H-bridge inverter of AC motor

A technology of AC motors and inverters, which is applied in the direction of AC motor control, intermediate conversion to DC conversion equipment, conversion of AC power input to AC power output, etc., and can solve problems such as voltage increase and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

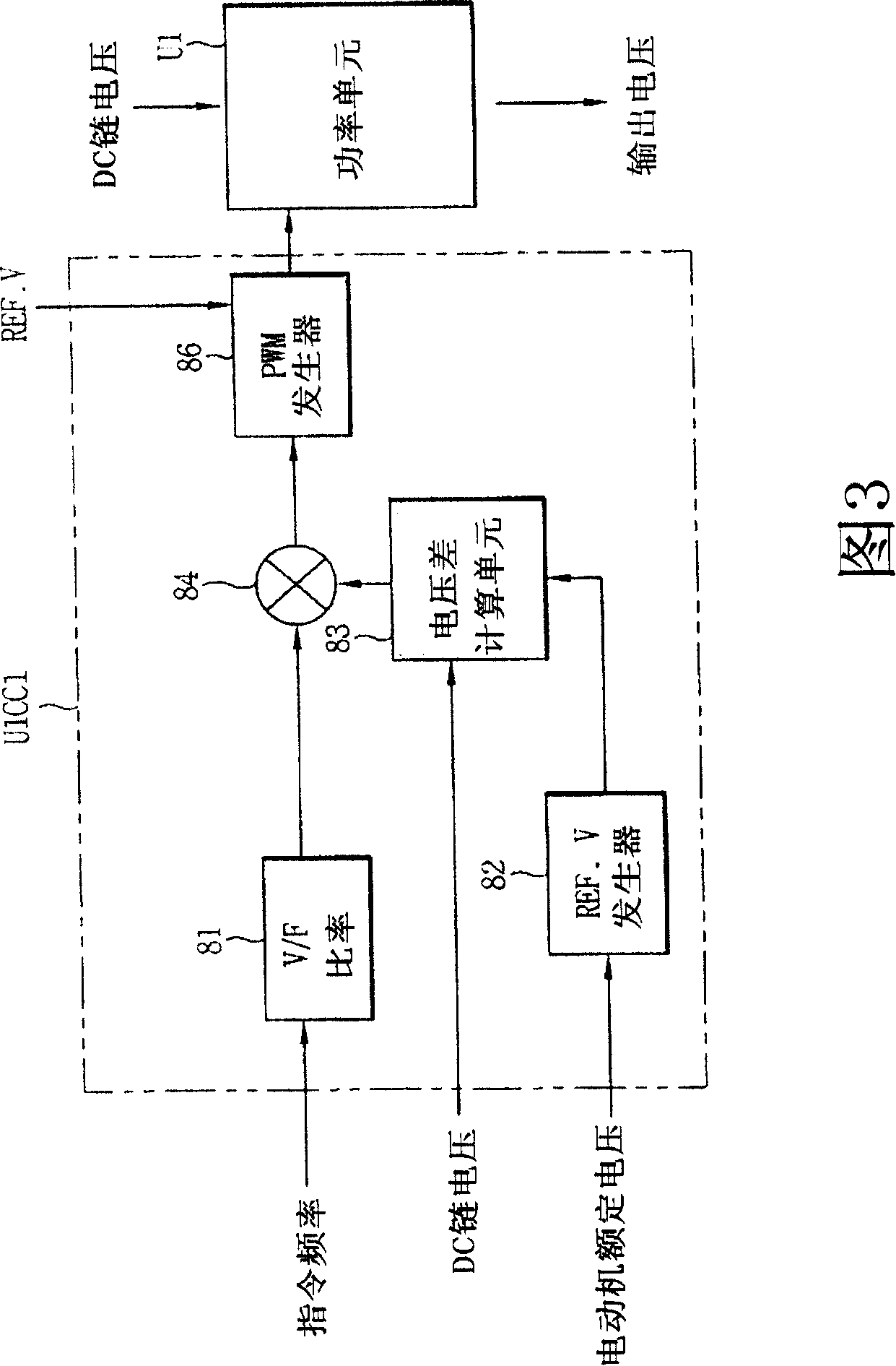

[0026] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

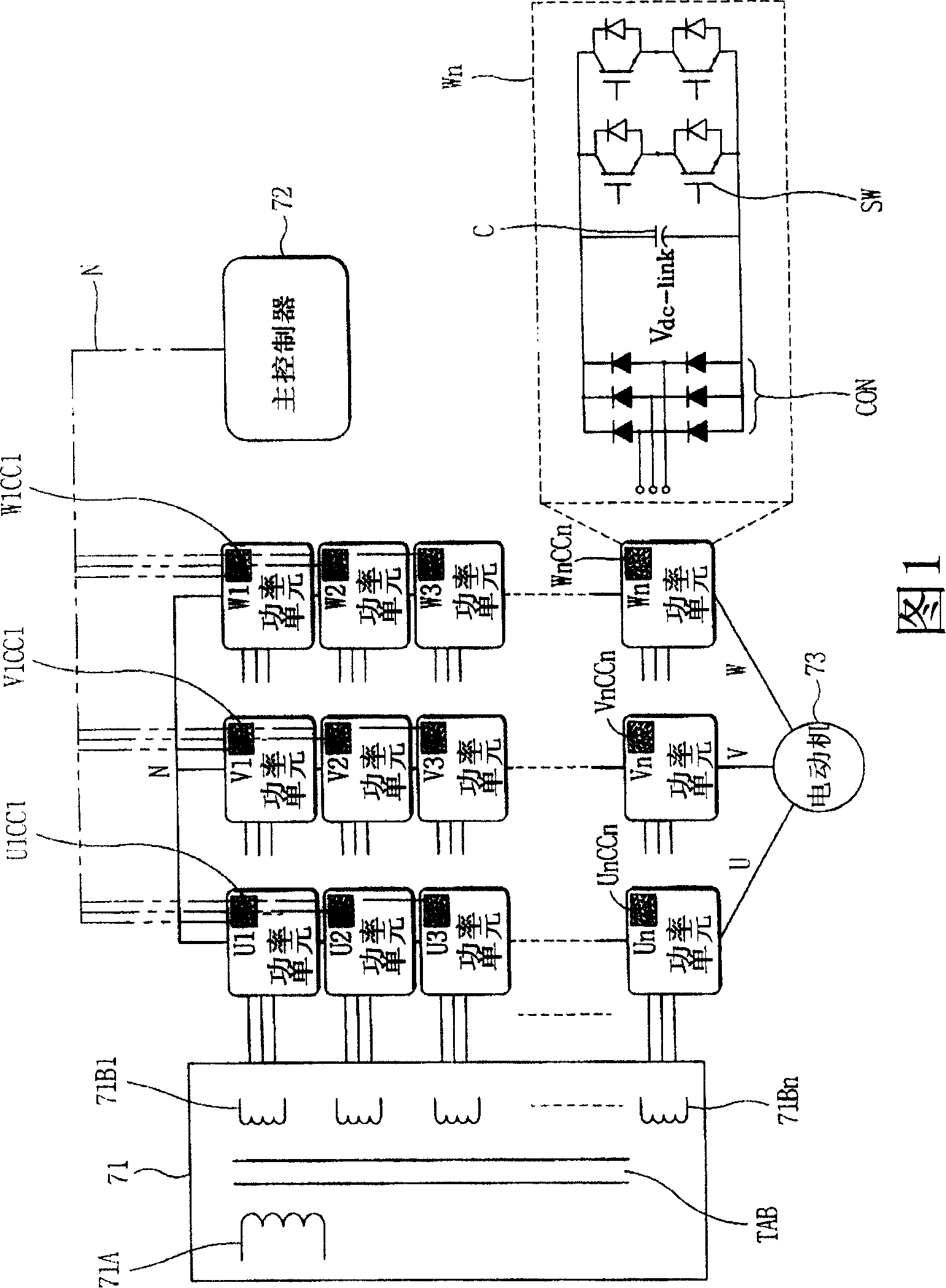

