Immersion flow field stabilizing device used for photo-etching machine

A technology for stabilizing devices and lithography machines, applied in photolithography exposure devices, micro-lithography exposure equipment, etc., can solve problems such as insufficient liquid supply, impact of liquid injection and recovery ports, and failure of lithography equipment components to work normally, etc. Achieve the effect of reducing the possibility of leakage and inhibiting air bubble entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

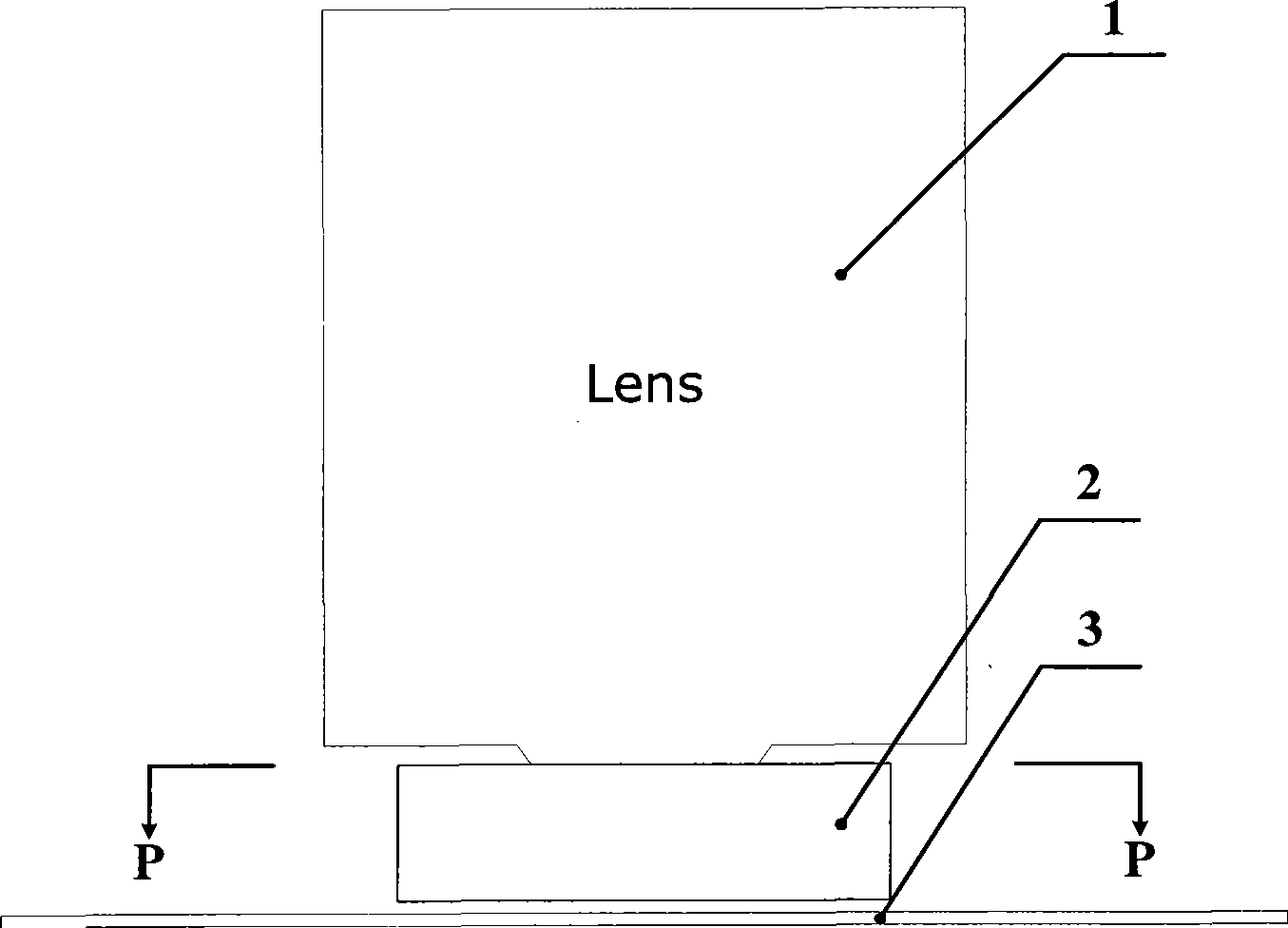

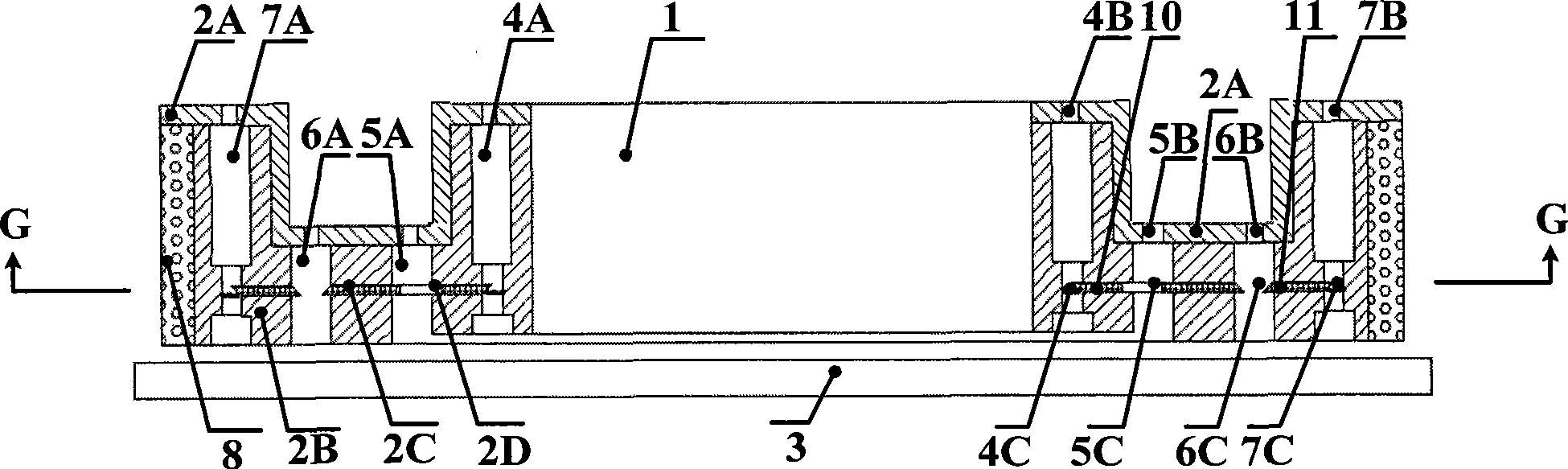

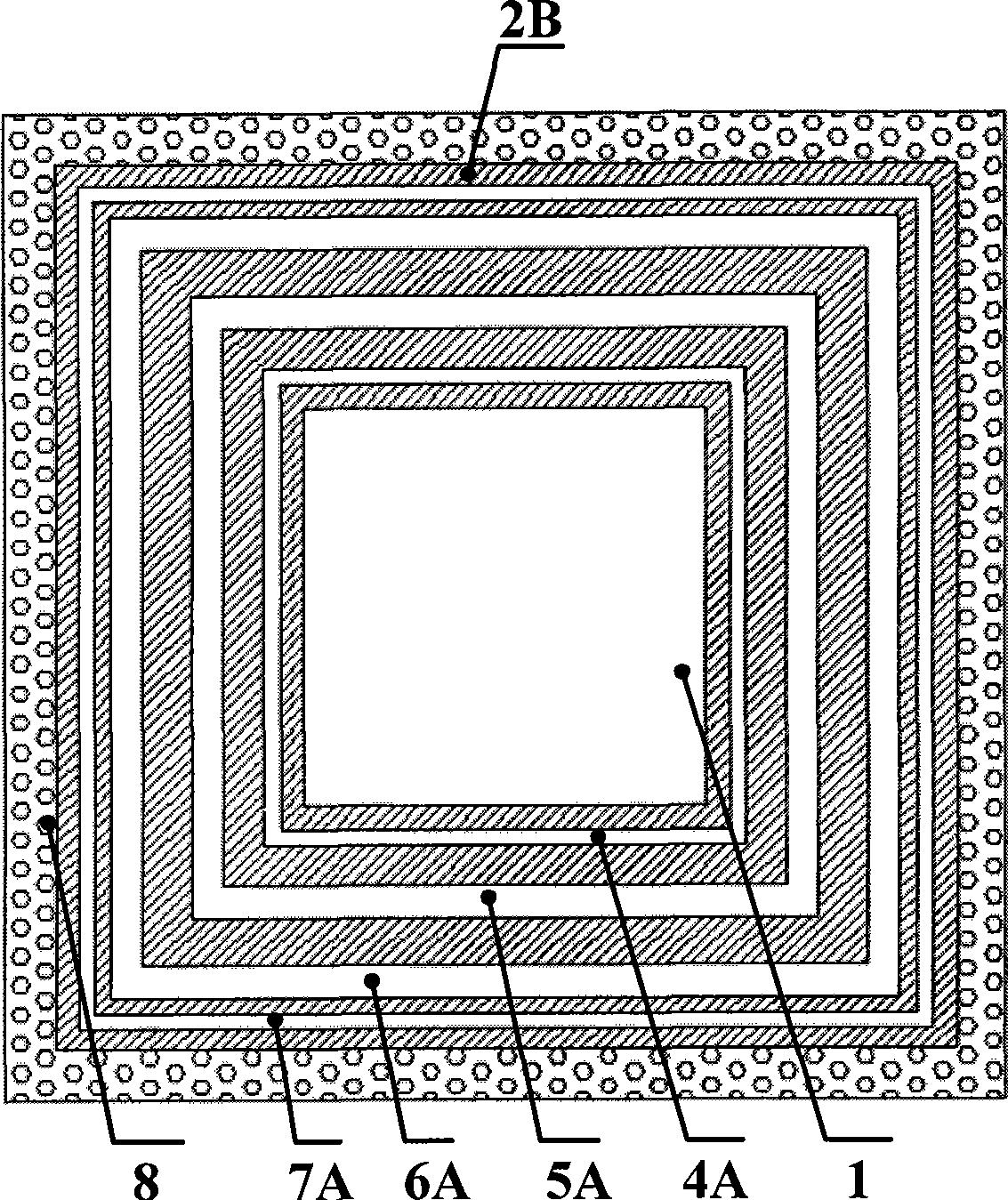

[0029] Such as figure 1 , figure 2 , image 3 Shown is the flow field stabilizing device 2 provided between the projection lens group 1 and the substrate 3 to be exposed according to the present invention. The flow field stabilization device 2 is composed of a pipeline connection body 2A, a main structure 2B, an adaptive slider group 2C, and a slider group channel 2D; wherein:

[0030] 1) Pipeline connector 2A: from the center to the outside, there are four equally distributed inner isolation chambers connected to the atmosphere through hole 4B, the liquid injection port 5B, the recovery port 6B and the outer isolation chamber connected to the atmosphere through hole 7B;

[0031] 2) Main structure 2B: There are four symmetrical rectangular columnar cavities in sequence from the center to the outside, which are the inner isolation cavity 4A, the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com