Guide bar shogging mechanism

The invention relates to a technology of bar traversing and moving device, which is applied in textile and papermaking, knitting, warp knitting and other directions, and can solve the problems of increased meshing gap between screw and nut, inaccurate bar traverse, and unfavorable maintenance. Achieve the effect of smooth motion, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

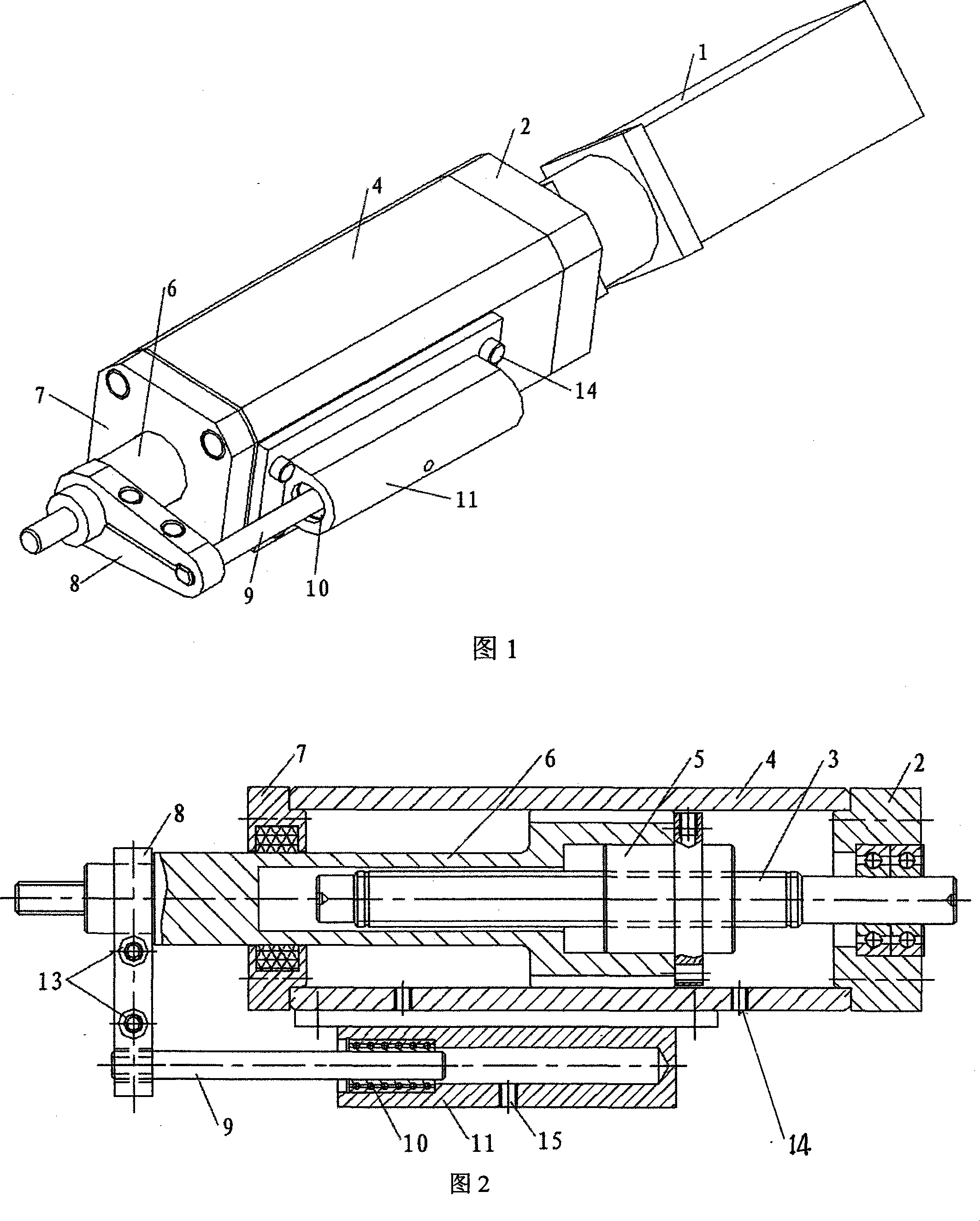

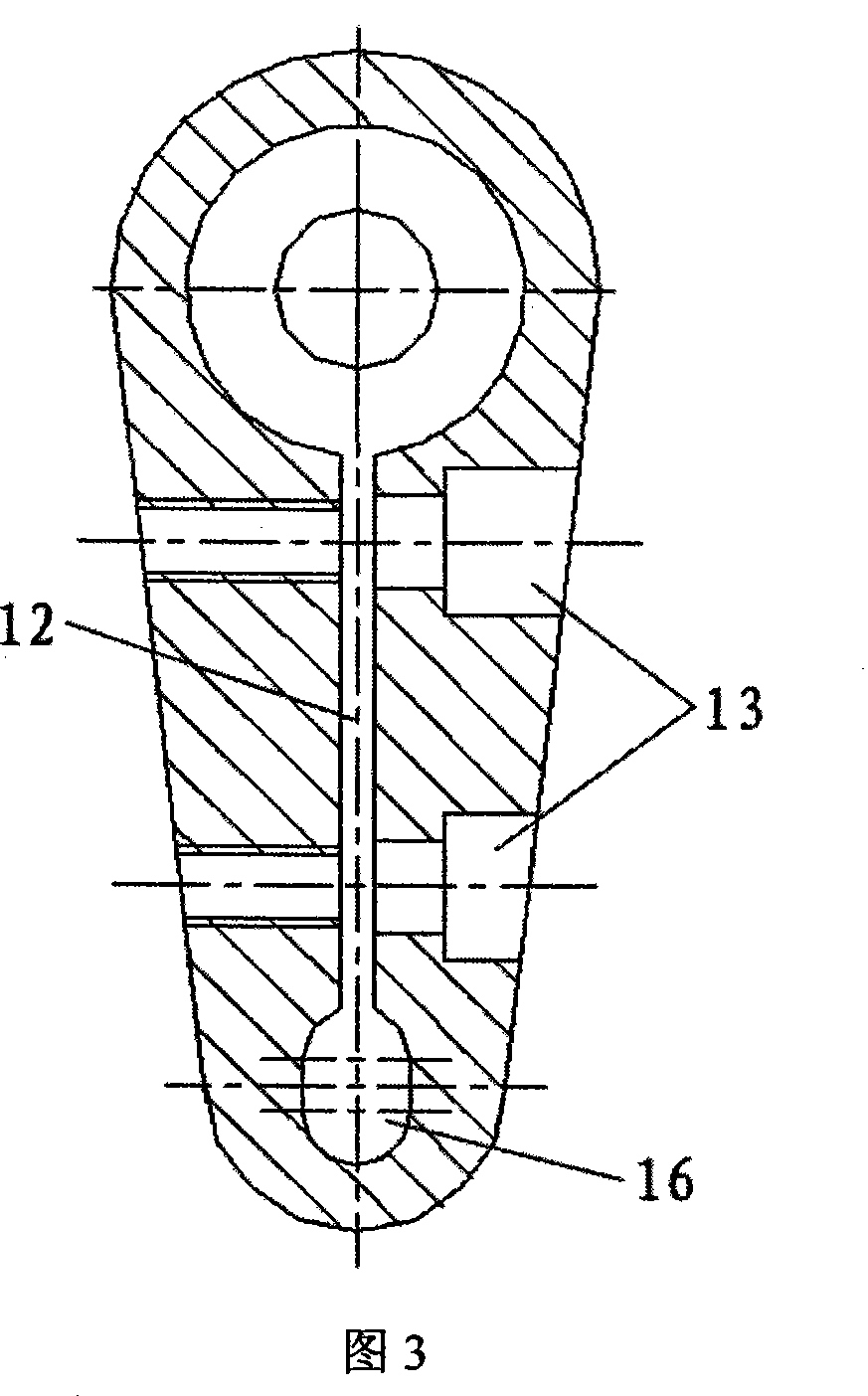

[0015] The accompanying drawings disclose two specific embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

