Compositions for humidity proof heat sealer having low specific gravity

A technology of heat sealant and composition, applied in sealing devices, adhesives, transportation and packaging, etc., can solve the problems of reducing fuel efficiency and high specific gravity of sealants, and achieve the effect of improving fuel efficiency

Inactive Publication Date: 2009-10-14

HYUNDAI MOTOR CO LTD

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] In addition, conventional sealants have a very high specific gravity of about 1.7, and about 7-8 kg of sealant is used to manufacture a car, which increases the overall weight of the car, which reduces fuel efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-6

[0052] A low specific gravity anti-humidity sealant composition of the present invention was prepared. The components listed in Table 1 below were mixed in a batch type kneader commonly used by those skilled in the related art. After mixing and dispersing the sealant composition at 25° C. to 35° C., followed by vacuum degassing, the sealant composition is prepared with a viscosity of 150,000 to 250,000 cps (centistokes).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to humidity-proof heat sealer compositions having low specific gravity, which comprise a polyvinyl chloride resin, a filler, a moisture absorbent, a plasticizer, an adhesion promoter, an additive, and so forth, for use in automotive steel sheet joints or outside panel joints. When compared with conventional sealer compositions, the present compositions provide improved humidity resistance, as well as improved fuel efficiency.

Description

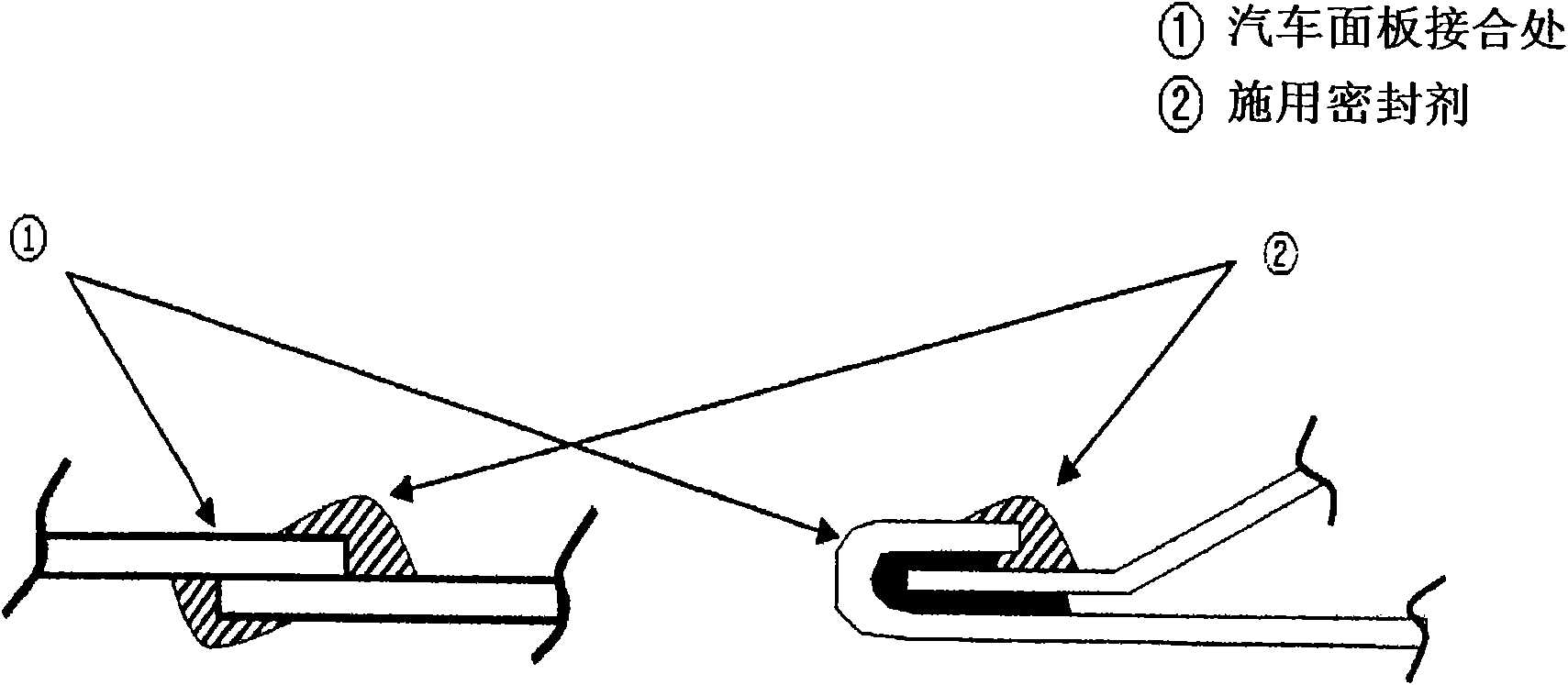

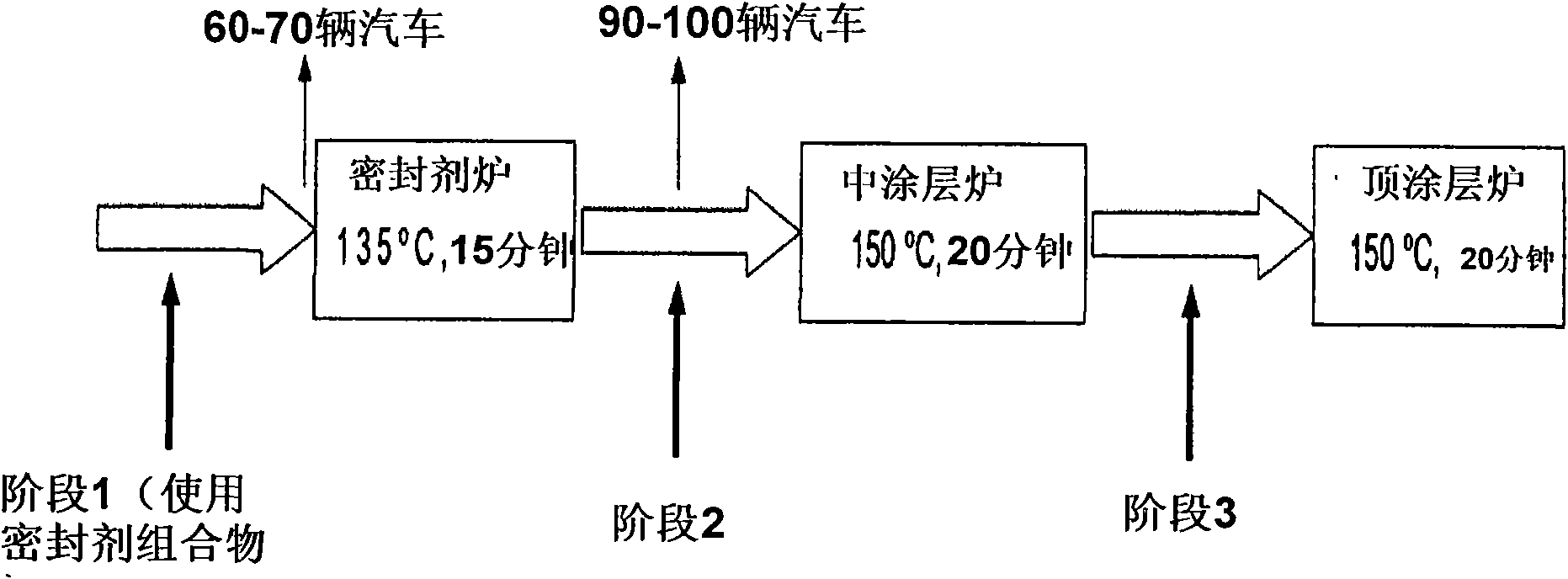

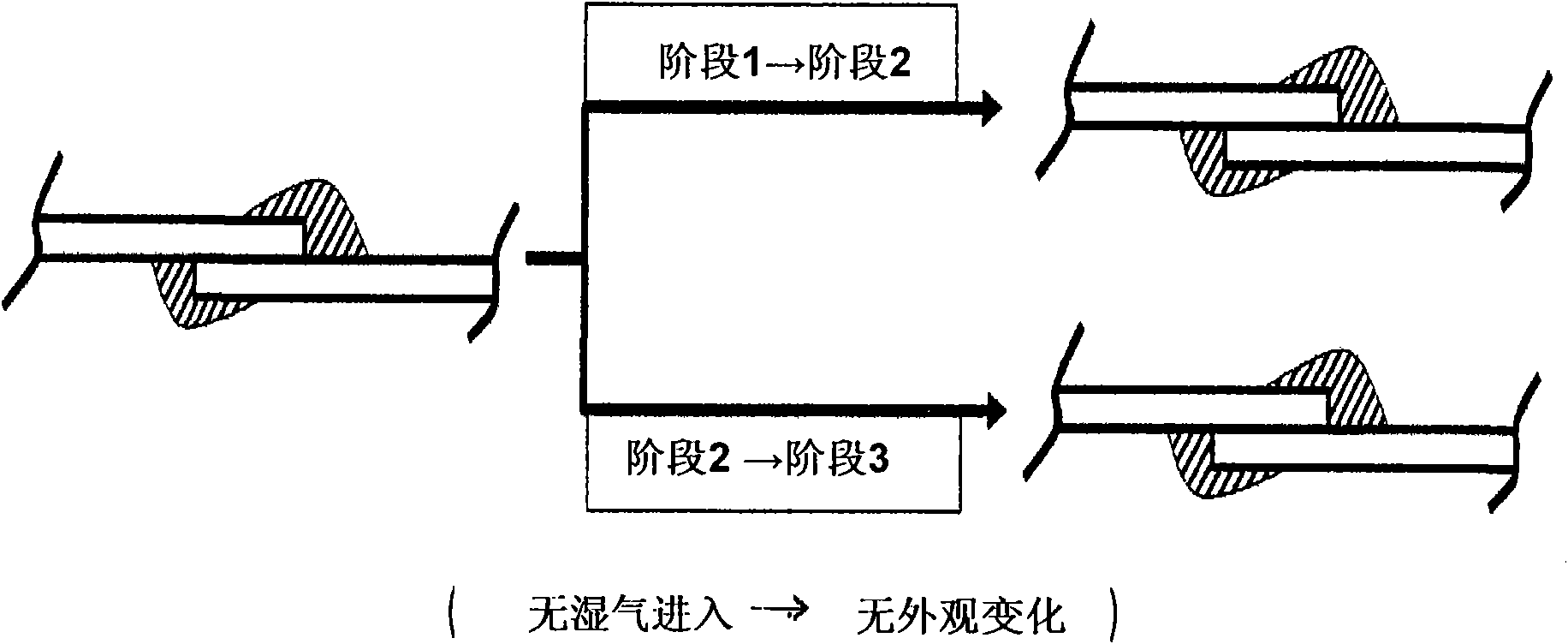

[0001] Cross References to Related Applications [0002] This application claims priority under 35 U.S.C. §119(a) to Korean Patent Application No. 10-2008-0033365 filed Apr. 10, 2008, which is hereby incorporated by reference in its entirety. field of invention [0003] The invention relates to a low specific gravity humidity proof heat sealer composition, which includes polyvinyl chloride resin, filler, hygroscopic agent, plasticizer, tackifier (adhesionpromoter), additives and the like. Background technique [0004] Such as figure 1 As shown, in the manufacturing process of automobiles, a sealer is applied to the steel plate joints of automobiles before painting to prevent water leakage, rust and noise. [0005] For conventional sealants, as disclosed in Korean Patent Application No. 2001-41257, such as figure 2 As shown, they are cured under the action of heat while passing through an oven for bottom, middle and top coating methods. [0006] During long weekends, holi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K3/10C09J127/06C08L27/06C08K13/06C08K7/22C08K9/10C08K3/22

CPCC09K2200/0635C09K2200/0239C09K3/10C09K2200/0441C09K3/1006C09K2003/1081

Inventor 崔圭生

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com