Material transmitting device for automatically folding and sewing

An automatic cloth-pressing device technology, which is applied in the direction of feeding devices, sewing equipment, sewing machine components, etc., can solve the problems of high labor intensity, unguaranteed stitching quality, and low work efficiency, so as to reduce labor intensity and improve The effect of work efficiency and suture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

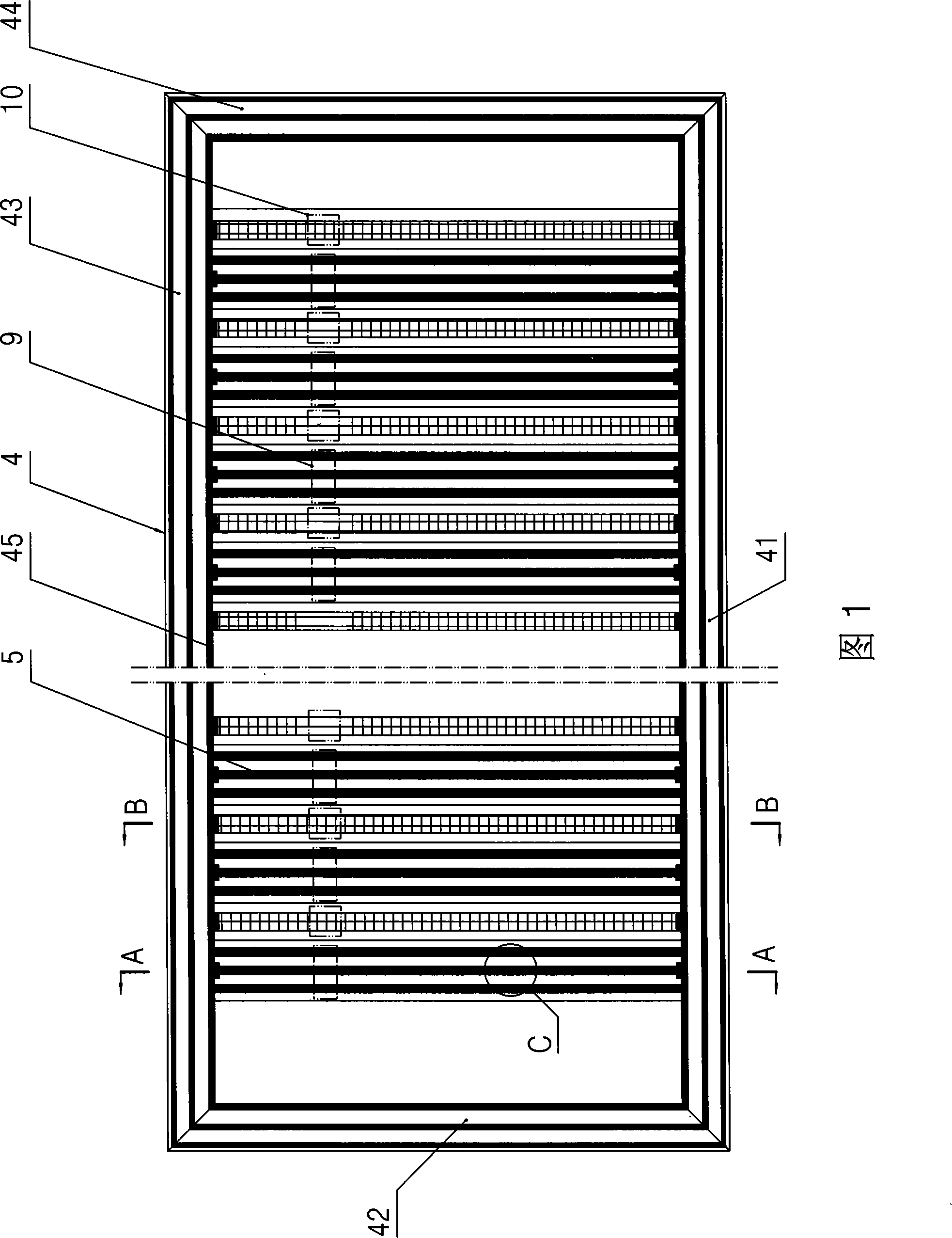

