Paper crusher

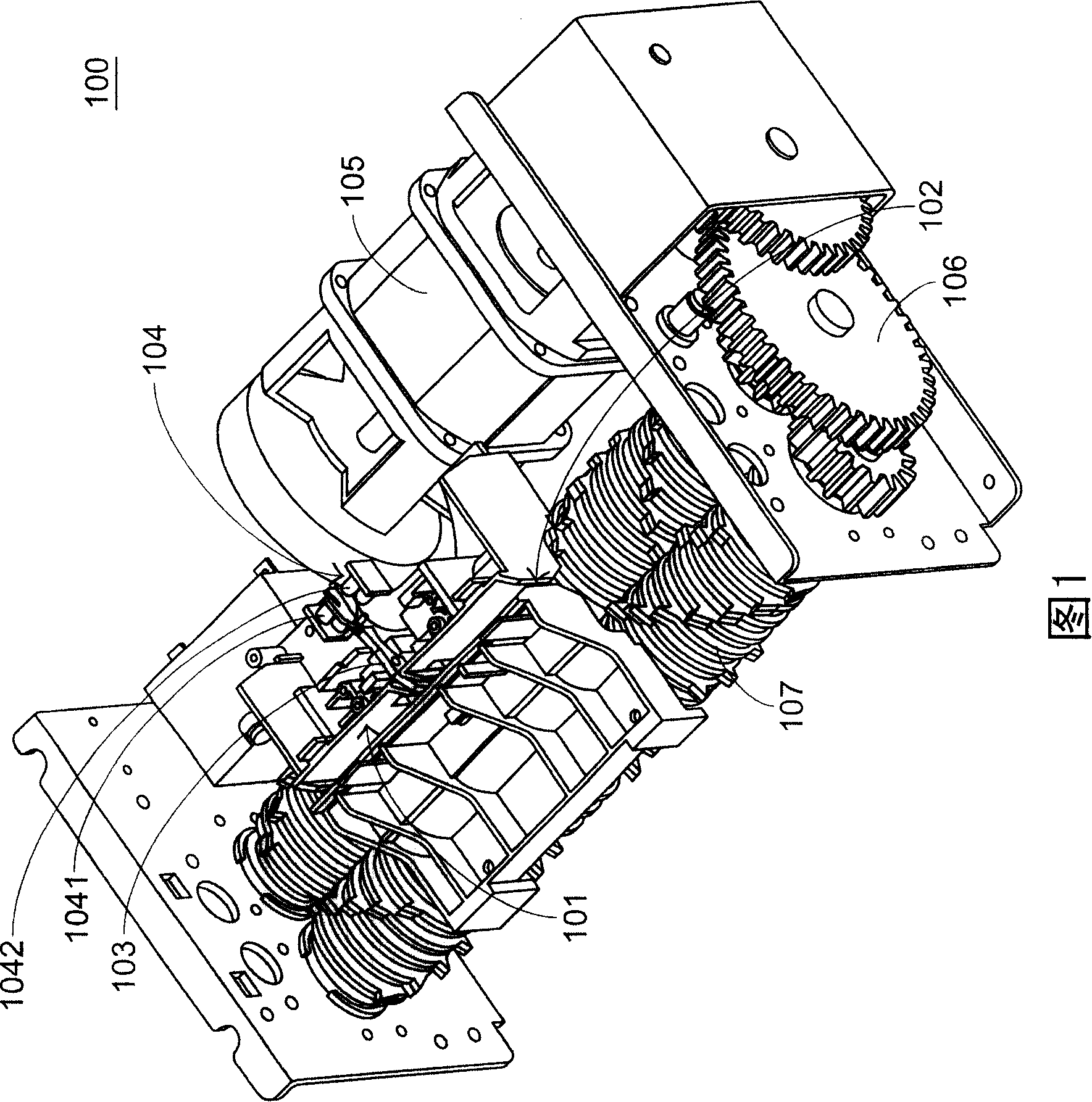

A paper shredder and paper shredding technology, which is applied in the direction of grain processing, etc., can solve the problems that the object to be shredded violently shakes, and the paper shredder 100 cannot successfully complete the shredding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

