Display device and display panel driver using grayscale voltages which correspond to grayscales

A grayscale voltage and display device technology, applied to static indicators, instruments, and conversion equipment without intermediate conversion to AC, etc., can solve problems such as image quality degradation, and achieve the effect of improving quality and stabilizing grayscale voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

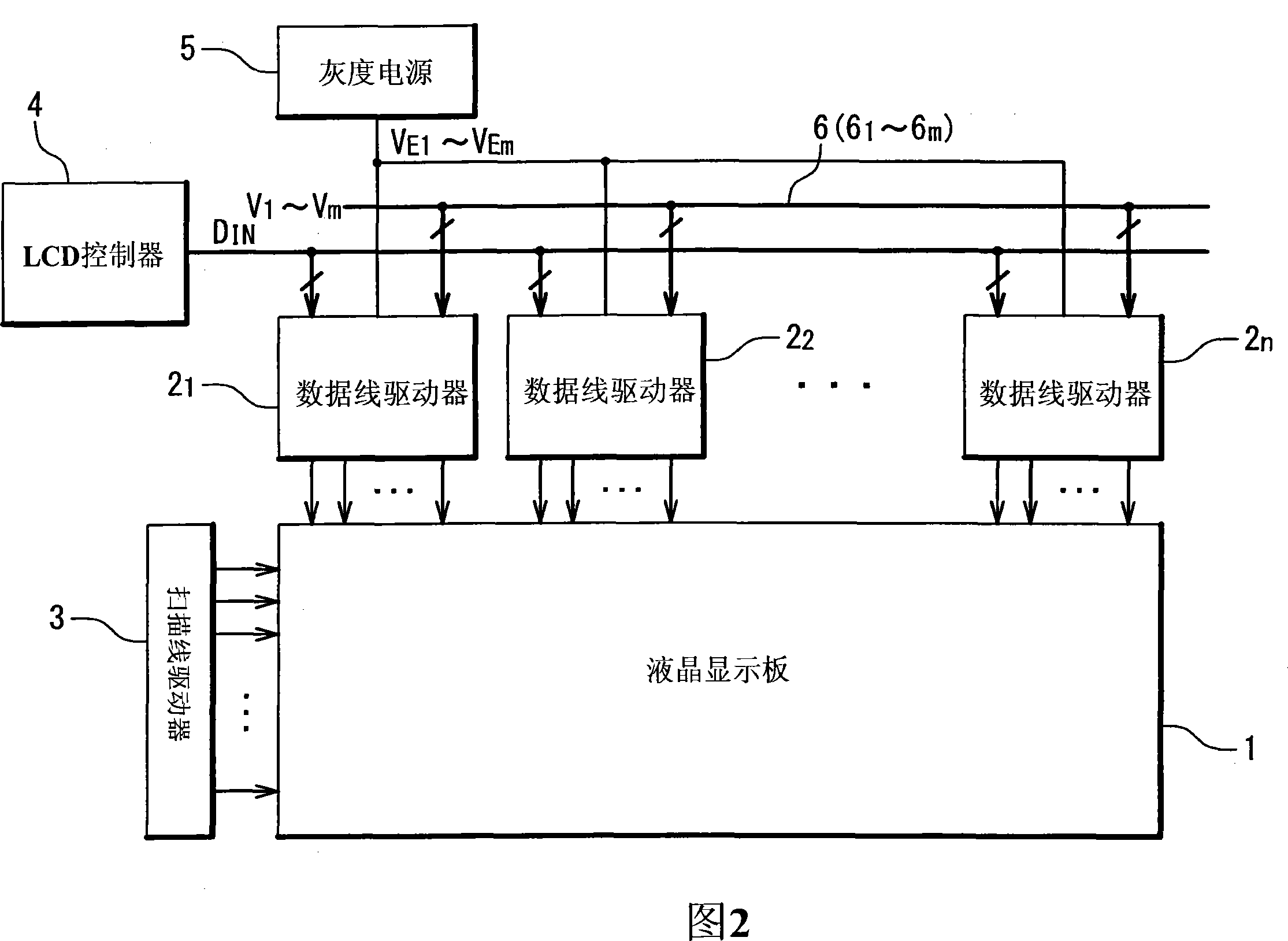

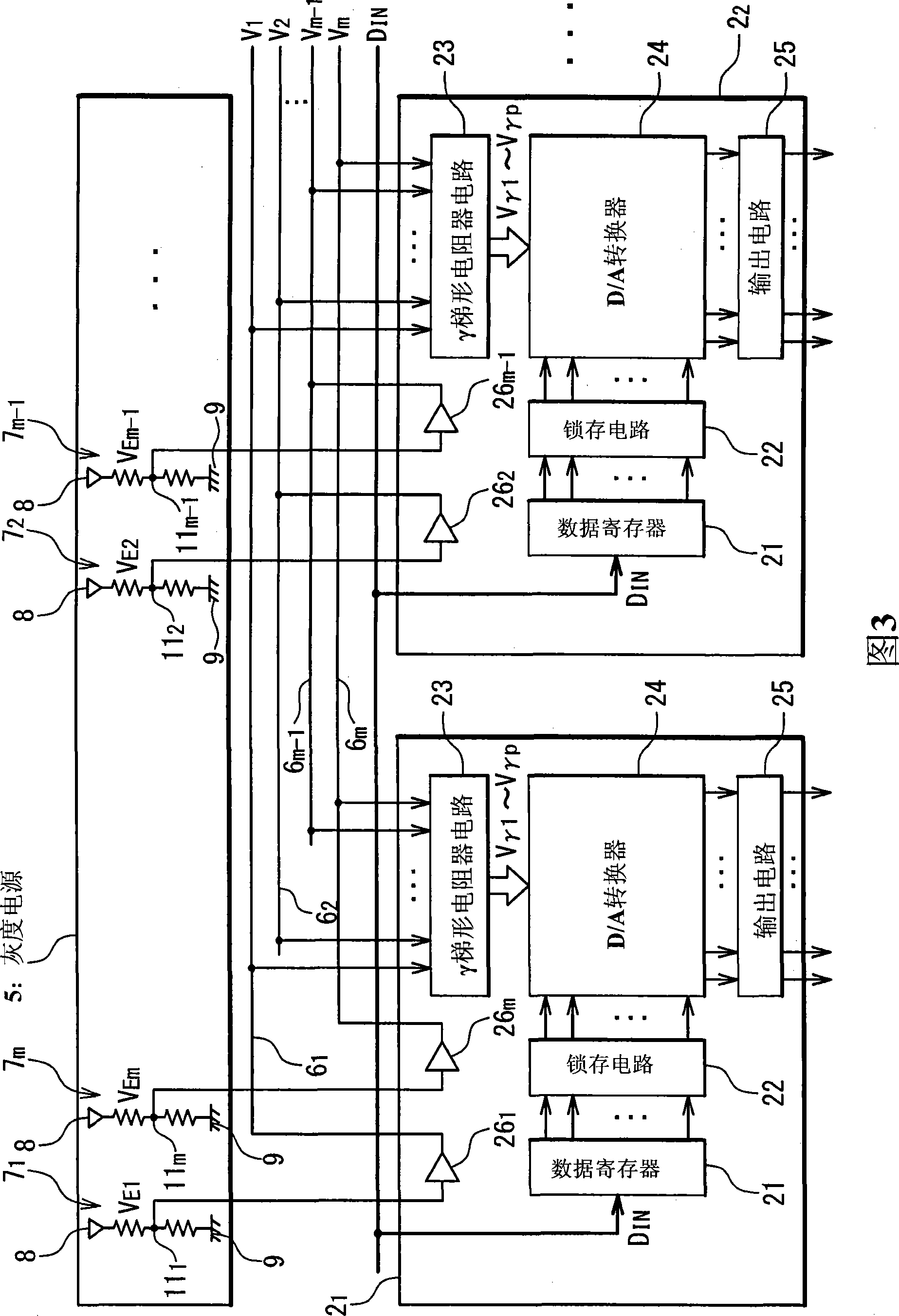

[0030] figure 2 is a block diagram showing the structure of the liquid crystal display device according to the first embodiment of the present invention. The liquid crystal display device includes: a liquid crystal display panel 1; a data line driver 2 1 to 2 n ; Scanning line driver 3; LCD controller 4; Data Line Driver 2 1 to 2 n The data lines (not shown) of the liquid crystal display panel 1 are driven. The scanning line driver 3 drives scanning lines (not shown) of the liquid crystal display panel 1 . LCD controller 4 to data line driver 2 1 to 2 n The pixel data D for displaying the gradation of each pixel on the liquid crystal display panel 1 is supplied IN . In addition, the LCD controller 4 gives the data line driver 2 1 to 2 n and scanning line driver 3 supply control signals (not shown), thereby controlling the data line driver 2 1 to 2 n and scan line driver 3 .

[0031] The grayscale power supply 5 is used to generate the grayscale power supply volt...

no. 2 example

[0049] Depending on the manufacture of each liquid crystal display device, the combination of reference voltages required by the manufacture of the liquid crystal display device may be different. More specifically, some manufacturing may require the supply of m reference voltages V 1 to V m to the data line driver, while another fabrication may require omitting the second maximum reference voltage V 2 and the second minimum reference voltage V m-1 supply.

[0050] Figure 7 is shown in the absence of supply reference voltage V 2 and V m-1 Schematic diagram of the operation of the γ ladder resistor in the case of . Reference signs indicate the same Figure 4 The same components shown in. One of the problems that arises in meeting the above two manufacturing requirements at the same time is that, if Figure 7 shown in, if the reference voltage V is omitted 2 and V m-1 With the configuration of the gamma ladder resistor circuit 23 of the first embodiment, the required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com