Method for operating an internal combustion engine

A technology of internal combustion engines and sensors, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as failure to identify high-voltage generating devices, and achieve the effect of preventing engine flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

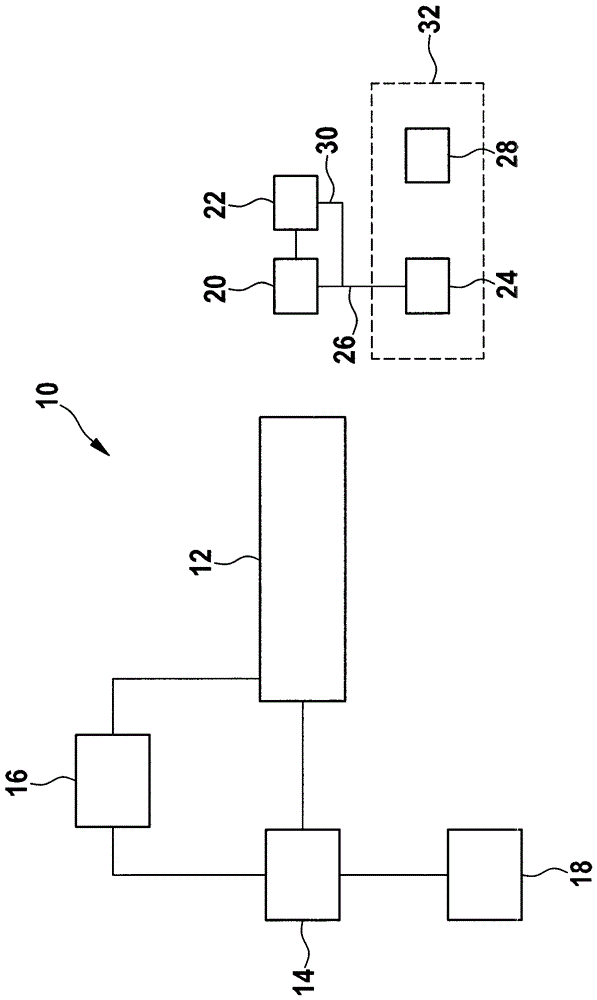

[0019] The invention is schematically shown in the drawing with the aid of an embodiment and will be explained in more detail below with reference to the drawing.

[0020] There is shown an internal combustion engine 10 with a pressure accumulator or rail 12 into which fuel is entered by means of a high pressure pump 14 and held there for direct injection into a combustion chamber (not shown). The pressure in the pressure accumulator 12 is adjusted by means of a pressure regulating device 16 . Furthermore, the drawing shows a prefeed pump 18 and a lambda sensor 20 with a regulator 22 .

[0021] If a fault then occurs in the high-pressure pump 14 or the pressure regulating device 16 , the pressure in the pressure accumulator 12 drops. This was not directly noticed because no pressure detectors were installed. Since the selected injection time is adapted to the pressure supplied jointly by the prefeed pump 18 and the high-pressure pump 14 , this results in too little petrol in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com