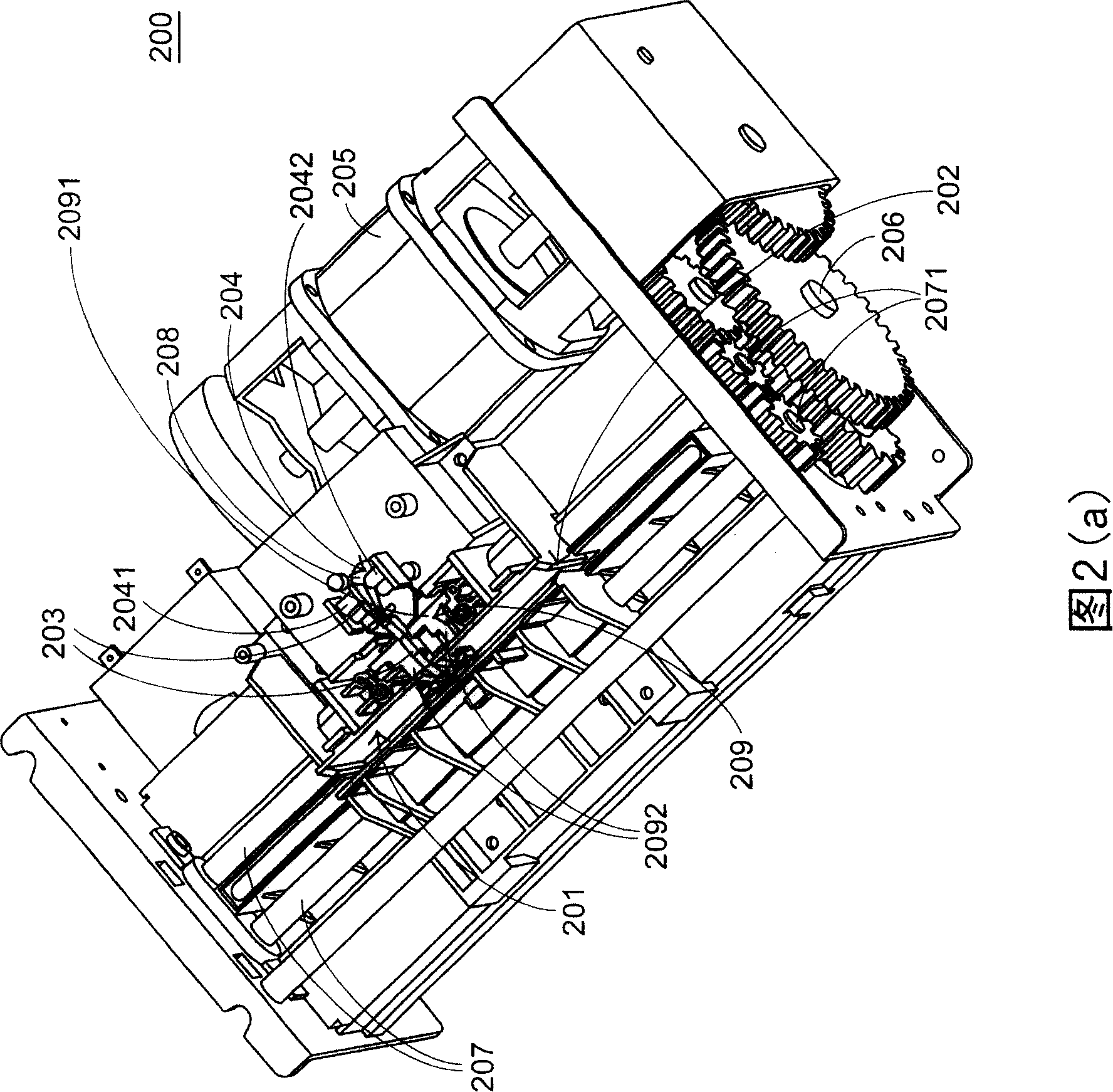

[0035] In order to improve the shaking problem of the objects to be crushed in the prior art, the main technical feature of the present invention is that a movable abutment mechanism is provided around the toggle assembly, wherein the abutment mechanism includes a push assembly and a press assembly. The pushing component and the pressing component can be arranged at the required matching positions according to the different designs of the shredder. In this way, during the paper shredding process, the resisting mechanism is used to withstand the shaking objects to be shredded, which can prevent the toggle assembly from malfunctioning due to being squeezed by the objects to be shredded, thereby ensuring the normal operation of the shredder. Work.

