Automatic sequence boxing assembly line of high speed special-shaped bottle

A technology of automatic sequence and special-shaped bottles, applied in the direction of automatic packaging control, packaging, packaging bottles, etc., can solve the problems of no suitable special-shaped bottles, no high-speed, sequential packing, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

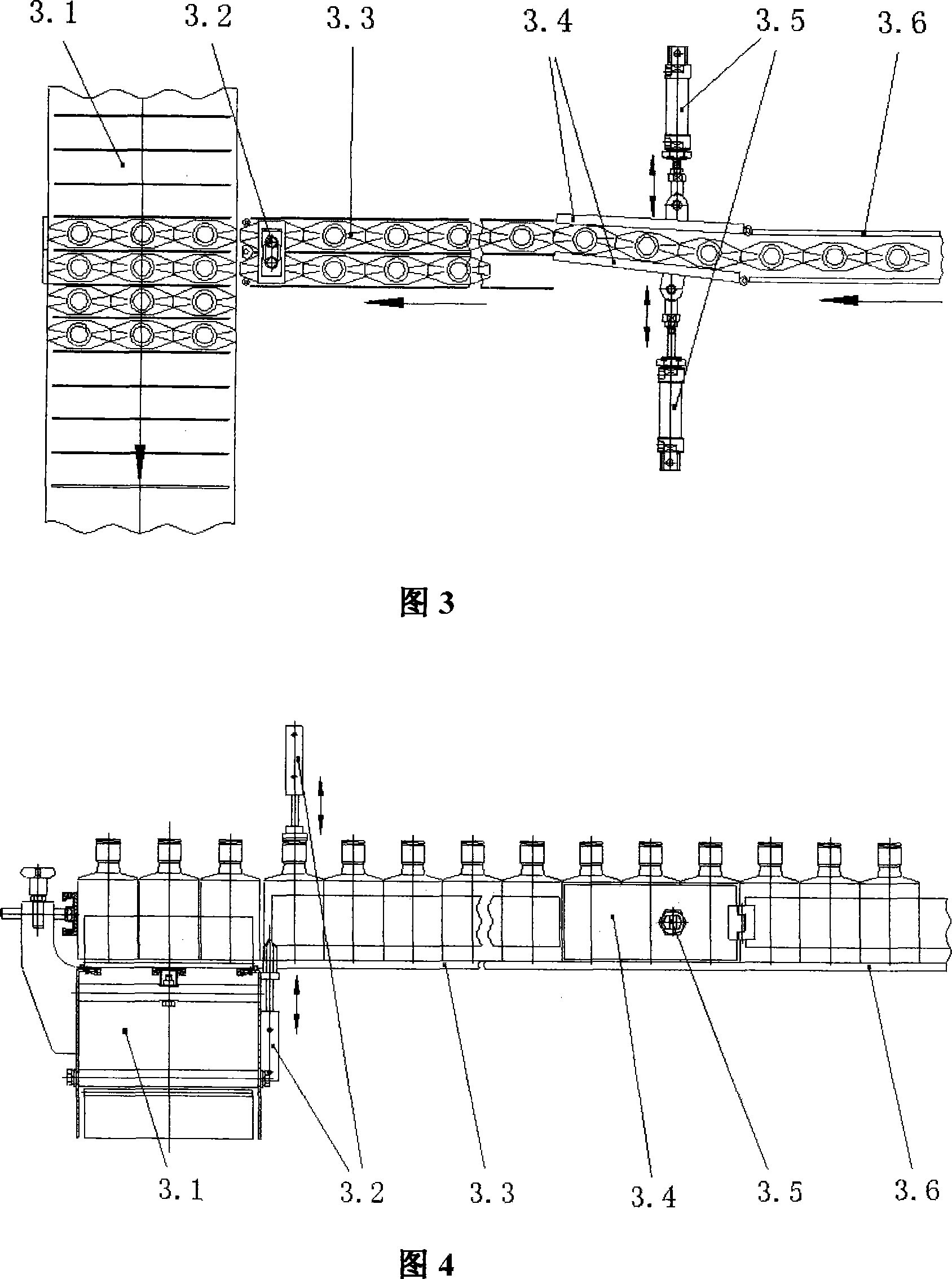

[0022] Explanation of labels in Fig. 3: multi-row bottle conveying chainway 3.1, bottle blocking cylinder 3.2, double row bottle conveying chainway 3.3, swing bottle separating plate 3.4, bottle separating cylinder 3.5, single row bottle conveying chainway 3.6.

