Full-automatic shaping packing machine of bag-in-bag

A bag-in-bag, fully automatic technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of easy fatigue of workers, high labor intensity, low speed and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

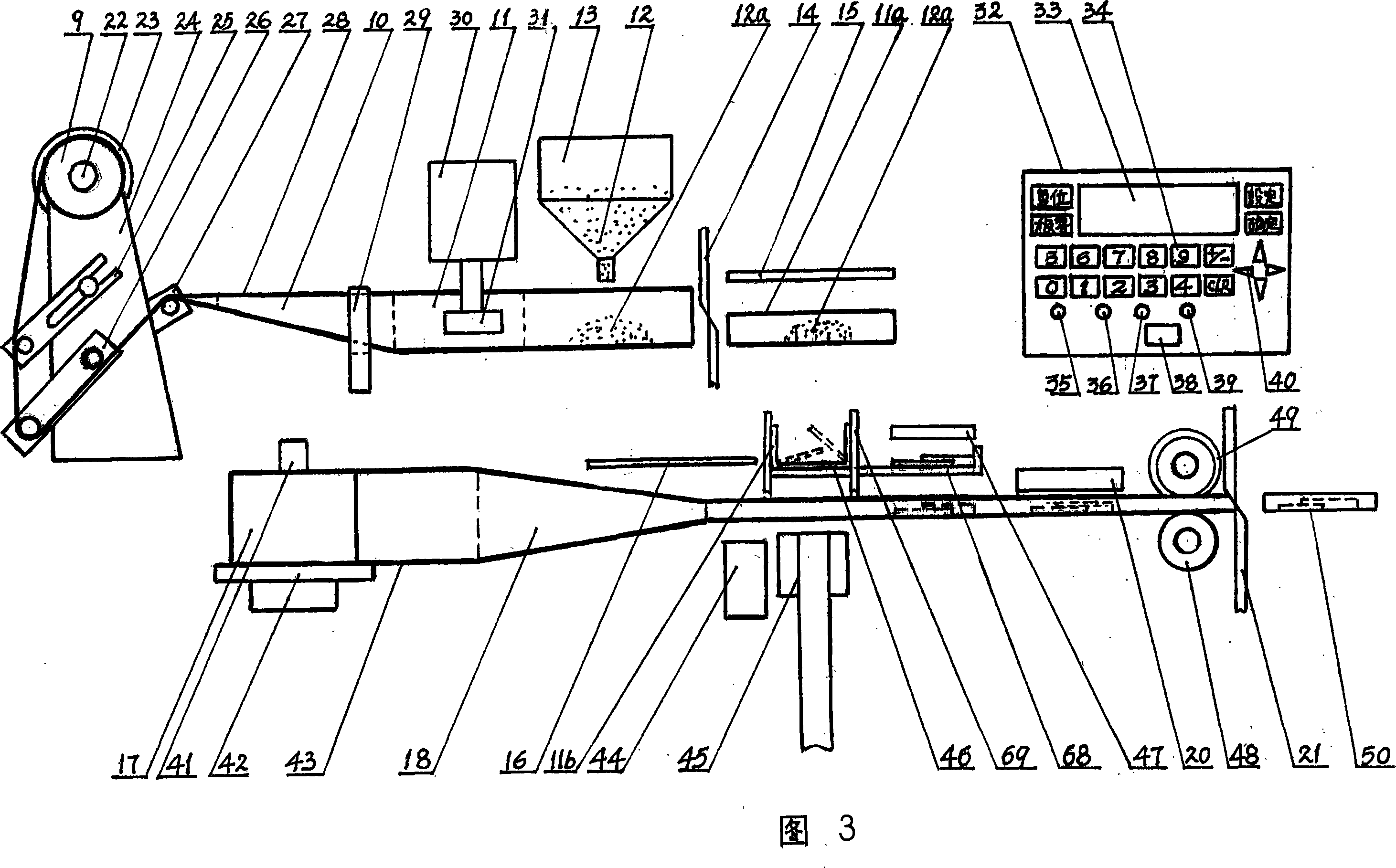

[0079] The utility model will be further described below in conjunction with accompanying drawings and embodiments.

[0080] The present embodiment is made up of mechanical operating system, mechanical transmission system and manipulation system.

