Jaw movable motor

A technology of feeding and docking parts, which is applied in the field of injection machines, can solve problems such as poor injection accuracy, increased cleaning frequency of injection machines, and inability to estimate, so as to achieve accurate injection of plastic or rubber raw materials, saving raw materials and production costs, integrity and overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

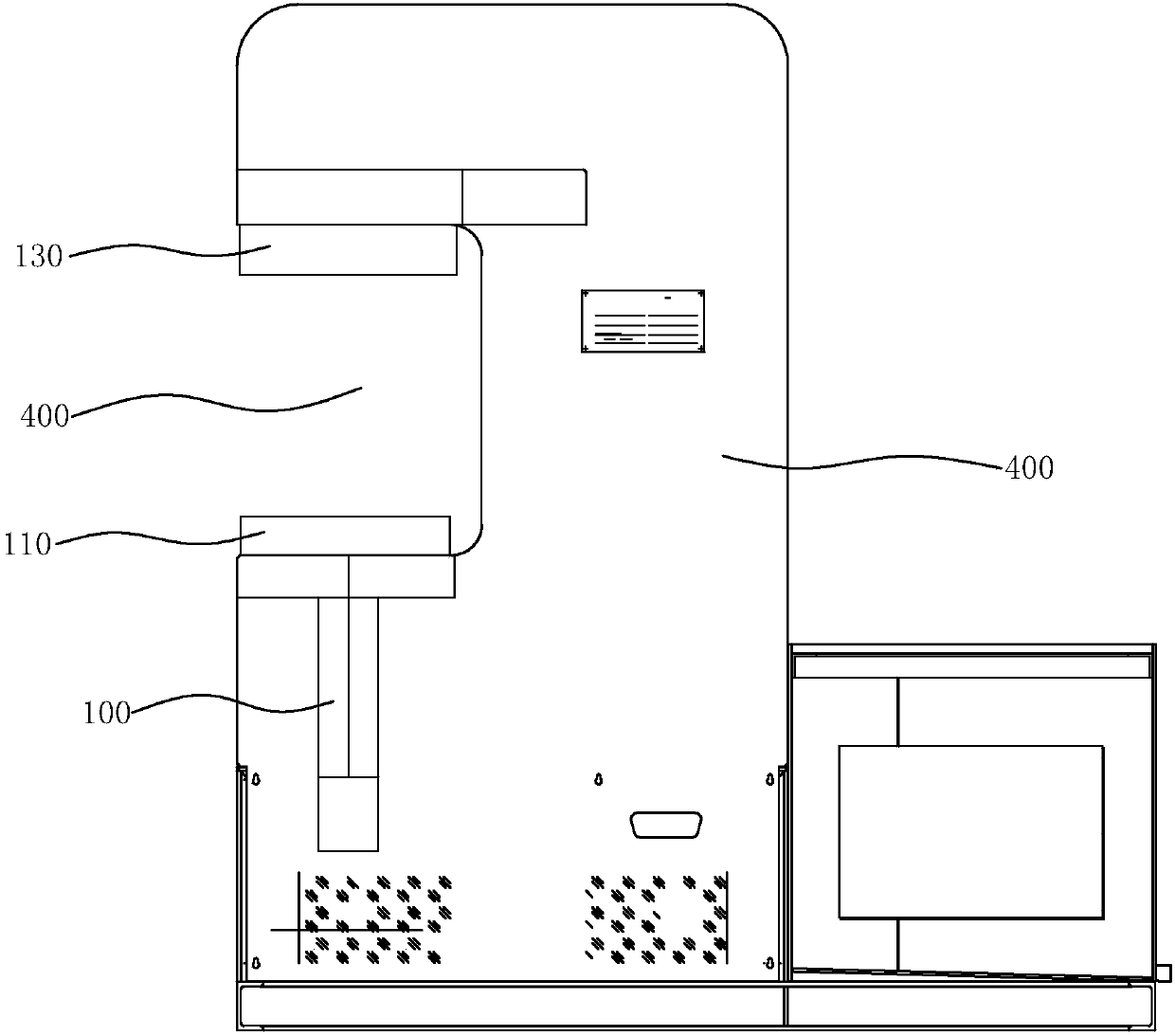

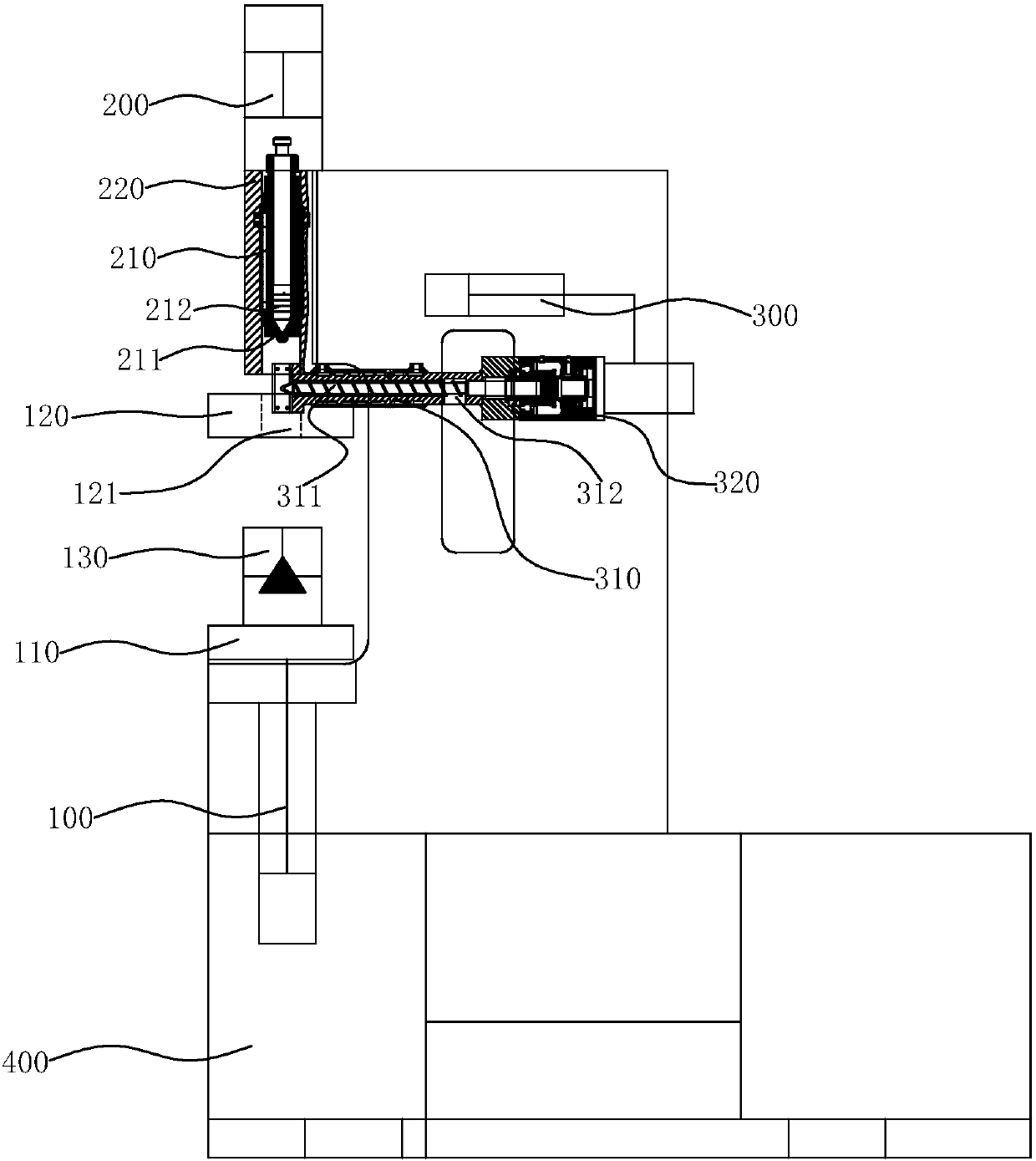

[0024] Such as figure 1 , figure 2 As shown, a palate-moving motor of the present invention is installed on a base 400. The shape of the base 400 is a vertical rectangle. A gap 410 is opened on one side of the base 400. The shape of the gap 410 is " C” shape.