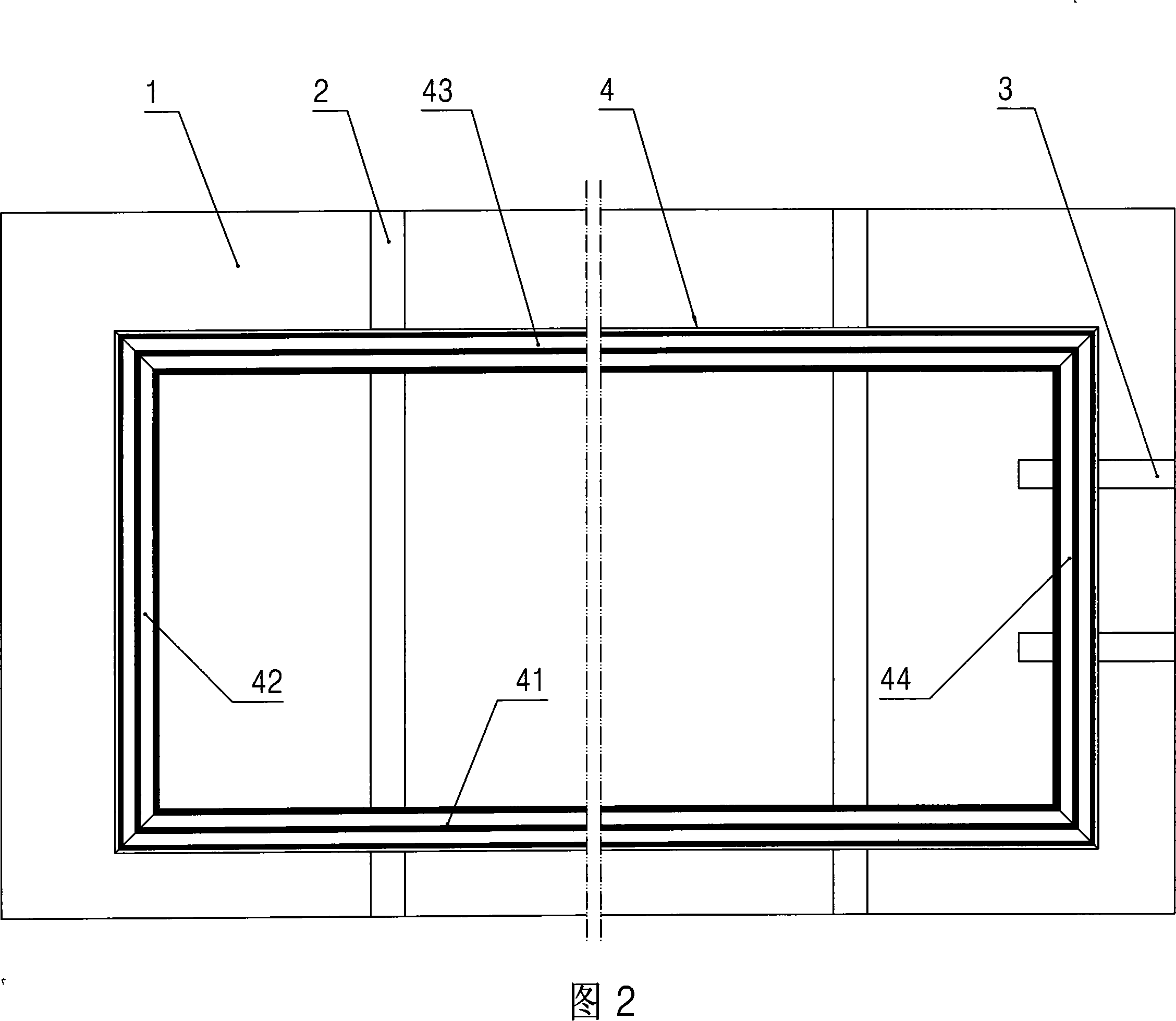

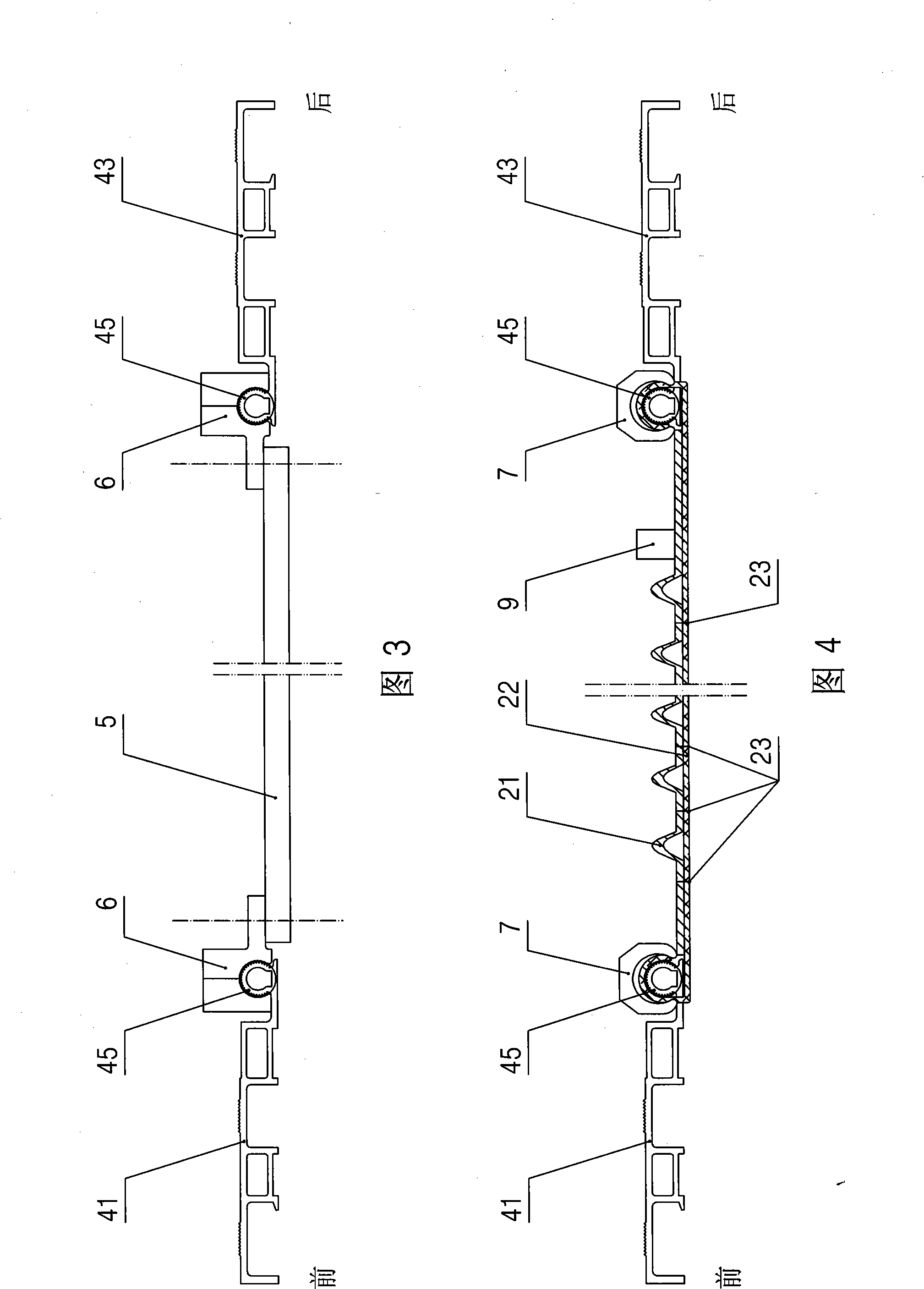

[0017] Such as figure 1 , figure 2 As shown, the feeding device for automatic folding and sewing of the present invention includes: a worktable 1 arranged on the frame, and the worktable 1 is slidably provided with front and rear gears 41 and 43 and left and right gears. The mobile frame 4 composed of 42 and 44, that is, the mobile frame 4 can perform horizontal and vertical two-dimensional translation movements on the work surface 1, and its setting method is: a pair of longitudinal guide grooves 2 and a pair of transverse guide grooves are arranged in the work surface Slot 3, a pair of longitudinal sliders are movably arranged in each longitudinal guide groove 2, and the tops of each pair of longitudinal sliders are respectively movably arranged in the transverse chute at the bottom of the front and rear shelves 41 and 43, and the two long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com