Full-automatic impeller type washing machine with water lifted by pump

A fully automatic, pulsator-type technology, applied in the field of washing machines, can solve the problems of unsatisfactory collection of washing lint and large amount of water used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

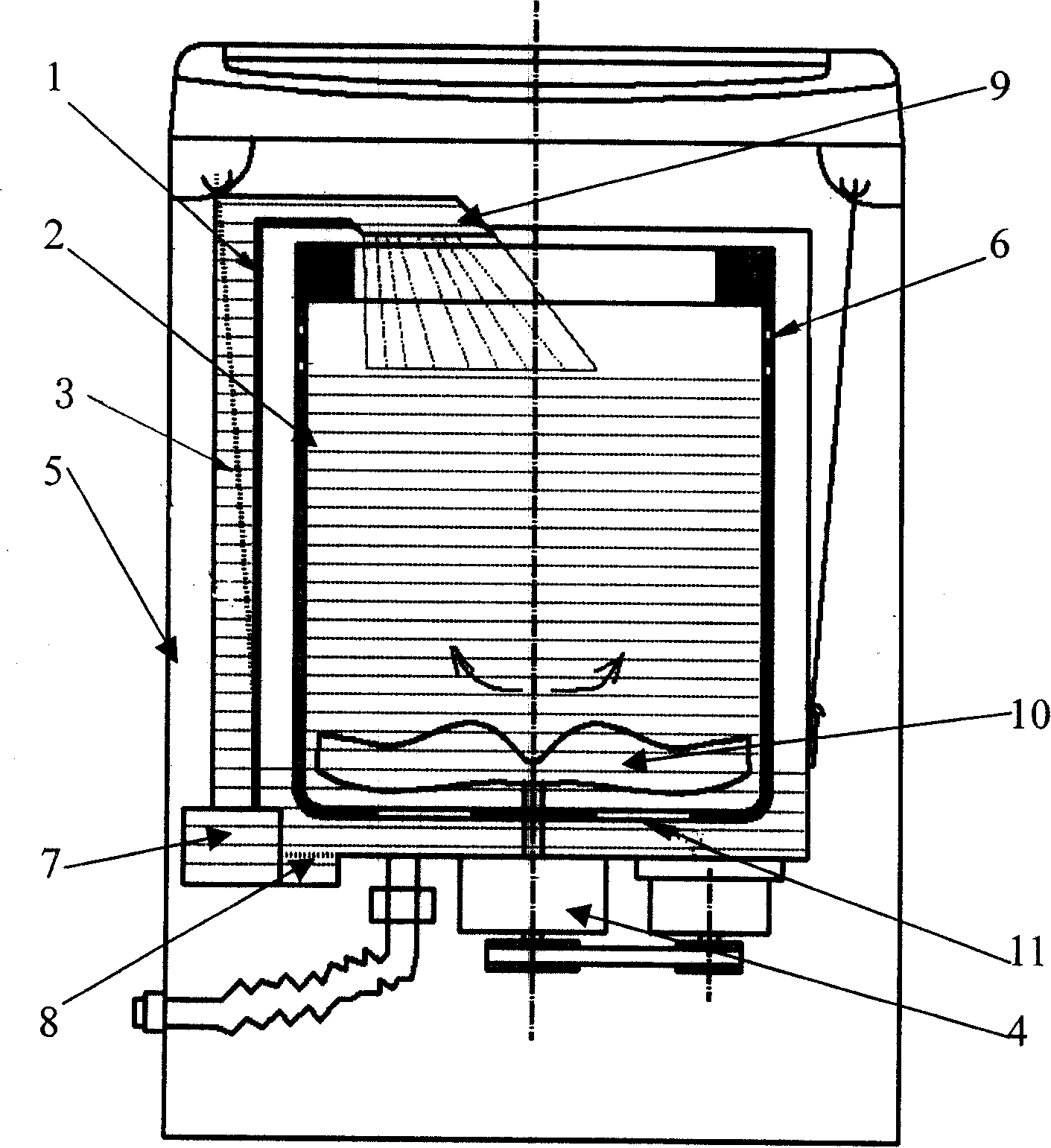

[0015] Such as figure 1 The shown pump lifting water automatic pulsator washing machine has a water tank 1 inside the tank 5, and a lower non-porous washing and dehydrating bucket 2 inside the water tank 1. The lower non-porous washing and dehydrating bucket is There is only one or more rows of dehydration through holes 6 on the top of the bucket wall, which can be 1 row or 2 to 4 rows, and the bottom of the bucket wall has no holes and has a certain water retention effect; A pulsator 10 is installed at the bottom of the washing and dehydrating bucket 2, and the pulsator is driven by the driving mechanism 4. The back side of the pulsator is a smooth surface, and there is no tendon structure for fetching water, so that the pulsator only has the function of stirring the clothes during washing. Can effectively reduce the power consumption of the motor. The water tank 1 is provided with a water pump circulation system connected with the water flow of the washing and dehydration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com