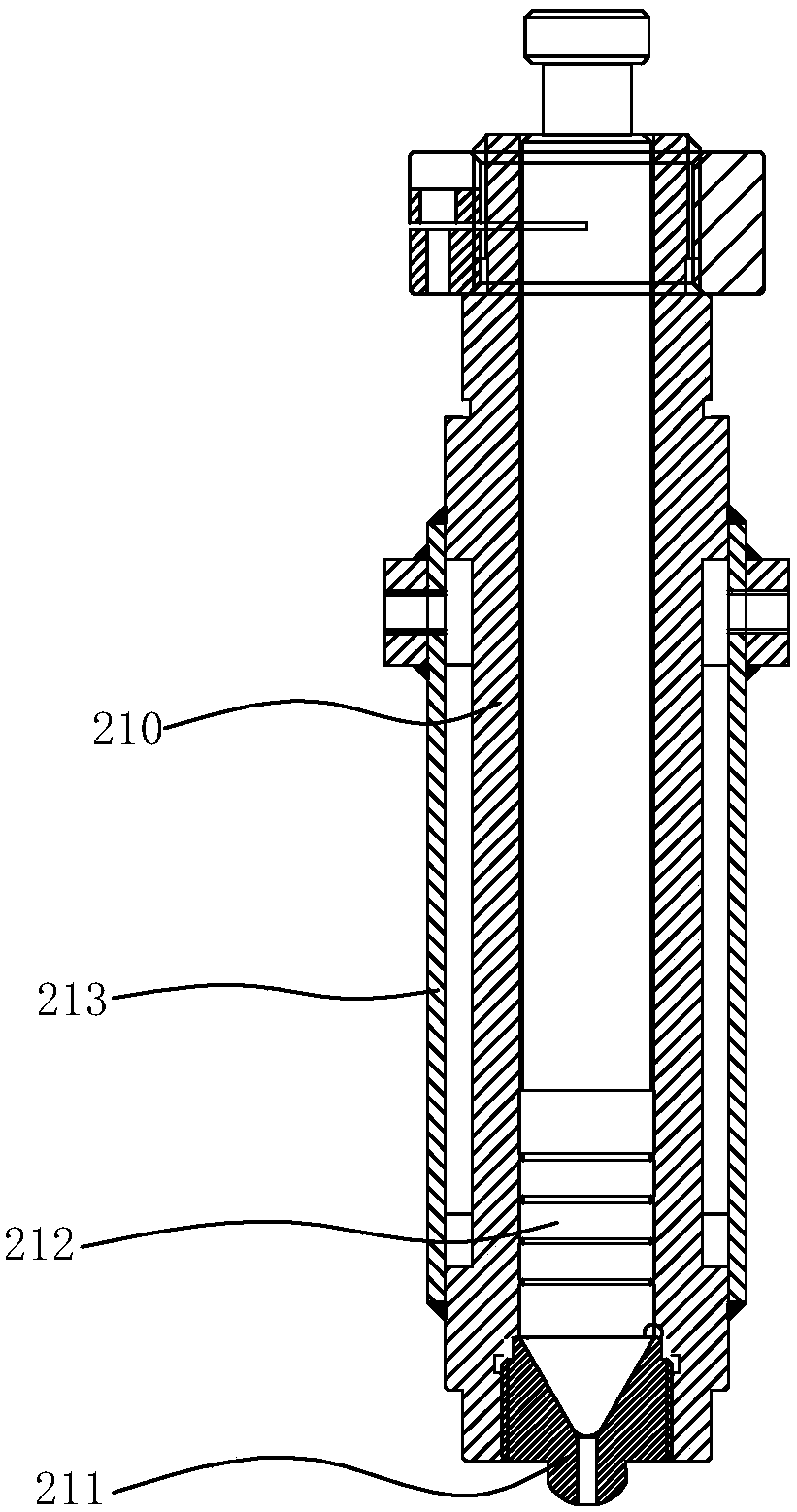

[0025] Further, on the base 400 at the top part of the notch 410, a cartridge holder 220 is vertically arranged, and the injection cartridge 210 is installed in the cartridge holder 220, and a first slide rail is installed on the inner wall of the cartridge holder 220, and the injection cartridge A sliding part 213 is correspondingly installed on the outer wall of the 210, and the sliding part 213 is located on the first slide rail so that the injection barrel 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com