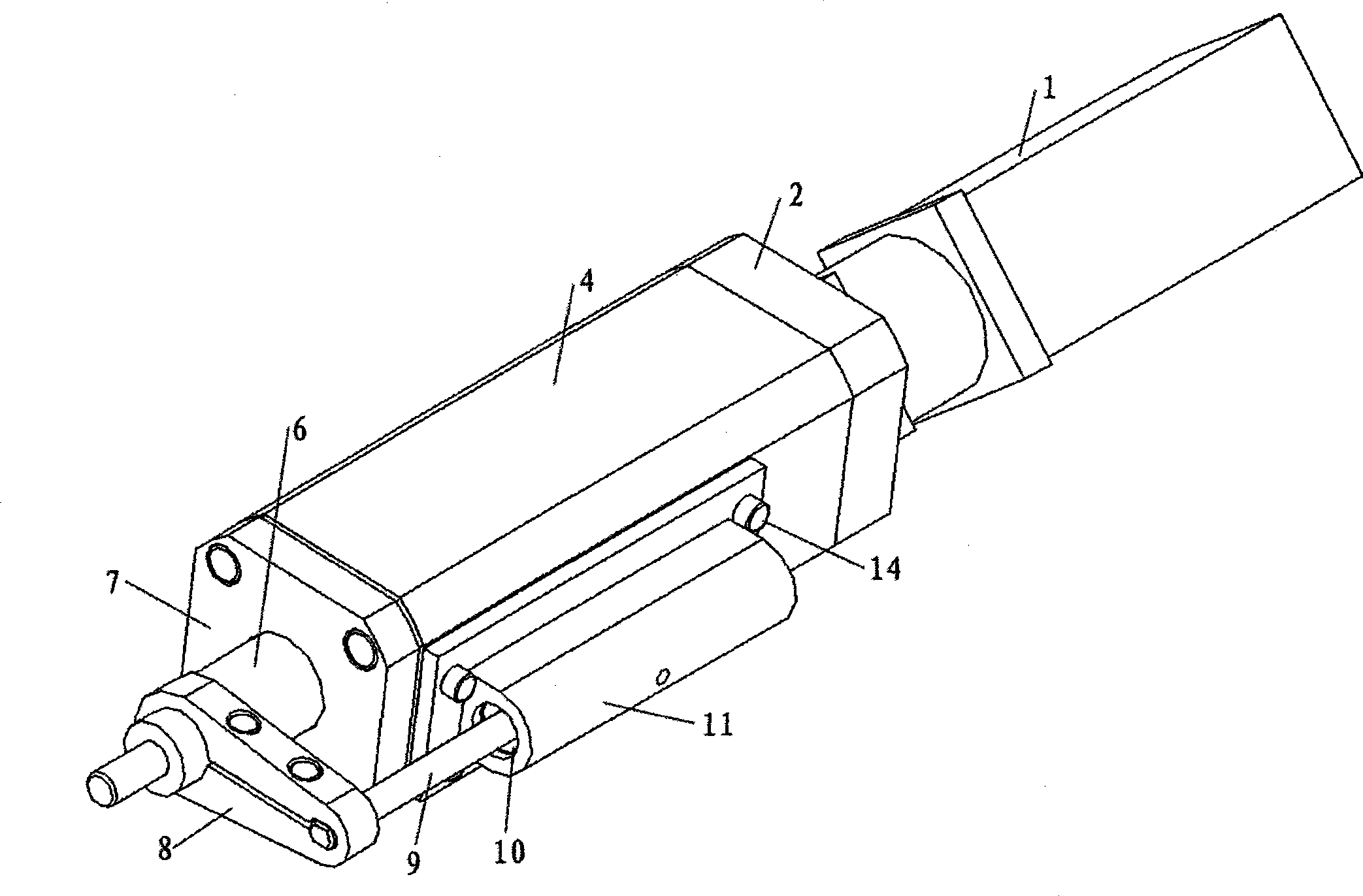

[0016] See the accompanying drawings, 1 in the figure is the servo motor, 2 is the bearing housing, 3 is the ball screw, 4 is the sleeve, 5 is the ball nut, 6 is the push rod shaft, 7 is the end cover, 8 is the connecting rod, 9 Is telescopic shaft, and 10 is linear bearing, and 11 is supporting body, and 12 is connected seam, and 13 is screw hole, and 14 is screw, and 15 is oil hole, and 16 is connecting rod hole.

[0017] The bar traversing device of the present invention includes a servo motor 1 and a mover, the mover is composed of a main mover and an auxiliary mover, the auxiliary mover is fixed in parallel on the outside of the main mover, and the servo motor 1 is installed On the bearing seat 2 of the device, the telescopic shaft 9 of the auxiliary mover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com