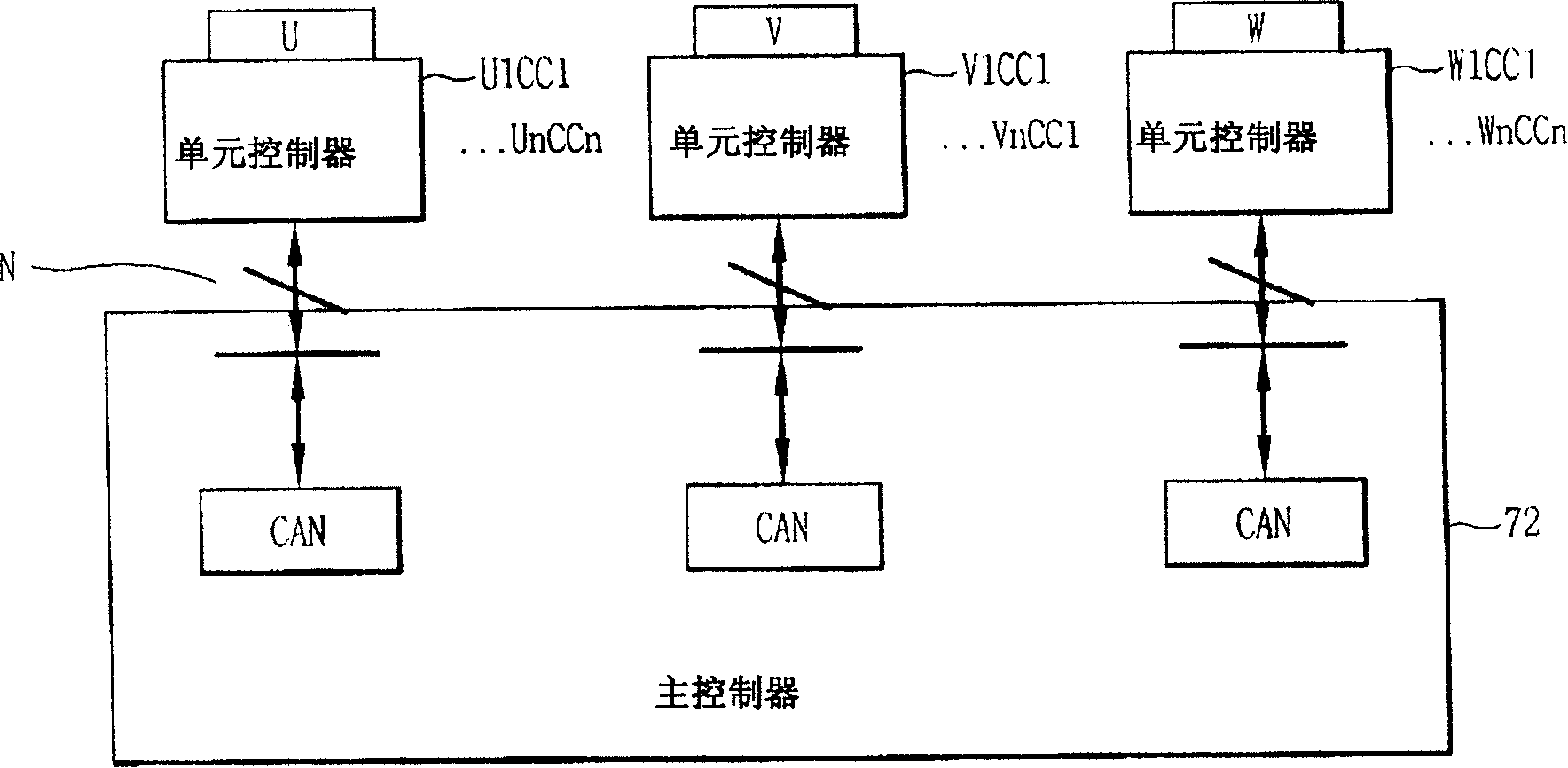

[0027] FIG. 1 is a block diagram showing the entire structure of an H-bridge inverter for an AC motor according to the present invention.

[0028] As shown in FIG. 1 , the H-bridge inverter for an AC motor according to the present invention includes a phase-shifting transformer 71 .

[0029] The phase shift transformer 71 includes a primary coil 71A and a plurality of secondary coils 71B1 to 71Bn. The primary coil 71A is formed of a three-phase delta coil receiving a three-phase AC power such as AC220V and a frequency of 60 Hz. The secondary coils 71B1˜71Bn convert, for example, the voltage of AC220V of the primary coil 71A to 24V and supply 24V to each of the power units U1˜Un, V1˜Vn, W1˜Wn, and are formed of triangular coils. TAB is a center tap located between the primary coil 71A and the secondary coils 71B1 to 71Bn....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com