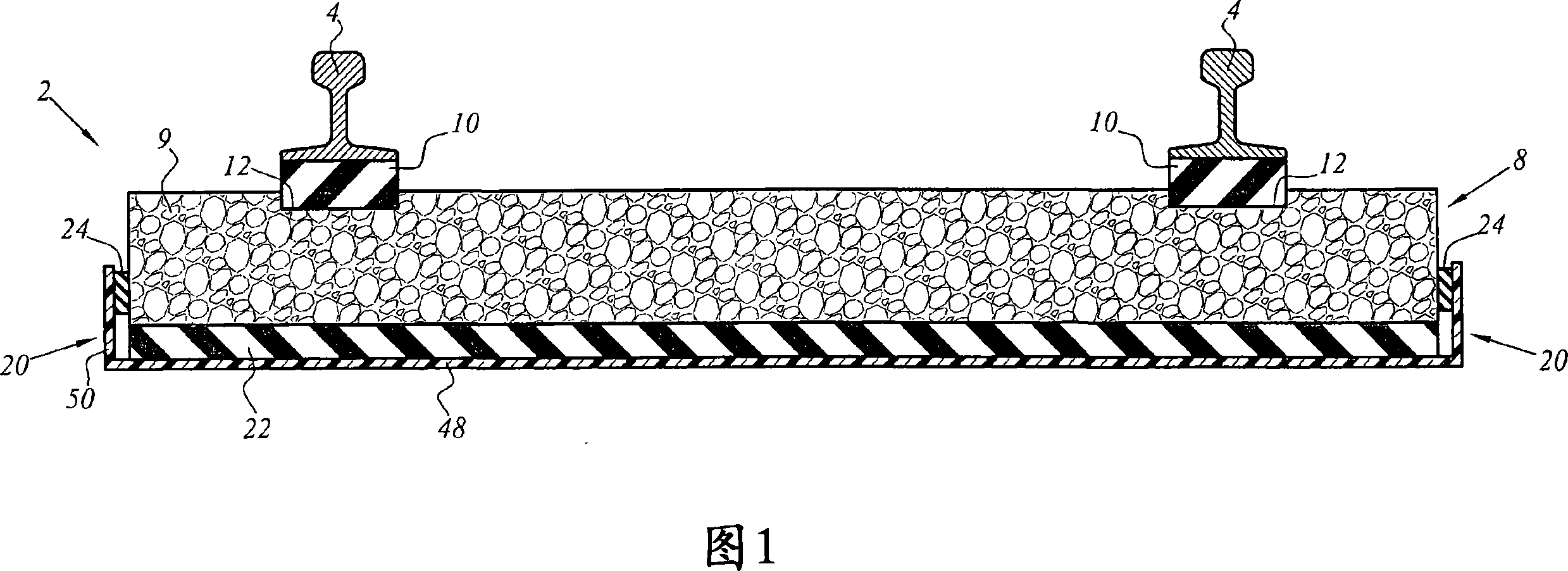

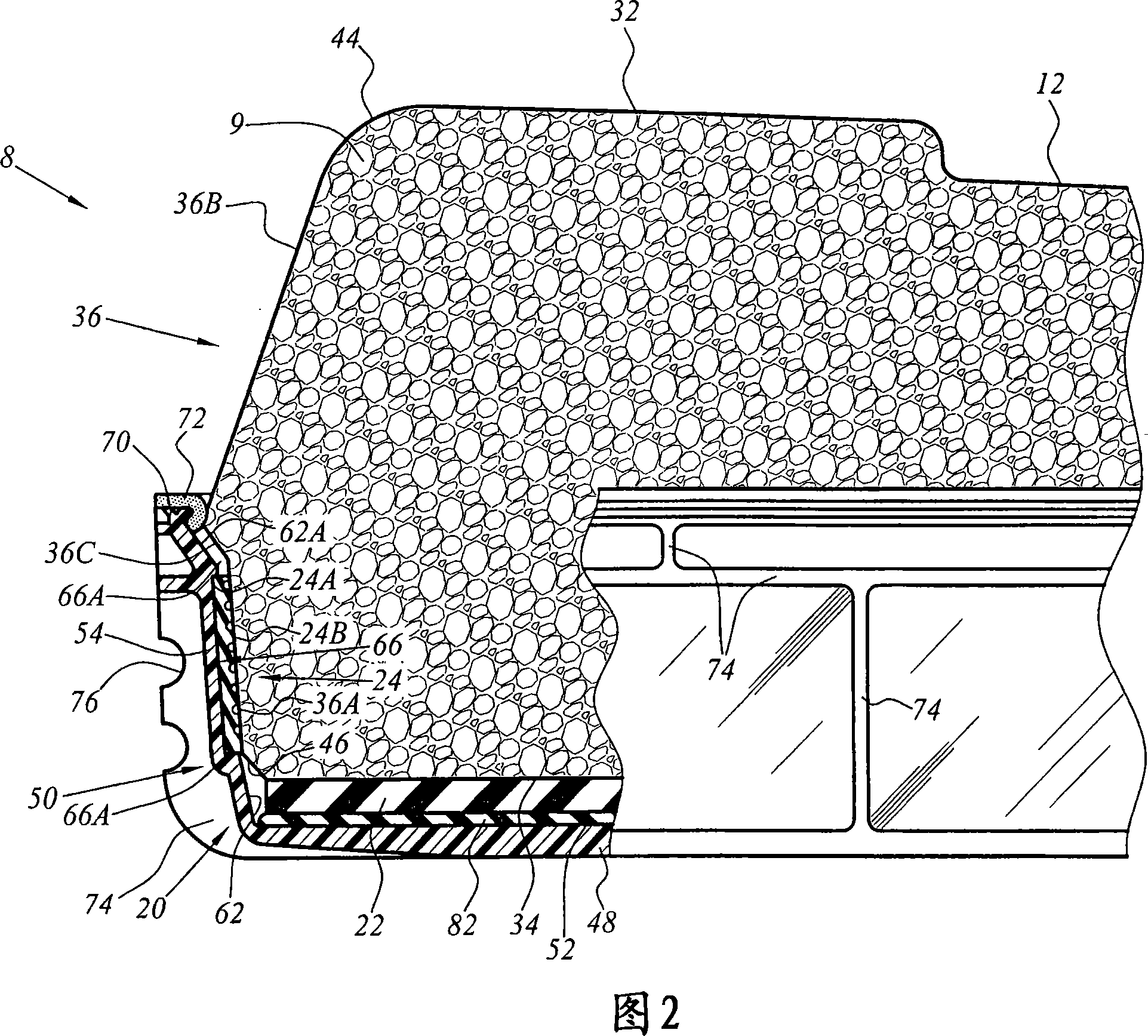

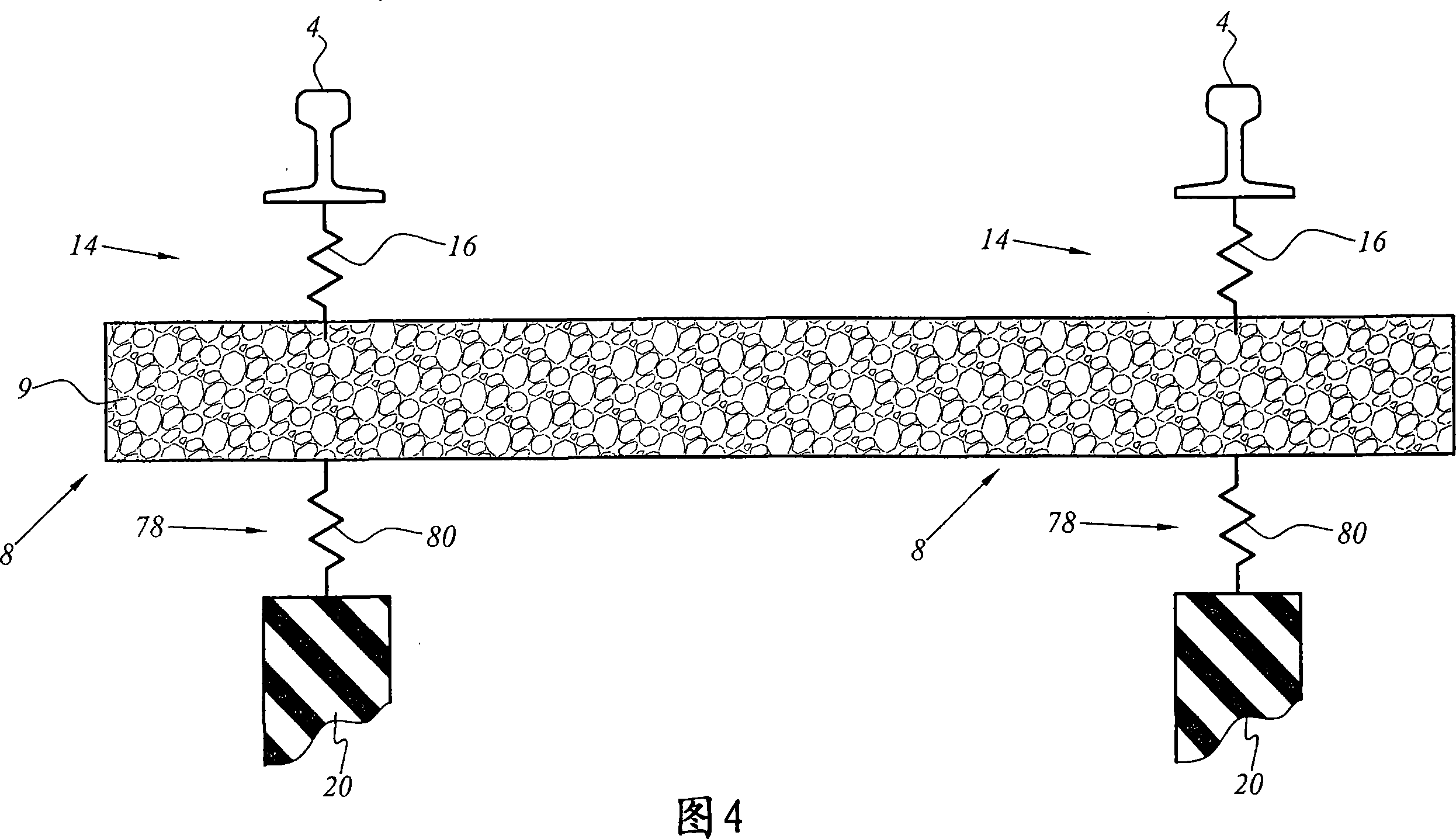

[0030] [30] The track section 2 in the first embodiment of the present invention is schematically shown in FIG. 1 . The track section 2 comprises two longitudinal rails 4 fastened to sleepers 8 . The sleeper 8 comprises a single concrete block 9 and two elastic support elements 10 arranged between each track 4 and the concrete block 9 .

[0031] [31] By convention, the longitudinal rail 4 is determined to be used as a reference for the longitudinal direction.

[0032] [32] The elastic support element 10 is substantially in the form of a cuboid. In the embodiment shown in FIG. 1 , their width is substantially equal to the width of the base of the track 4 and their length is substantially equal to the width of the block 9 .

[0033] [33] The elastic support elements 10 are received in respective grooves 12 in the block 9 . The profile of each groove 12 in the sectional view is substantially rectangular. The width and length of each groove 12 are substantially equal to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com