Protective film assembly container

A technology of protective film and storage container, which is applied to instruments, electrical components, original parts for opto-mechanical processing, etc. The effect of the chance of the pellicle assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

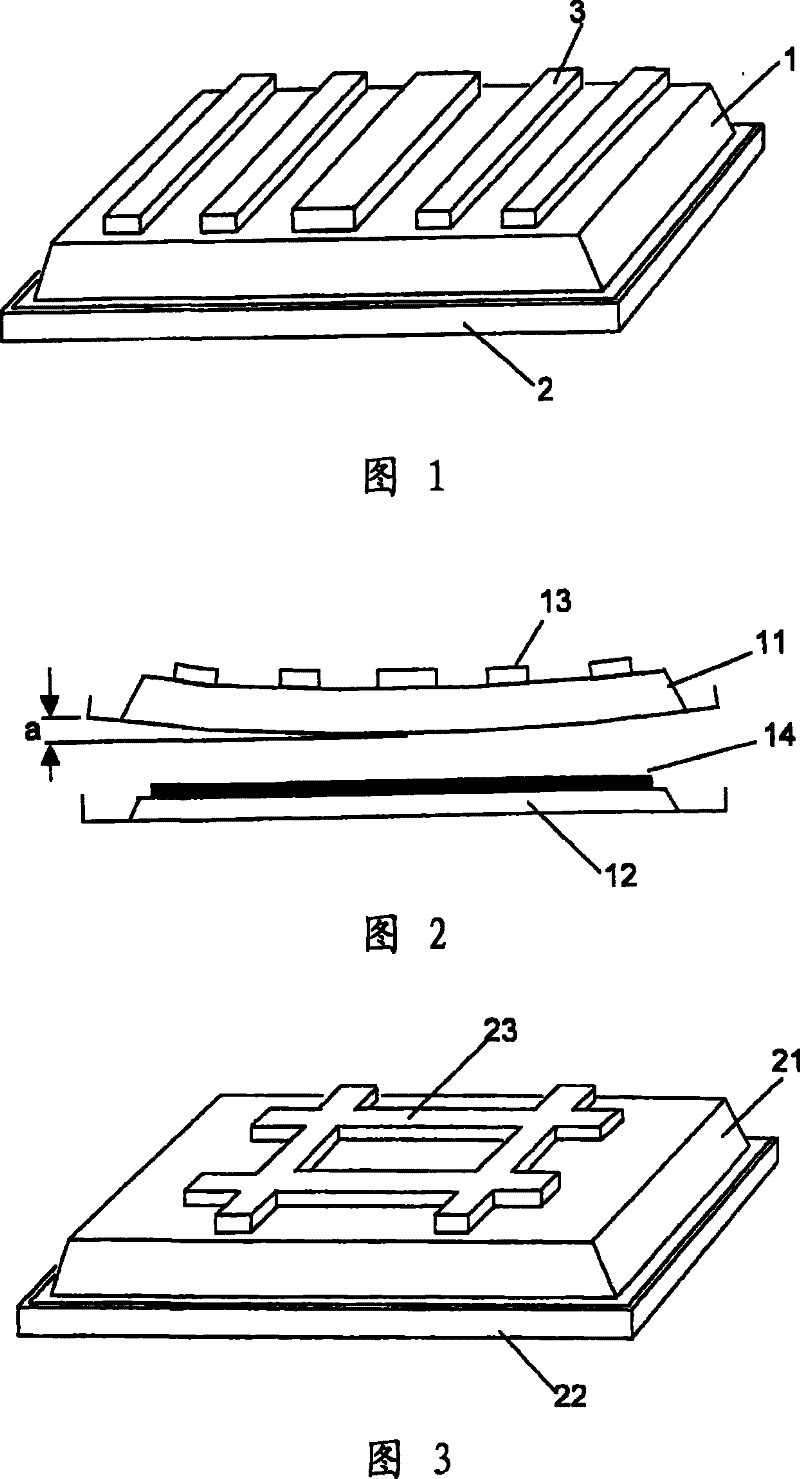

[0063] Hereinafter, embodiments of the present invention will be described, but the present invention is not limited thereto. The antistatic ABS resin sheet (t=3mm, black) is made into a pellicle container body 2 having a shape as shown in FIG. 1 by vacuum forming.

[0064] The central part of the container body is relatively high, and the protective film assembly can be placed thereon.

[0065] Next, an ABS resin sheet (t=3 mm, transparent) capable of preventing static electricity was manufactured into a cover body 1 having a shape as shown in FIG. 1 by vacuum forming. The cover body 1 is provided with ribs 3 at five places on the upper surface, the ribs at four places have a height of 20 mm and a width of 50 mm, and the central rib has a height of 20 mm and a width of 100 mm.

[0066] Certainly, the cover body 1 can be fitted on the container body 2, and the assembled appearance is as shown in FIG. 1 . The overall size is length 1450×width 1330×height 95mm.

[0067] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com