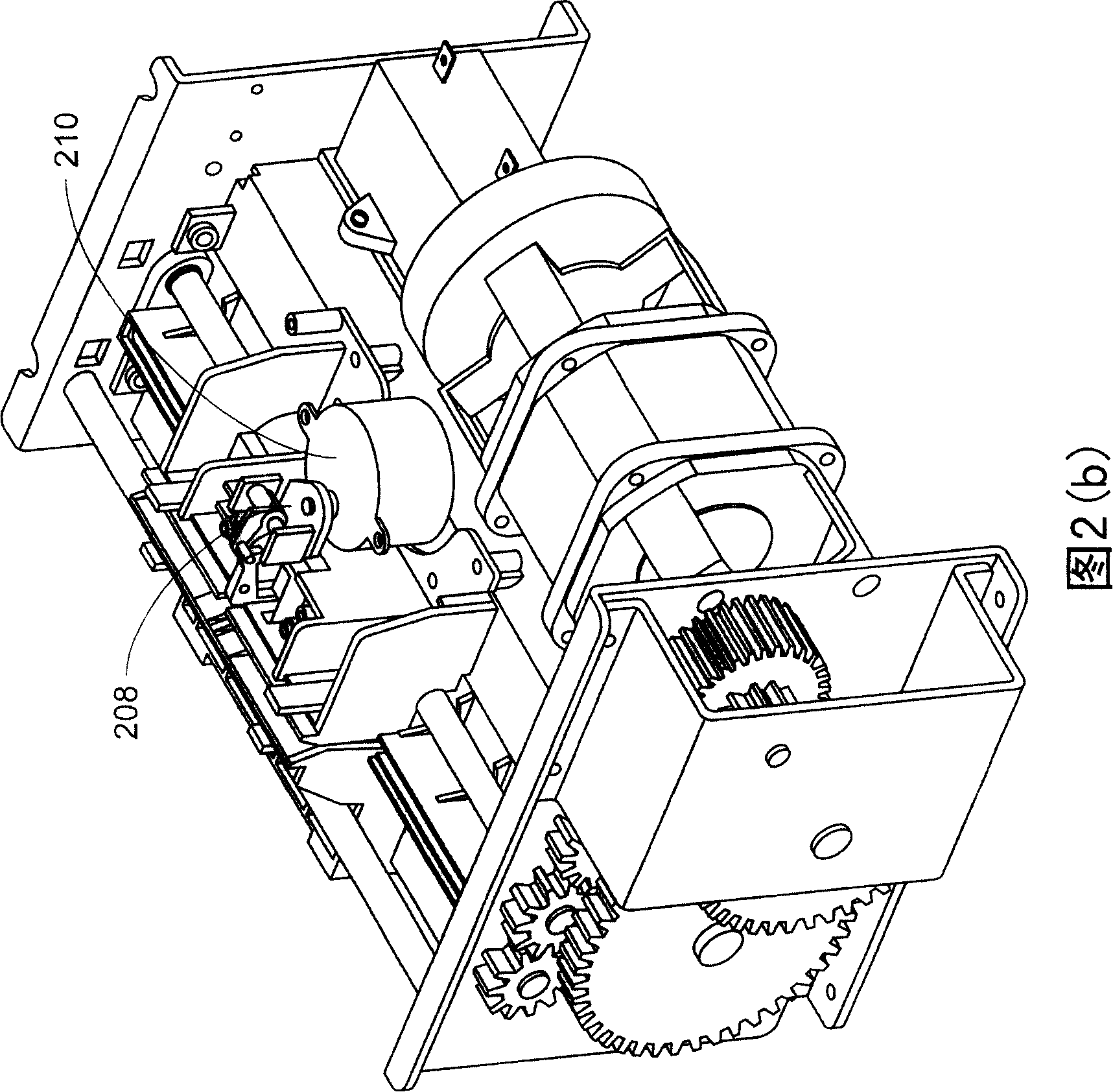

[0036] Please refer to FIG. 2( a ), FIG. 2( b ), FIG. 2( c ), and FIG. 2( d ), which are schematic views from different angles of an embodiment of the present invention. As shown in Figure 2(a), in the paper shredder 200, the paper thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com