Power battery management system with control and protection function and method thereof

A power battery and protection function technology, which is applied in the field of power battery management system integrating control and protection functions, can solve the problems of inability to accurately describe, consume the decision time of the controller and the driver, and the judgment conditions cannot be clearly defined, etc. Achieve the effect of high warning/alarm accuracy and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention are described in detail below.

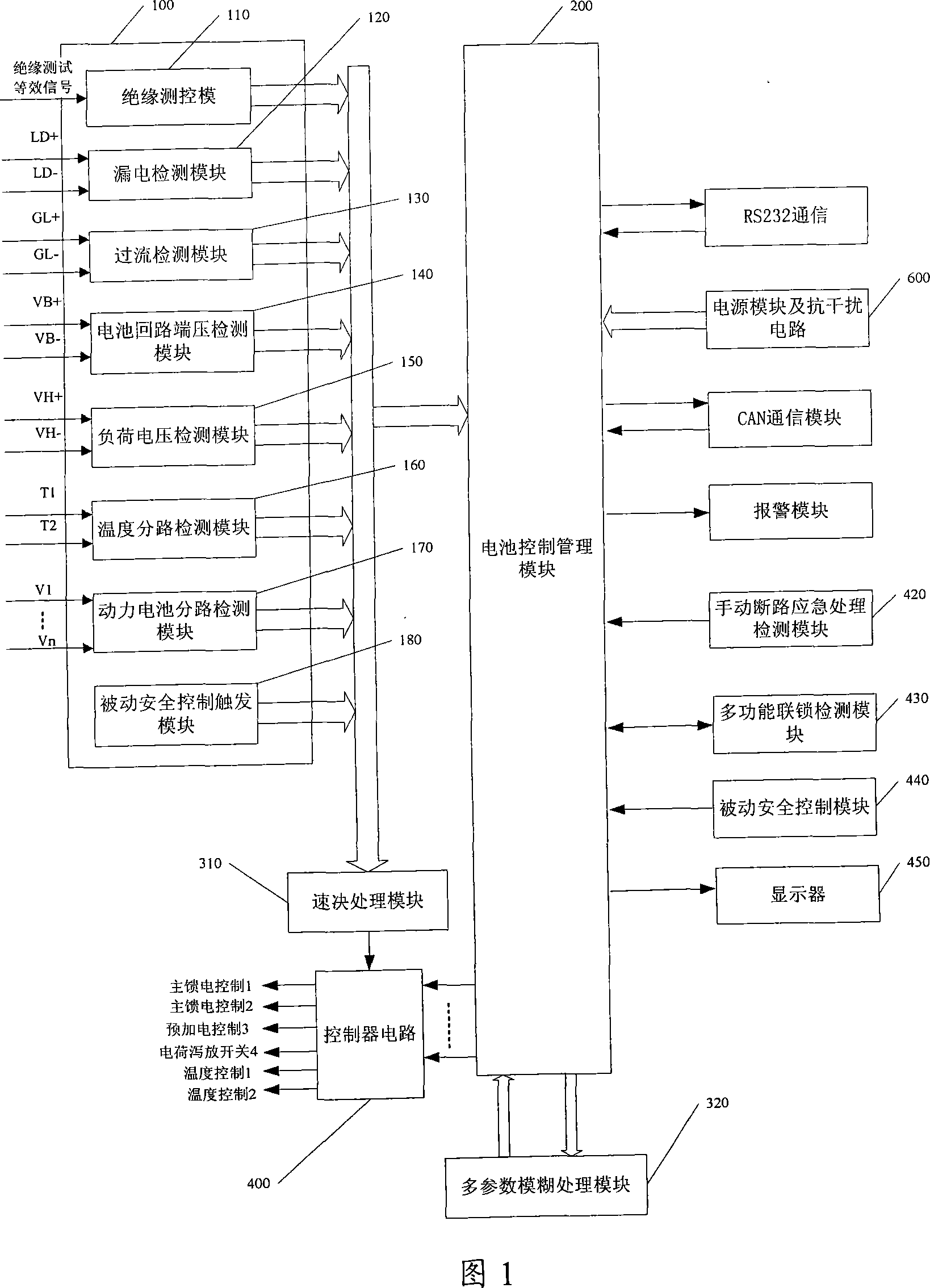

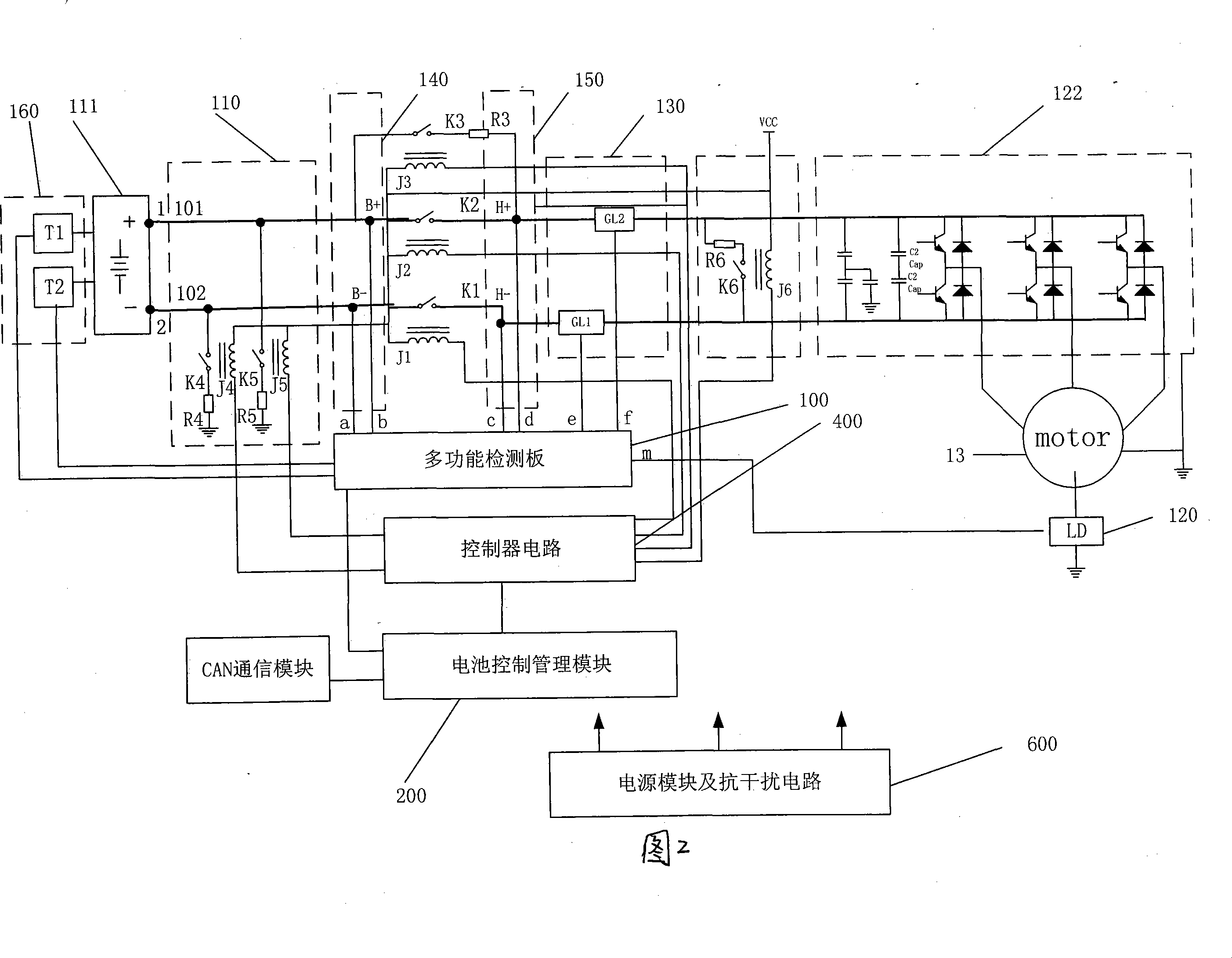

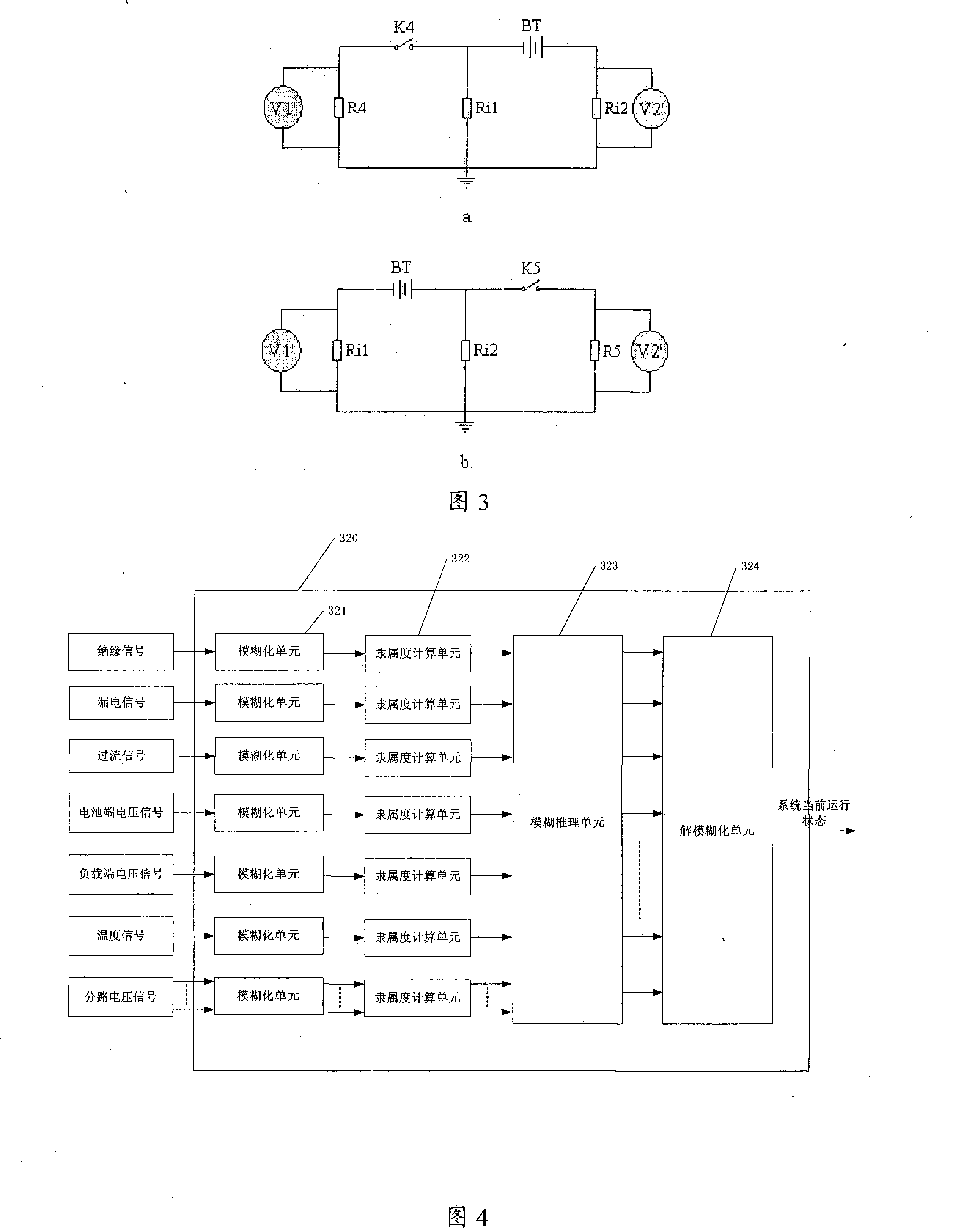

[0045] As shown in Figure 1, the present invention provides a power battery management system integrating control and protection functions, which can be applied to electric vehicles, and includes a multi-functional detection board 100, which is used to detect high-voltage battery packs and their power supply, The abnormal operation signal of the power system; it also includes: battery control management module 200, multi-parameter fuzzy processing module 320 and controller circuit 400; multi-parameter fuzzy processing module 320 is used to sequentially perform Fuzzification processing, membership degree calculation, fuzzy reasoning classification and defuzzification processing process, and judge the current running state of the automobile system (the automobile system includes the power battery management system of the present invention, the high-voltage battery pack and its power supply and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com