Cutting separation method for high furnace base under production state

A technology of production state and separation method, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problem of long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

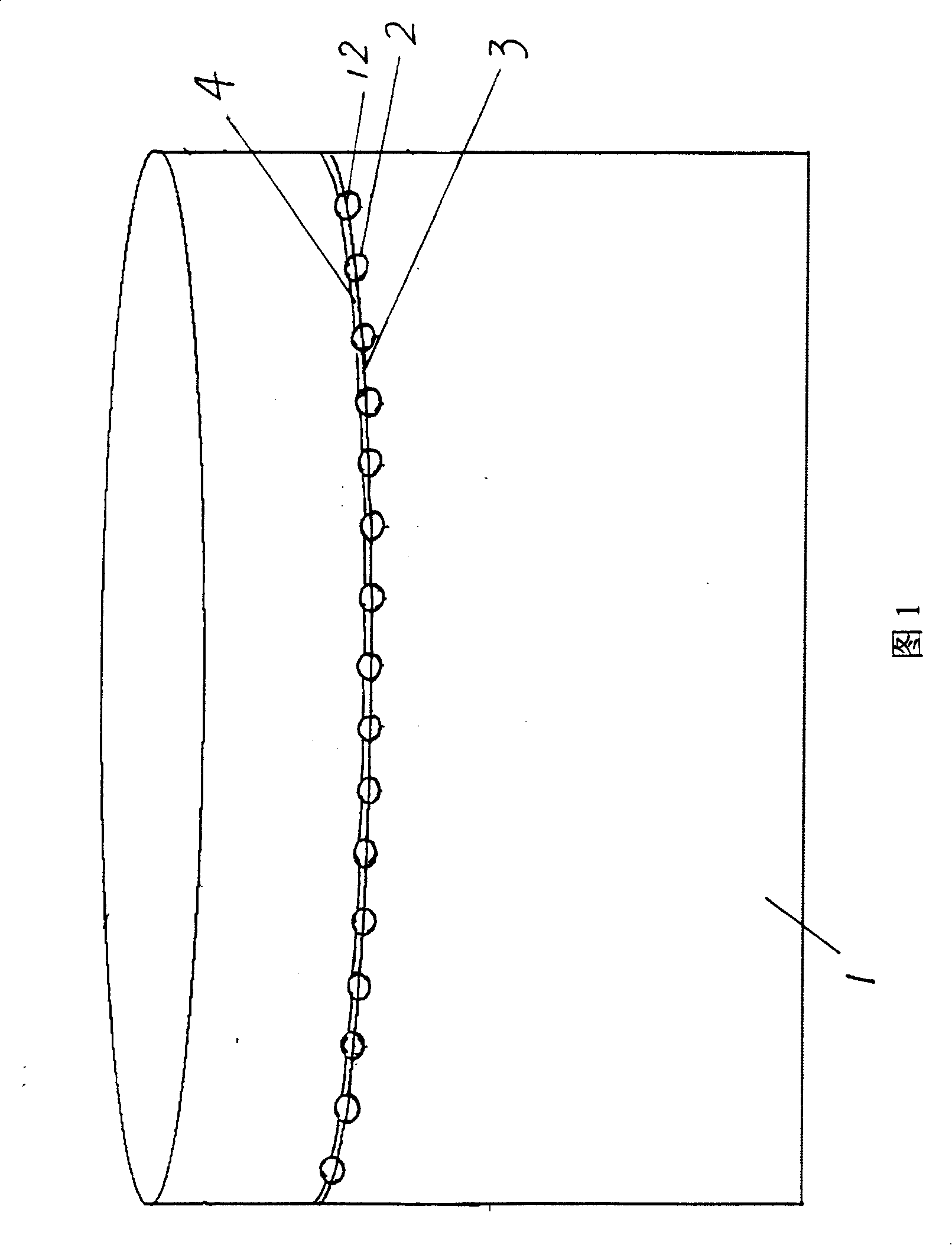

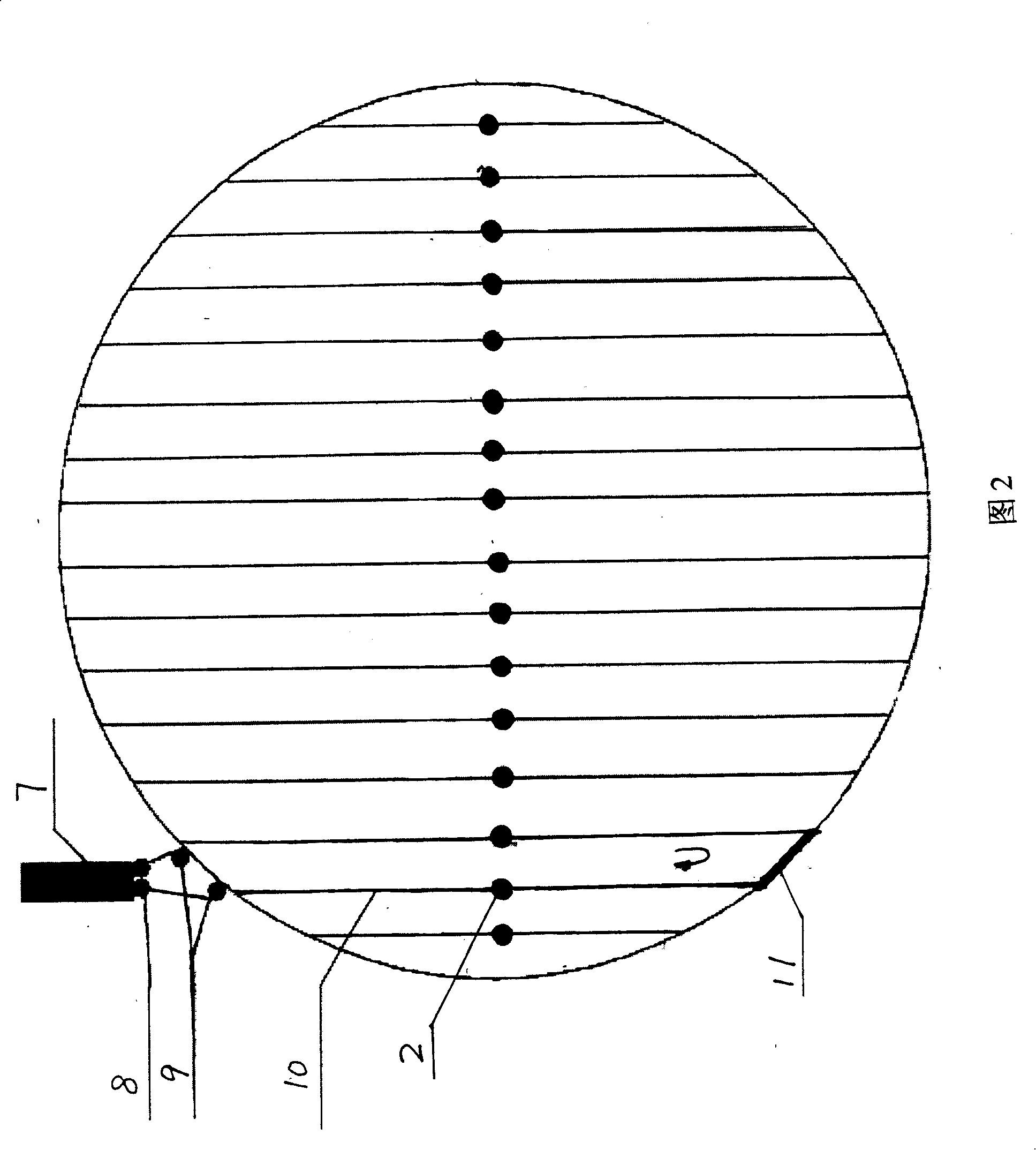

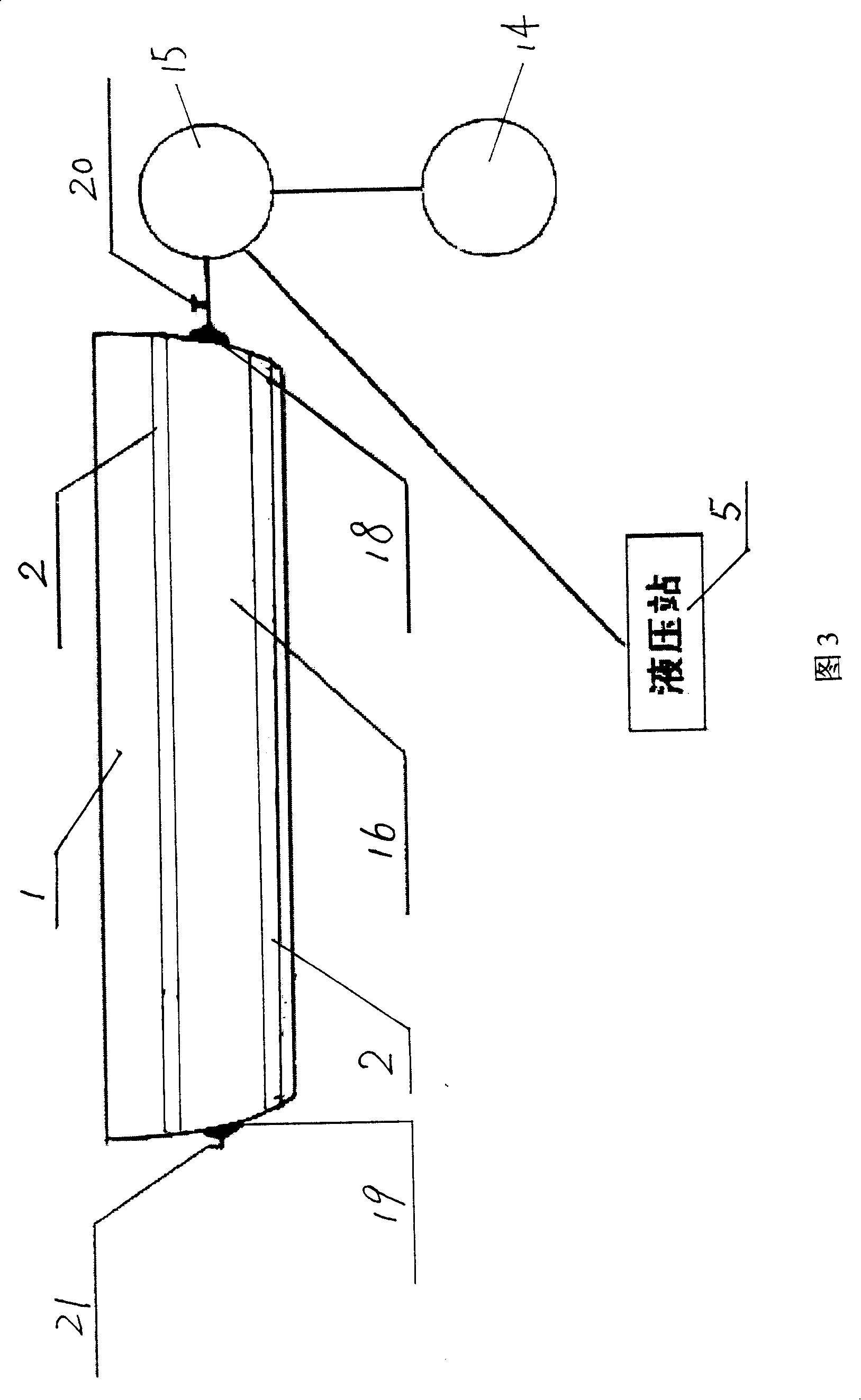

[0012] The method for cutting and separating the blast furnace foundation in the production state includes the following steps: A. Drilling. A plurality of parallel horizontal perforations 2 are arranged side by side in the middle and upper part of the blast furnace foundation 1. The diameter of the perforations 2 is 89mm-108mm. The distance between adjacent perforations 2 is not greater than 1.3m, and the distance between the centers of two perforations on the edge and the edge is not greater than 0.8m; B. Cutting, select the cutting unit, select two adjacent perforations 2, and use cutting equipment to The blast furnace foundation is horizontally cut between two adjacent perforations to form a cutting seam 3 with a thickness of 10mm to 15mm, which is connected to the above two adjacent perforations 2; Pressure isolation layer 4, the thickness of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com