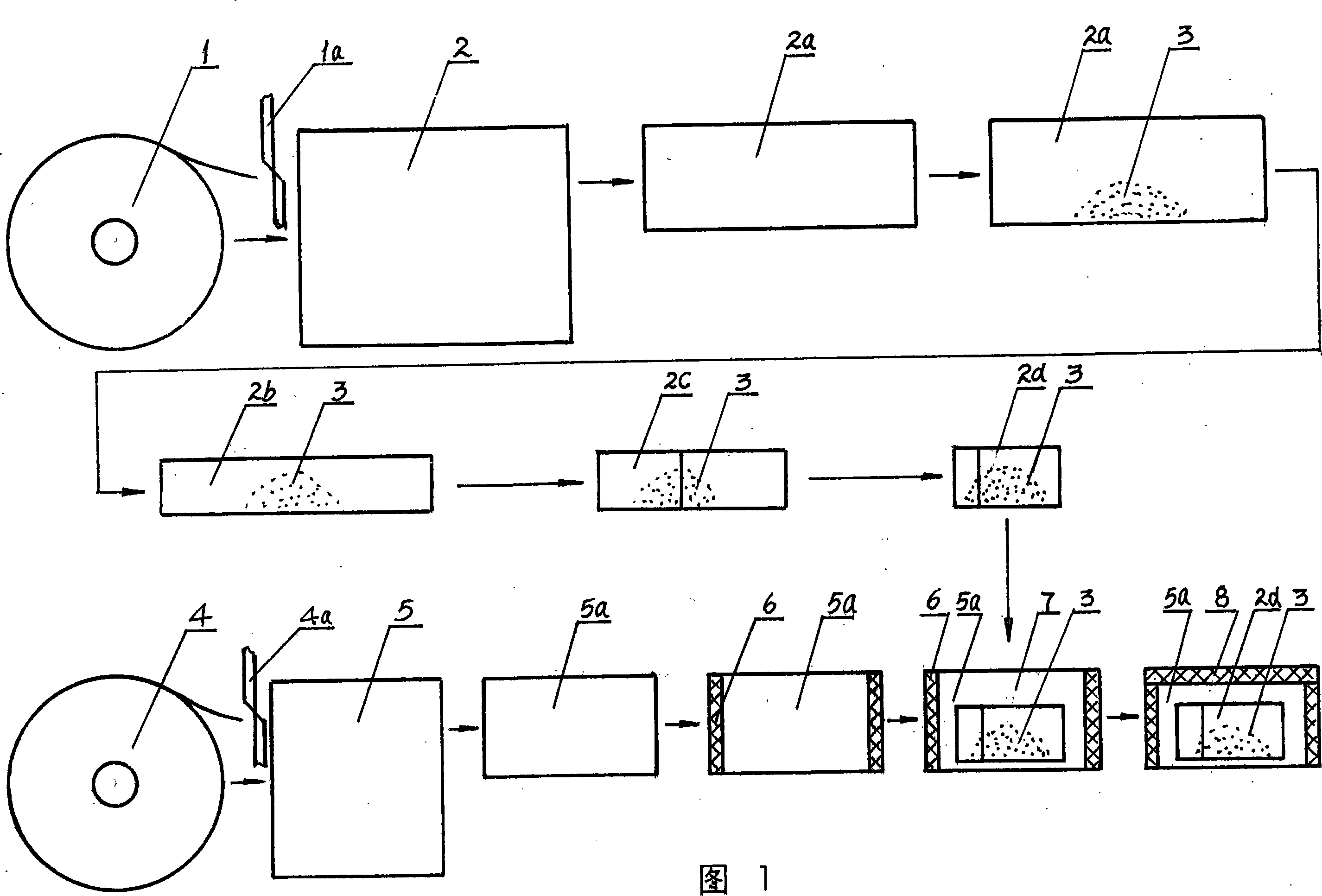

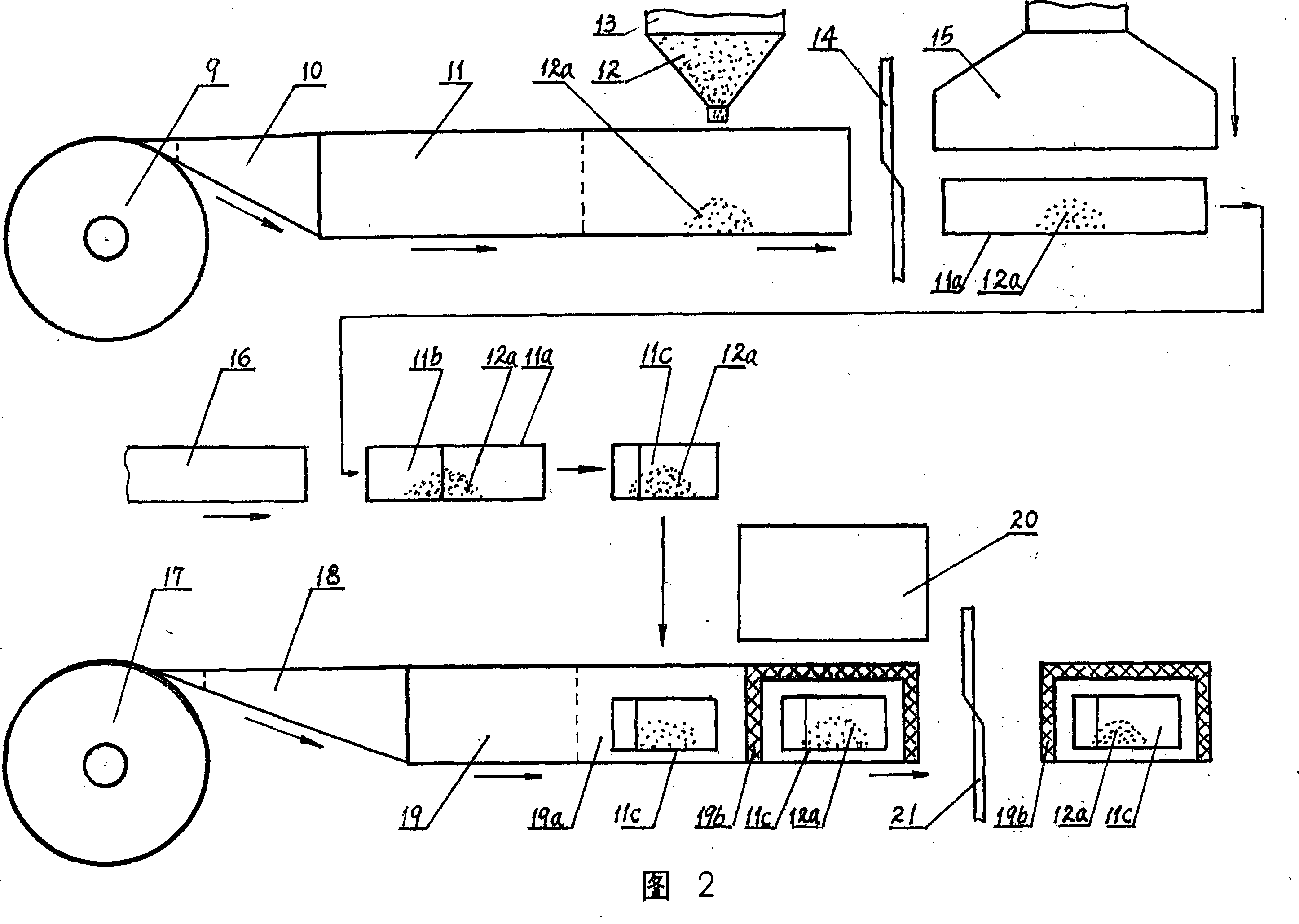

[0081] The mechanical operating system consists of three parts: the inner bag forming part, the outer bag forming part and the bag-in-synthetic double-packaging part.

[0082] The inner bag forming part is an inner bag roll material 9 installed on the upper part of the cylindrical support 24 fixed on the cabinet panel 57, and an inner bag feeding motor 23 and an inner bag feeding shaft 22 are installed on the upper part of the cylindrical support 24. The bag coil material 9 is arranged on the coil material shaft 22, and the feed motor 23 drives the coil material shaft 22 to rotate, so that the inner bag coil material 9 is fed. Cylindrical support 24 is also equipped with adjustable support 25, so that adjust the degree of tightness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com