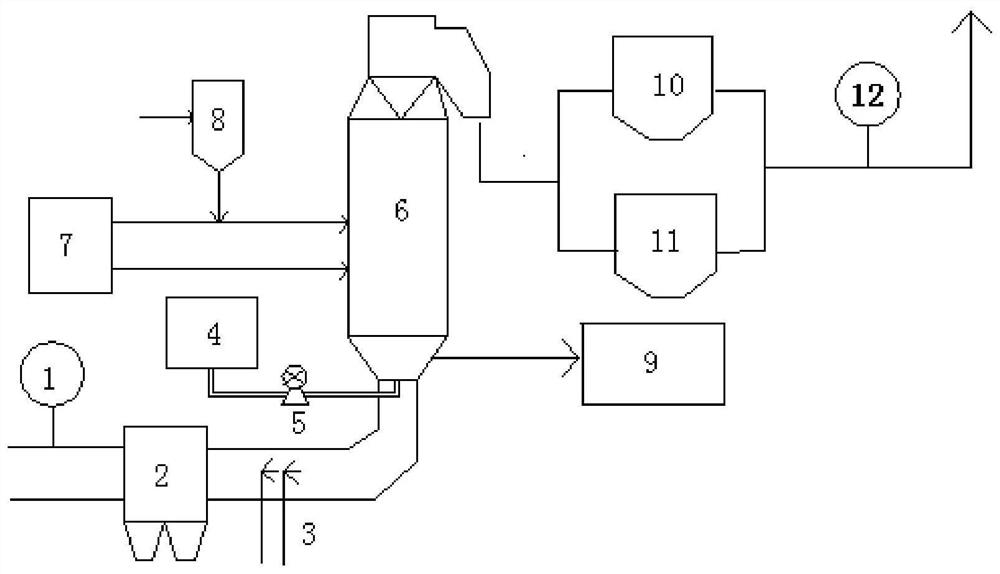

Integrated device and method for denitrification and mercury removal in sintering flue gas circulating fluidized bed desulfurization

A circulating fluidized bed and sintering flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low solubility, difficulty in controlling mercury, mercury pollution, etc., and achieve wide sources, easy absorption, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: The flue gas volume of sintering flue gas is 1 million Nm 3 / h, where SO 2 The content is 650~800mg / Nm 3 , NO X The content is 200~280mg / Nm 3 , the oxygen content is 13-16%, and the water content is 5-7%. When the flue gas enters the pipeline through the electrostatic precipitator, the prepared component A of the denitrification oxidant is sprayed into the flue with a high-pressure spray gun, and the formed mist water vapor fully contacts with the flue gas, and quickly oxidizes NO to NO 2 , SO 2 in Fe 3+ Catalyzed by ions into SO 3 , consume about 276-387Kg / h of denitrification oxidizer A component. At the same time, the lime is added into the pipeline where the industrial water tank is located through the digestion tank, and the B component of the denitration reduction absorbent in the denitration reduction absorbent tank is sprayed into the bottom of the CFB reactor through the denitration pump, and then enters the CFB reactor to participate in the r...

Embodiment 2

[0055] Example 2: The flue gas volume of sintering flue gas is about 1.3 million Nm 3 / h, where SO 2 The content is 680~850mg / Nm 3 , NO X The content is 210~250mg / Nm 3 , the oxygen content is about 14-16%, and the water content is about 8-10%. When the flue gas enters the pipeline through the electrostatic precipitator, the prepared component A of the denitrification oxidant is sprayed into the flue with a high-pressure spray gun, and fully contacts with the flue gas to quickly oxidize NO to NO 2 , SO 2 in Fe 3+ Catalyzed by ions into SO 3 , about 364.7-432.9Kg / h of denitrification oxidant component A is consumed. At the same time, the lime is added into the pipeline where the industrial water tank is located through the digestion tank, and the B component of the denitration reduction absorbent in the denitration reduction absorbent tank is sprayed into the bottom of the CFB reactor through the denitration pump, and then enters the CFB reactor to participate in the reac...

Embodiment 3

[0056] Example 3: The flue gas volume of sintering flue gas is about 1.6 million Nm 3 / h, where SO 2 The content is 800~1000mg / Nm 3 , NO X The content is 250~280mg / Nm 3 , the oxygen content is about 15-16%, and the water content is about 10-11%. When the flue gas enters the pipeline through the electrostatic precipitator, the prepared component A of the denitrification oxidant is sprayed into the flue with a high-pressure spray gun, and fully contacts with the flue gas to quickly oxidize NO to NO 2 , SO 2 in Fe 3+ Catalyzed by ions into SO 3, about 523.2-583.2Kg / h of component A of the denitrification oxidant is consumed. At the same time, the lime is added into the pipeline where the industrial water tank is located through the digestion tank, and the B component of the denitration and reduction absorbent in the denitration and reduction absorbent tank is sprayed into the bottom of the CFB reactor through the denitration pump, and then enters the CFB reactor to partici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com