Embroidery sewing machine and embroidery start position setting method

A starting position, sewing machine technology, applied in the direction of program-controlled sewing machines, embroidery machines, sewing machines, etc., can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the drawings.

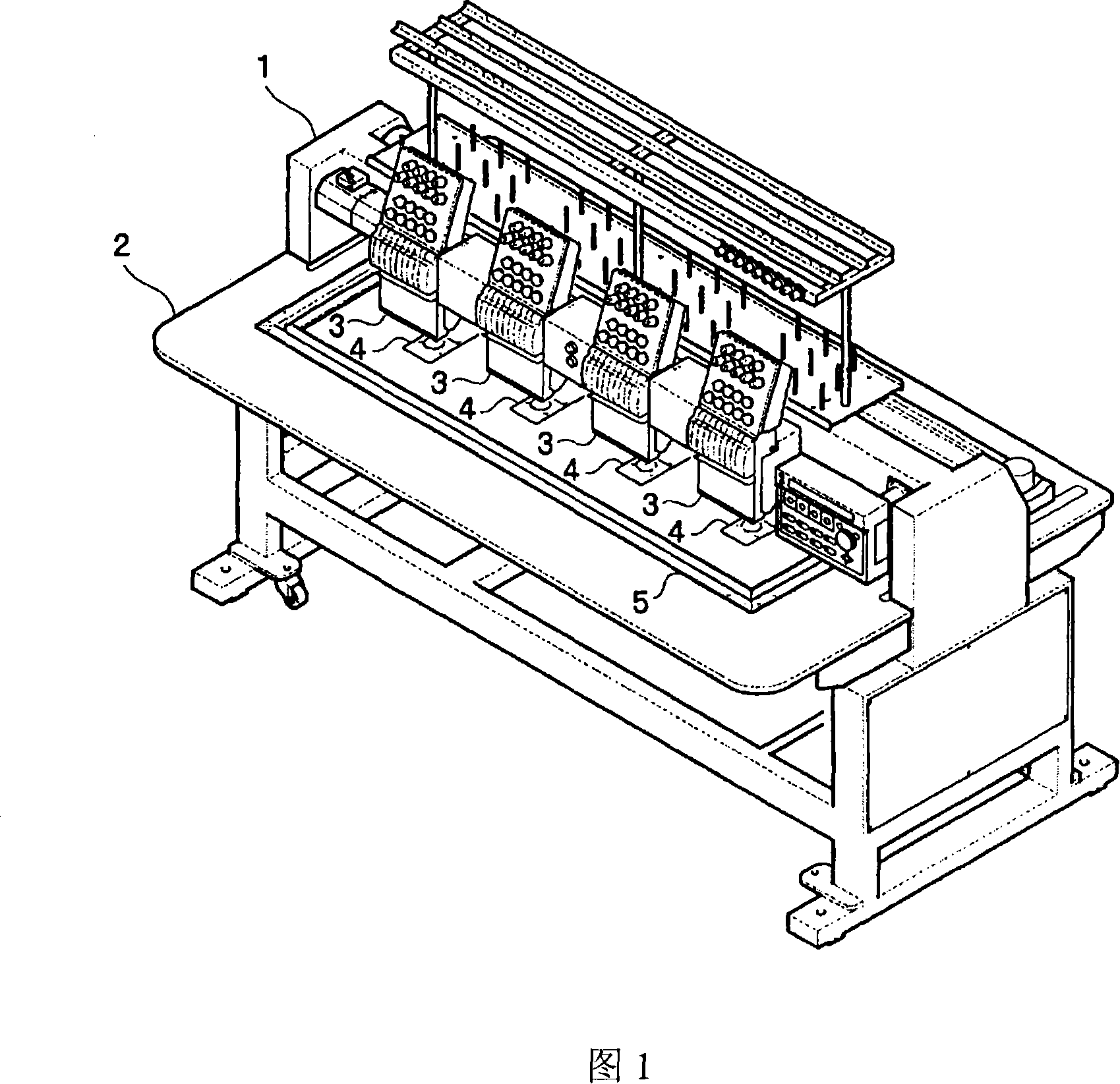

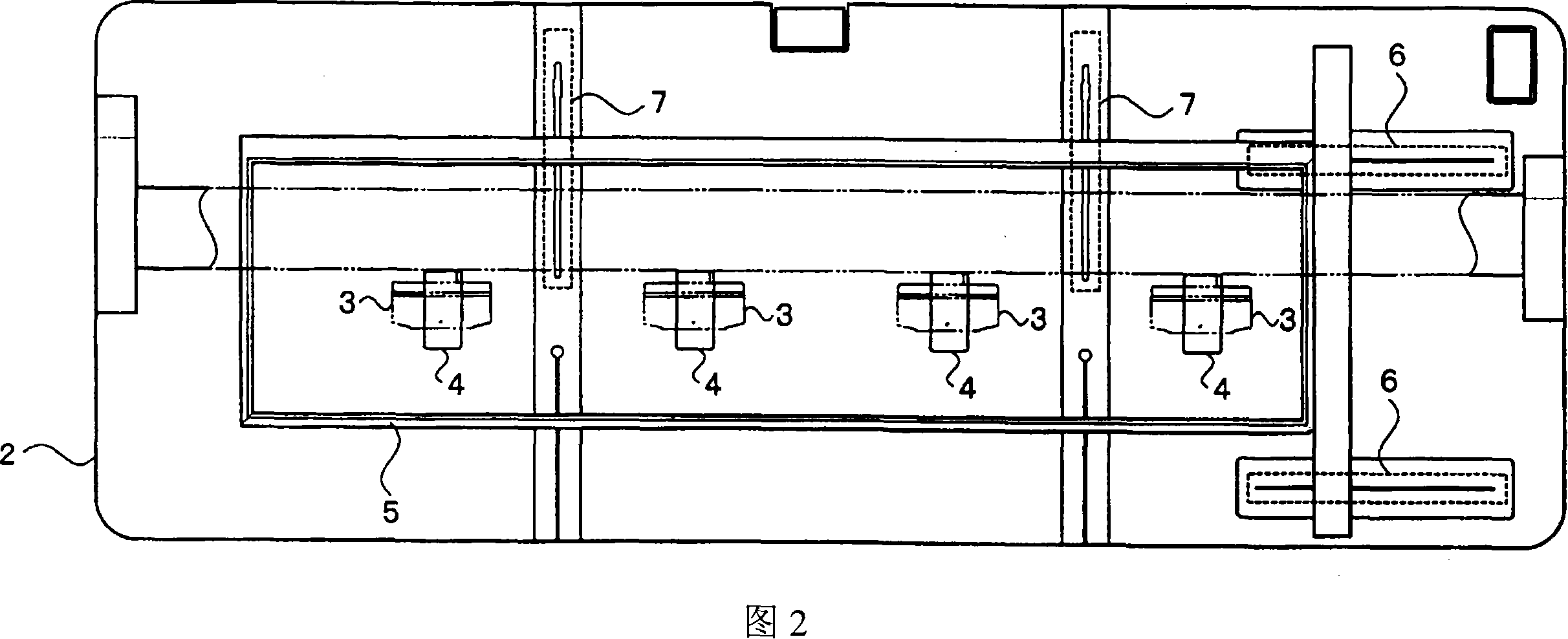

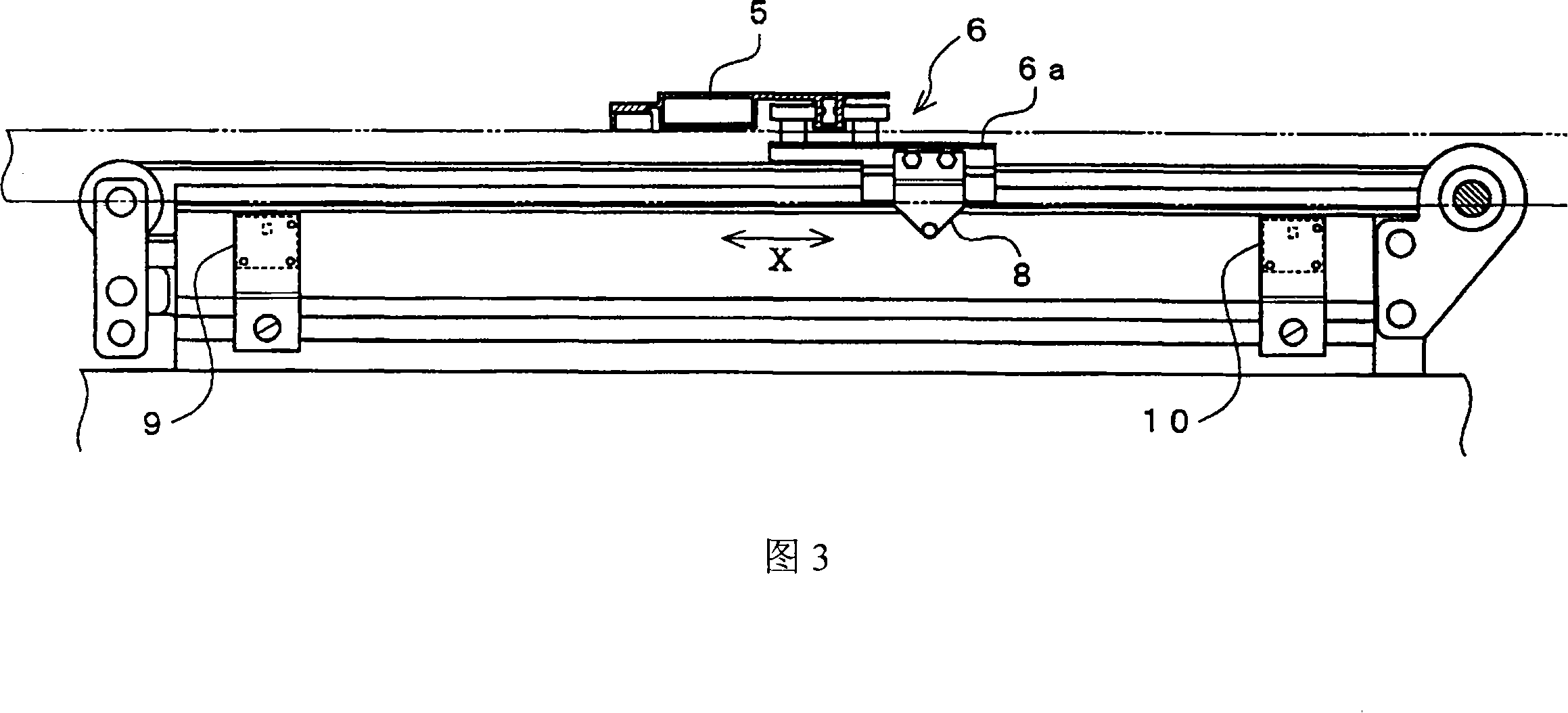

[0021] Fig. 1 is an appearance view of an embroidery sewing machine according to an embodiment of the present invention, and the appearance itself is the same as that of a known embroidery sewing machine. On the sewing machine frame 1, a plurality of (four in the illustrated example) sewing machine heads 3 are arranged at regular intervals along the left and right direction of the sewing machine, and the height and working table are arranged directly below the sewing machine head 3. The upper surface of 2 is roughly the same as the needle plate 4. As shown in the top view of FIG. 2 , an embroidery stand 5 that holds the object to be embroidered is provided on the workbench 2 so as to be movable in the X / Y direction of the plane. The embroidery frame 5 is driven two-dimensionally in the X / Y direction by the X-axis driving mechanism 6 and the Y-axis driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com