Arrangement construction for nose plate of extensible-top automobiles

A technology for arranging structures and front floors, applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve the problem that the strength cannot meet the needs of retractable roof vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The layout structure of the front floor of the vehicle of the present invention is described below according to the illustrated embodiment:

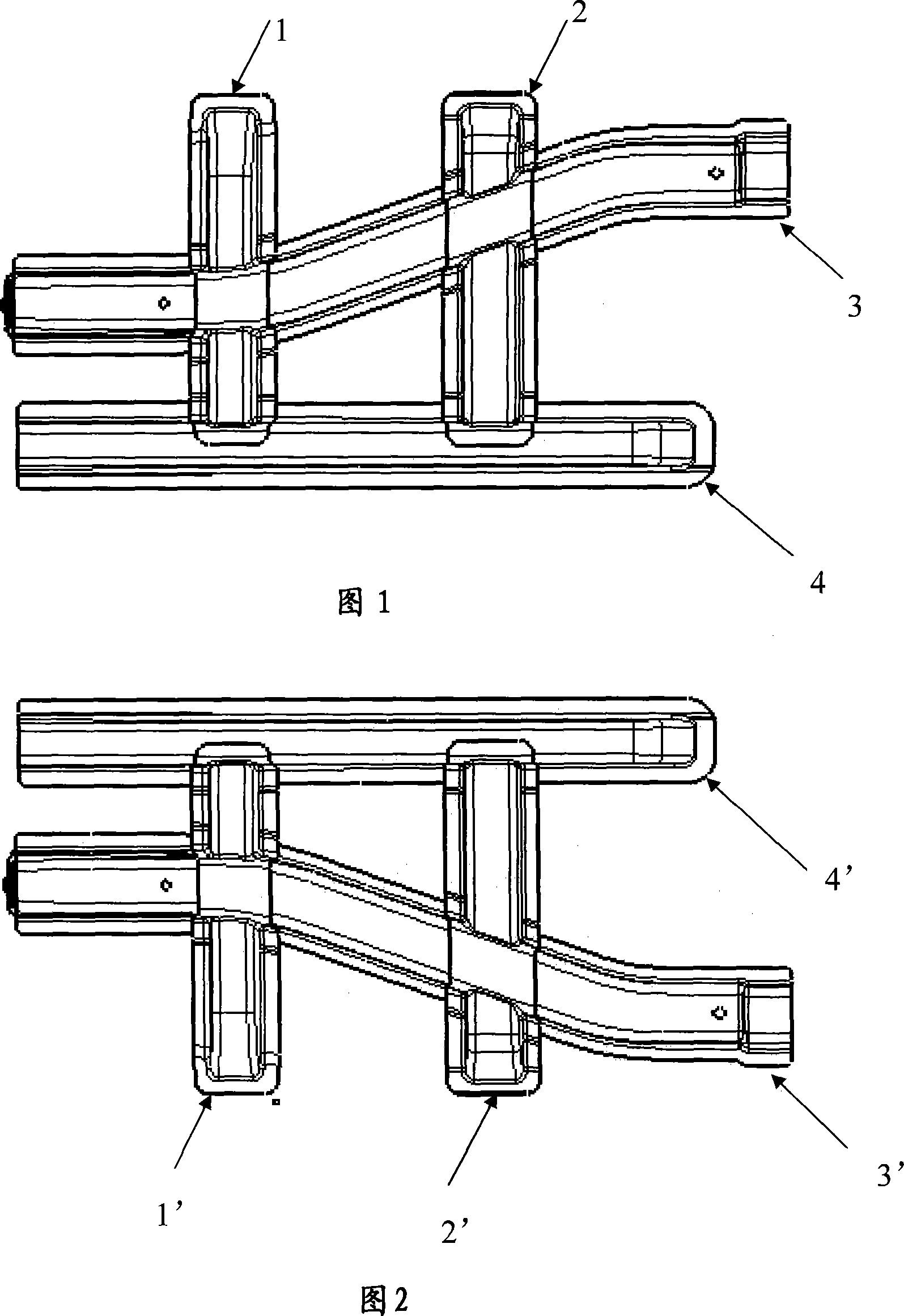

[0014] First, as shown in Figures 1 and 2, it is the front floor lower assembly of the present invention, the front floor longitudinal beams 3, 4 and the front floor lower beams 1, 2 are welded together to form the right side structure of the front floor lower assembly 8; The longitudinal beams 3', 4' of the front floor and the lower beams 1', 2' of the front floor symmetrical to the corresponding parts on the right side are welded together to form the left side structure of the lower part of the front floor.