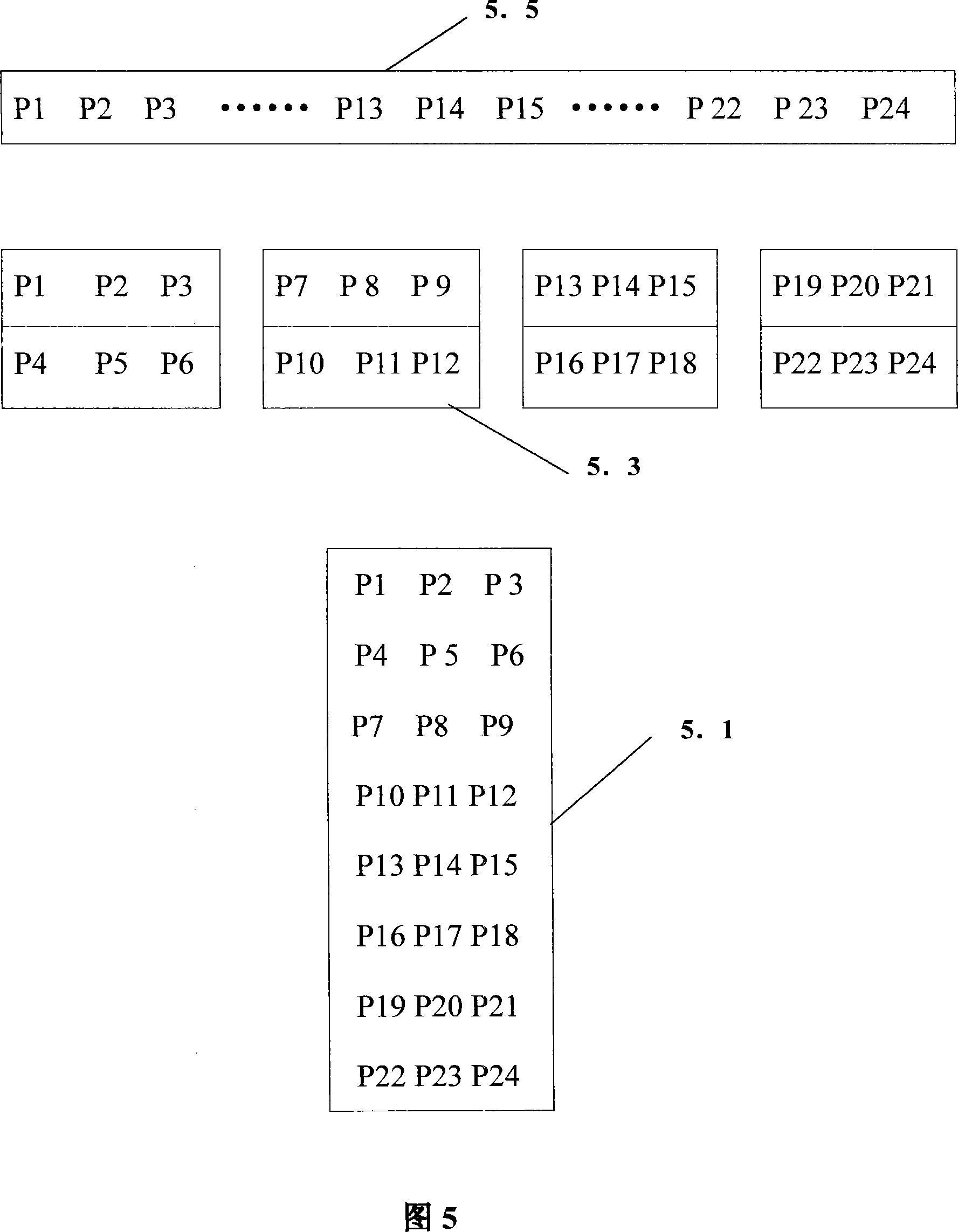

[0023] Explanation of the labels in Fig. 5: the sequence of single-row bottles is 5.5, the sequence of double-row bottles is 5.3, and the sequence of three-row bottles is 5.1.

[0024] Explanation of the labels in Fig. 6: collet 6.1, fixed shaft 6.2, swing shaft 6.3, connecting shaft 6.4, connecting rod 6.5, mounting seat 6.6, pull rod 6.7, pneumatic slide plate 6.8, cylinder 6.9.

[0025] The high-speed special-shaped bottle automatic sequential packing production line of the embodiment of the present invention is composed of a fully automatic case unpacking machine, a roller case conveying machine, an automatic sequential case packing machine and an automatic case sealing machine con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com