System and method for recognizing problems of micro-actuator piezoelectric elements

A micro-actuator and piezoelectric element technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, instruments, etc., can solve problems such as inability to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

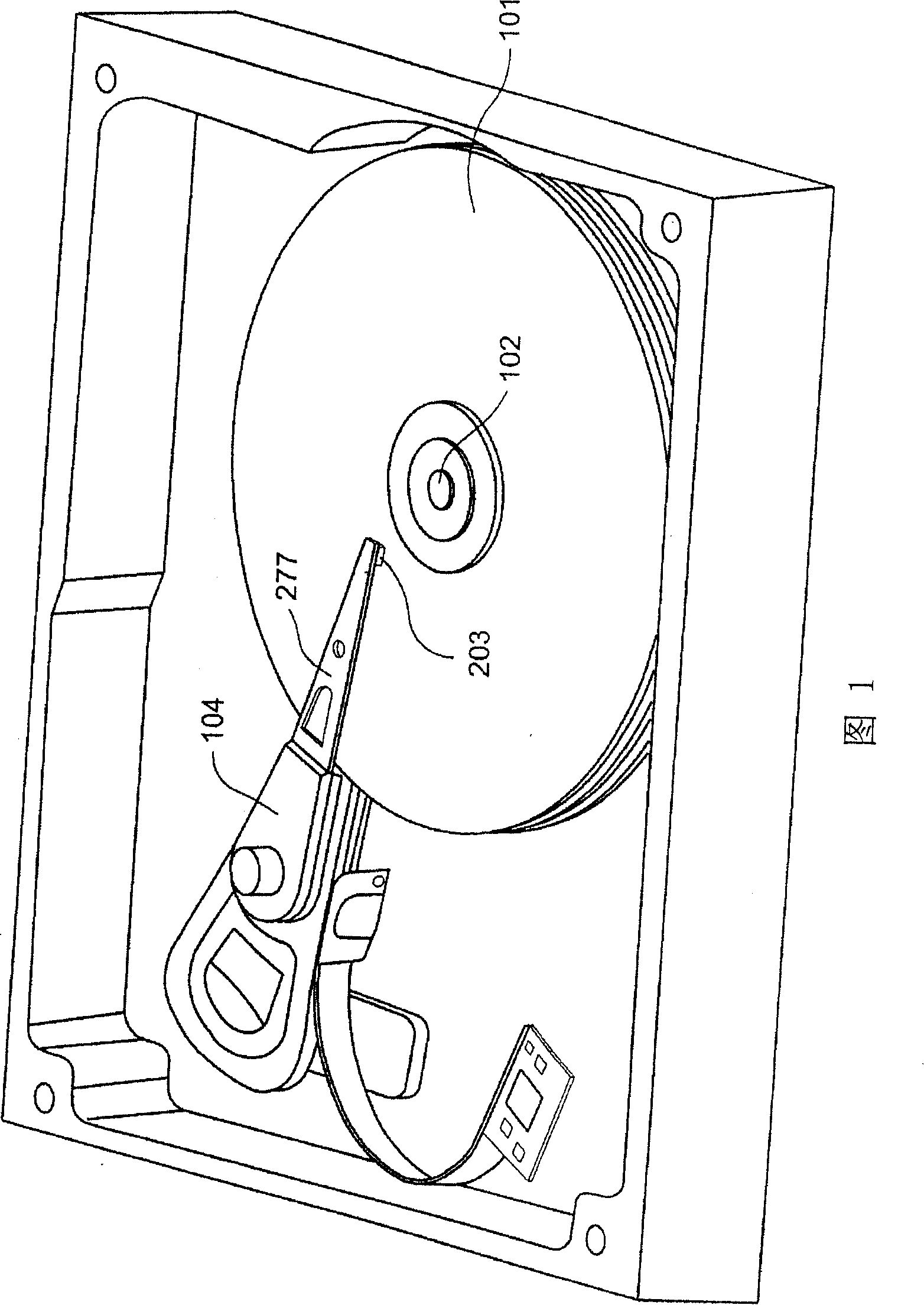

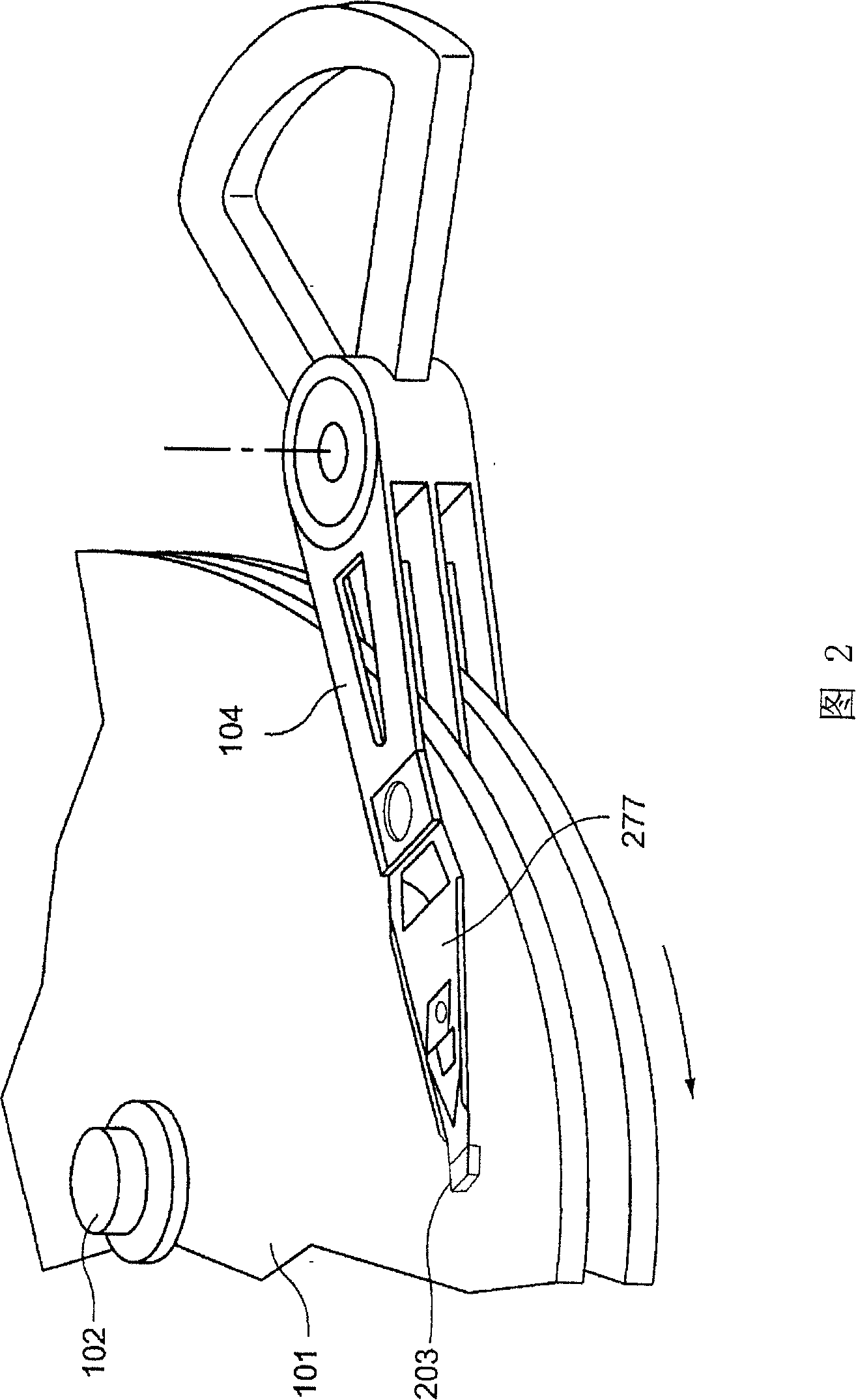

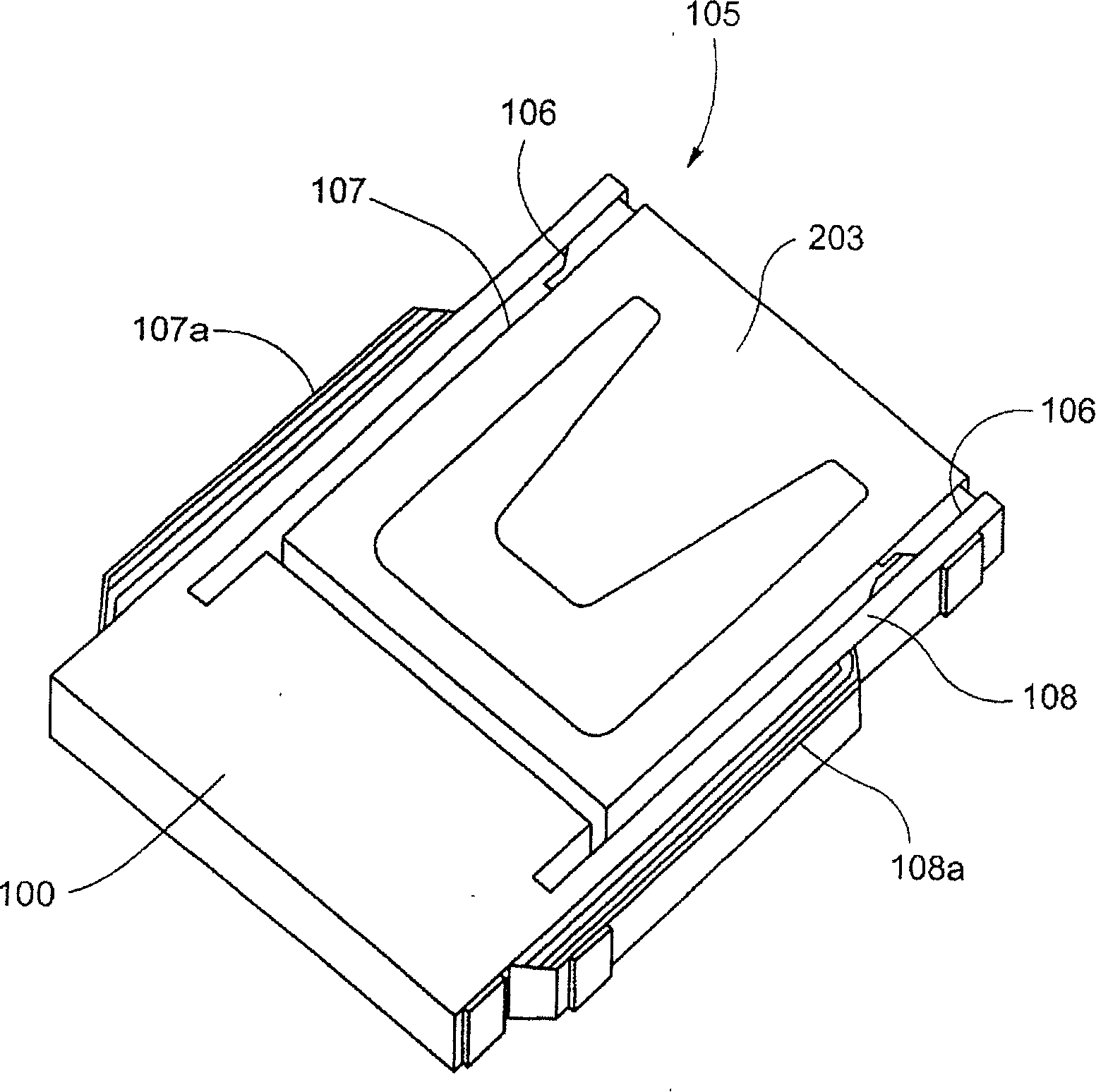

[0038] Several embodiments of the invention provide techniques for identifying problems (eg, microcracks, deformation, etc.) that exist within the piezoelectric element of a microactuator. The reference cell and the test cell can be induced to vibrate by applying a voltage (eg, a sinusoidal voltage) across the reference cell. Whether there is a problem with the test unit can be determined by comparing (eg, with a processor) corresponding resonance characteristics (eg, frequency, amplitude, phase, etc.). The reference unit may include a HGA or HSA of a hard disk drive. The testing device may comprise corresponding components for detection. This technique enables detection of piezoelectric element problems when each microactuator has only one piezoelectric element.

[0039] Figure 4a-4b An exemplary source device 401 of the test system according to several embodiments of the present invention is shown; Fig. 4c-4d shows an exemplary receiving device of the test system accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com