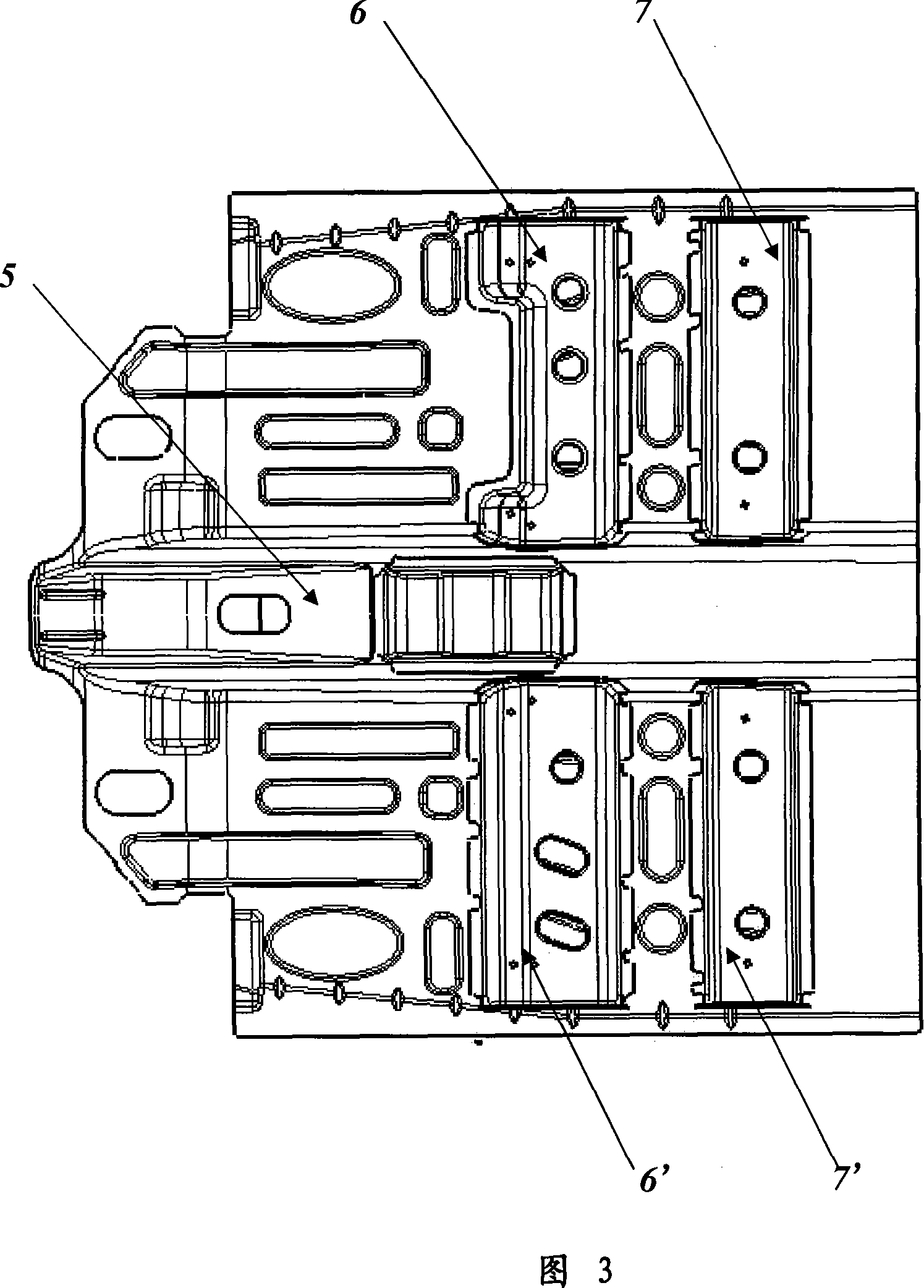

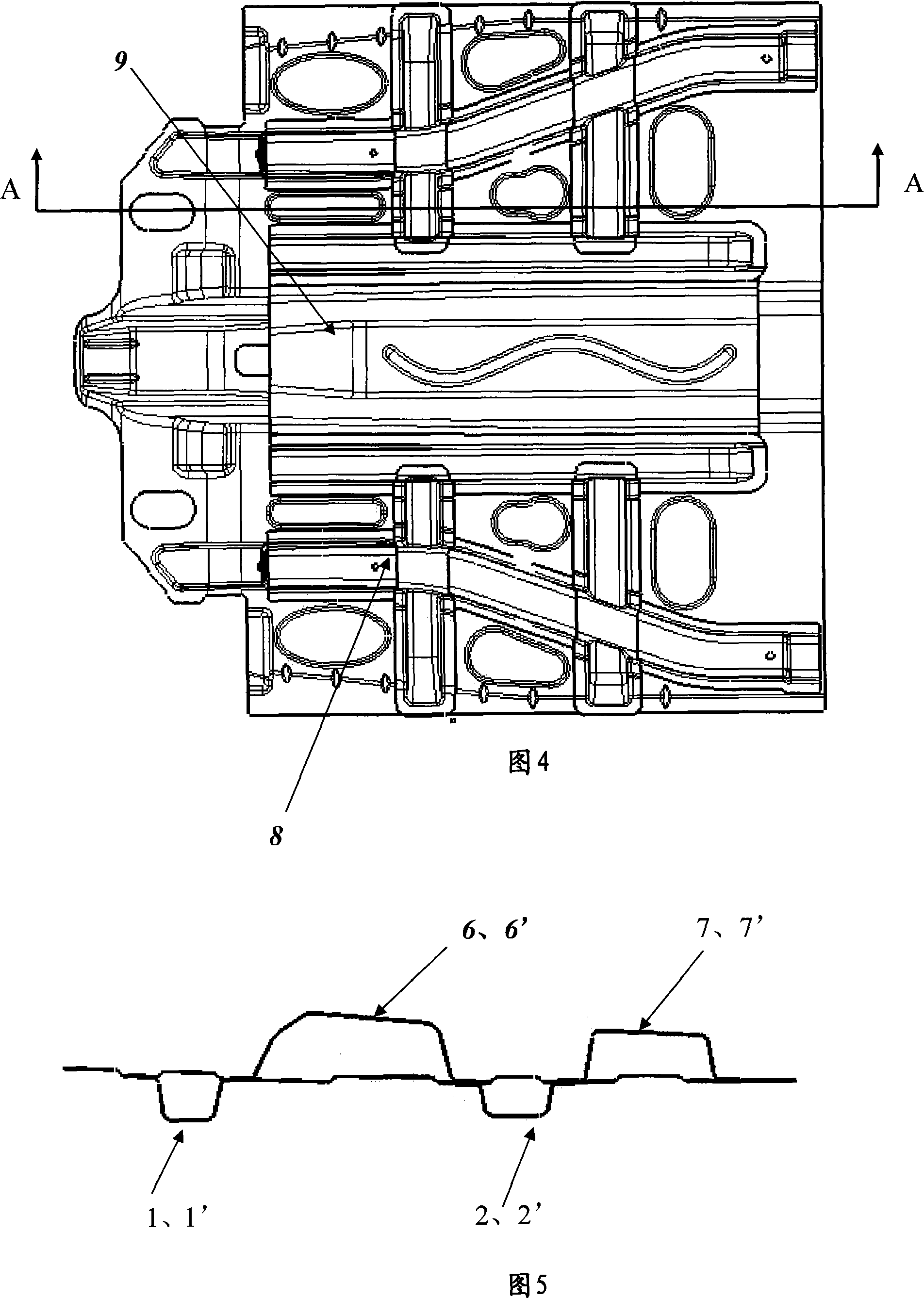

[0015] Then, as shown in Figure 3, the front floor body 5, the front and rear mounting beams 6, 7 of the right seat, the front and rear mounting beams 6', 7' of the left seat, and the middle channel reinforcement plate are welded together to form the front floor body assembly. into 9.

[0016] Finally, as shown in Figures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com