Off-axis reflection optical lens focus detection method

An optical lens, off-axis reflection technology, applied in the field of optical inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

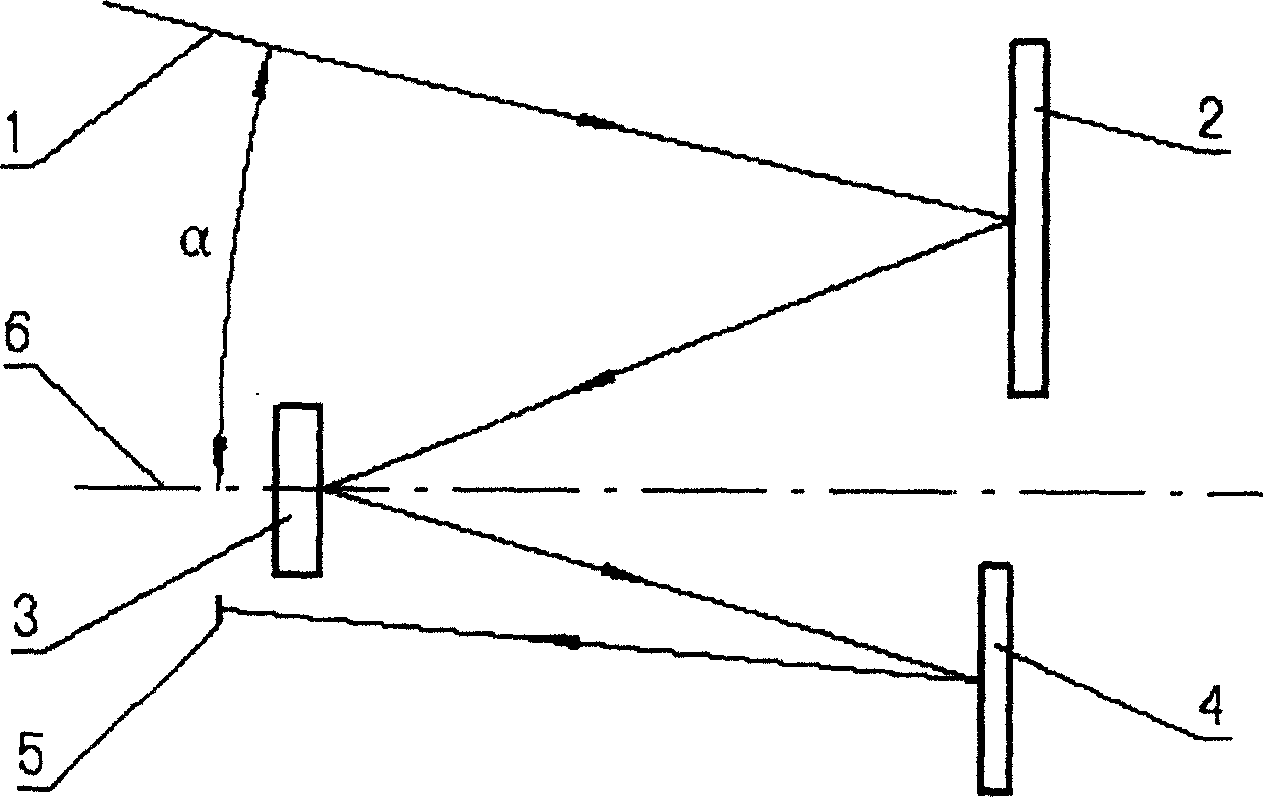

Method used

Image

Examples

Embodiment Construction

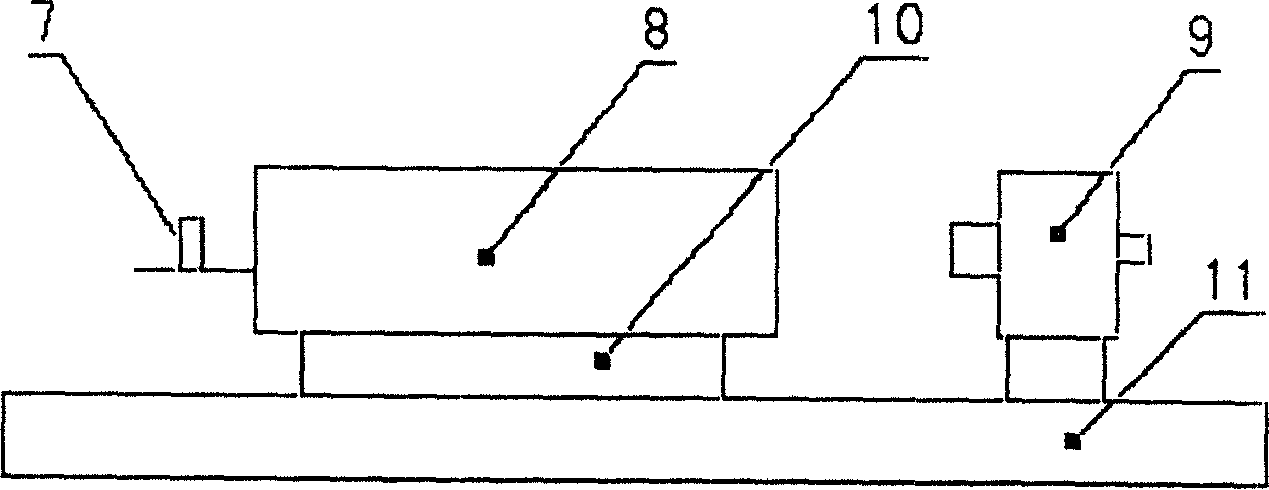

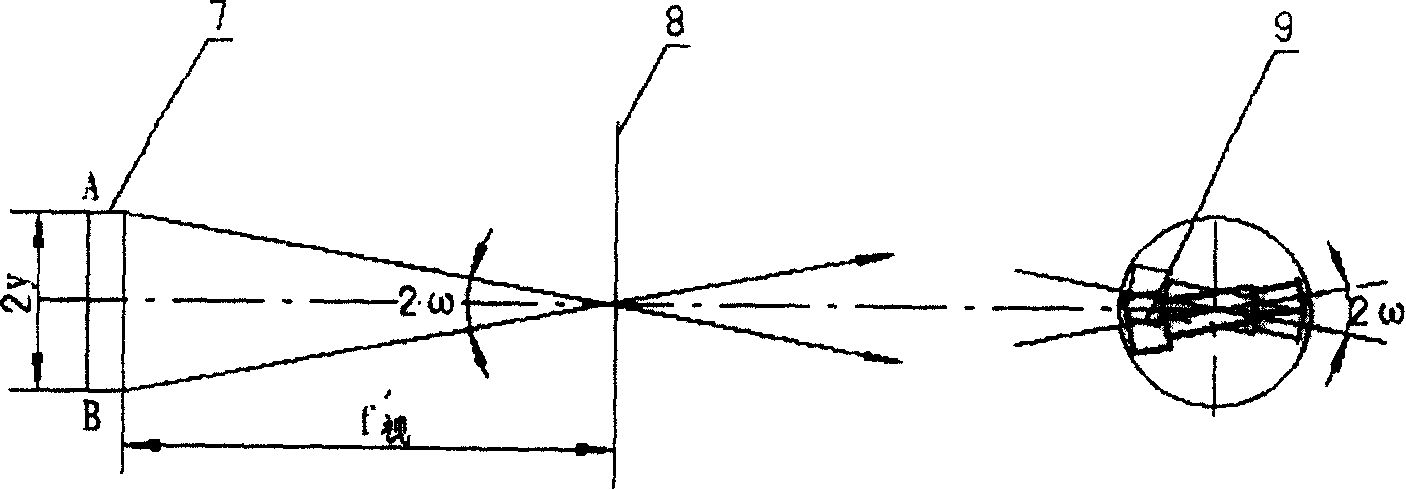

[0016] The present invention implements according to the technical scheme that solves technical problem. Before the test, the reflective optical lens 8 to be tested should be placed in the optical testing laboratory at a constant temperature for 24 hours to balance the temperature of the lens. During the test, the reticle 7 of suitable line width and spacing is selected according to the design focal length of the lens to be checked and the detection accuracy, which is conducive to the improvement of theodolite 9 aiming accuracy, and the reticle material generally adopts optical glass; 0.5″ or 2″ theodolite, determined by the focal length test accuracy requirements; the adjustment tooling 10 should be adjustable and stable; the optical platform 11 should have an array foundation to avoid the influence of vibration; To improve the aiming accuracy, the method of aiming at the front and back mirrors and taking the average value is adopted; the test should be carried out in an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com