High-temperature solar heat pipe receivers

A technology of solar heat pipes and high temperature heat pipes, which is applied in the directions of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of affecting the efficiency of heat absorption, limiting, reducing the thermal efficiency of receivers, etc., and achieves the advantages of convenient processing and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

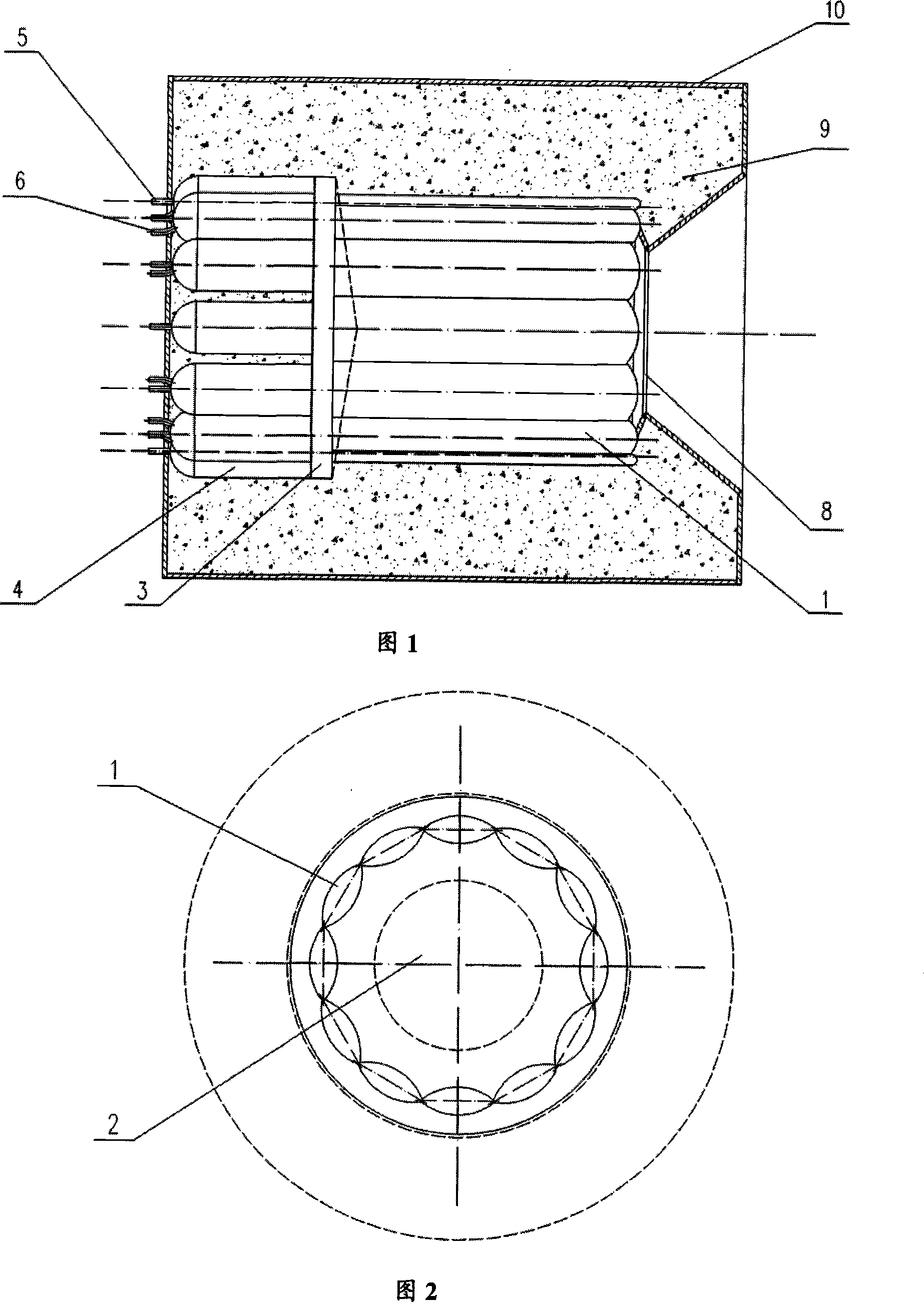

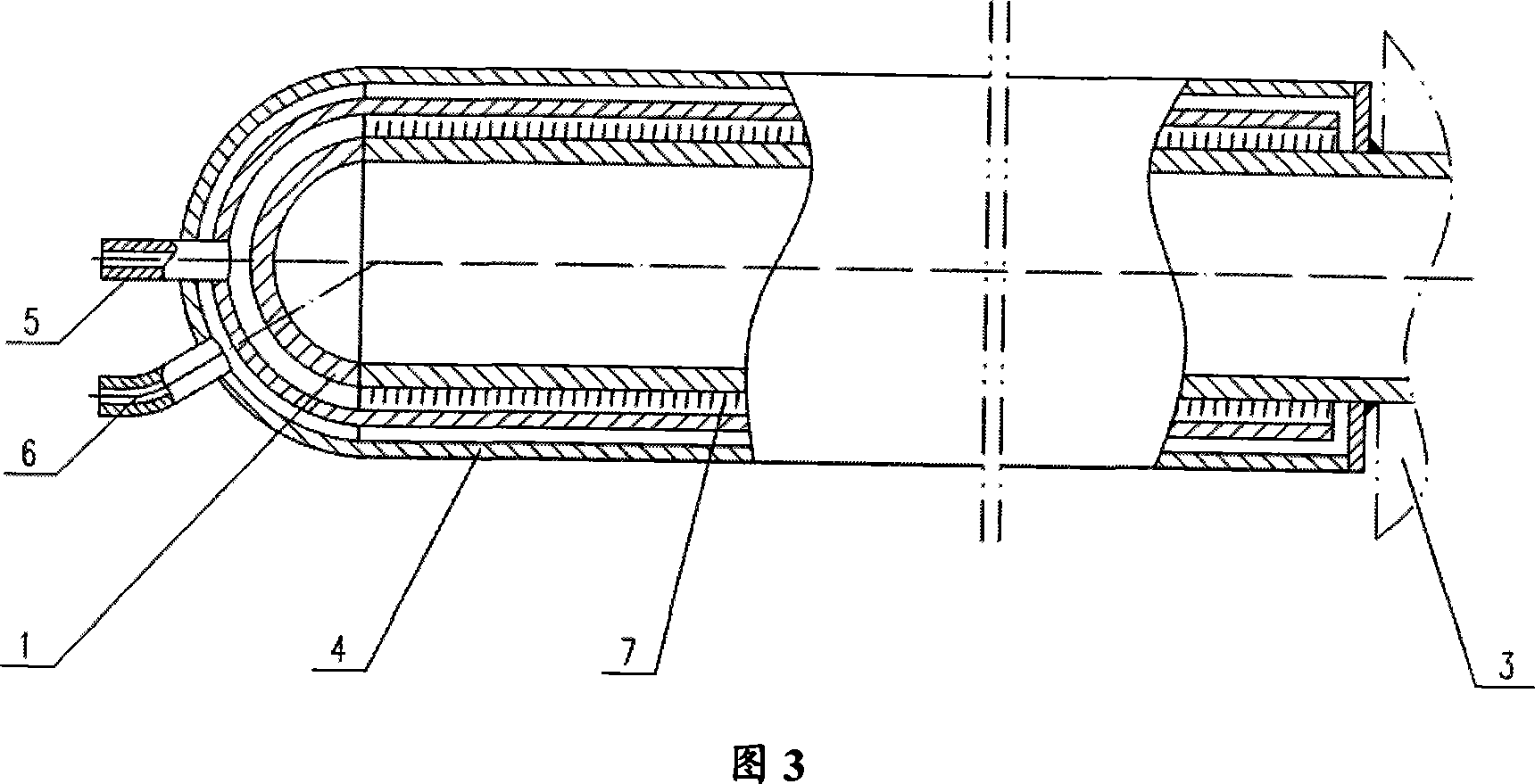

[0024] As shown in Figure 1, Figure 2, and Figure 3, the high-temperature solar heat pipe receiver structure for dish solar thermal power generation includes several special-shaped high-temperature heat pipes 1, and a heat-absorbing cavity 2 formed by high-temperature heat pipes 1 evenly distributed in the middle, The high-temperature heat pipe 1 is divided into a ceramic cone 3 of a heat absorbing section and a heat releasing section, a sleeve 4 for heat exchange of a working fluid, a working fluid inlet pipe 5 and a working fluid outlet pipe 6 . The part of the high-temperature heat pipe 1 in the casing 4 is cylindrical, while the part in the heat-absorbing cavity is processed into a shuttle shape and connected in pairs. Spiral fins 7 are installed on the outer wall of the heat release section of the high-temperature heat pipe 1 in the casing 4 to enhance the heat exchange of the fluid. The opening of the heat-absorbing cavity is provided with a lighting hole 8 made of ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com