Temperature simple calibrating method suitable for reflection-type polarization-preserving fiber temperature sensor

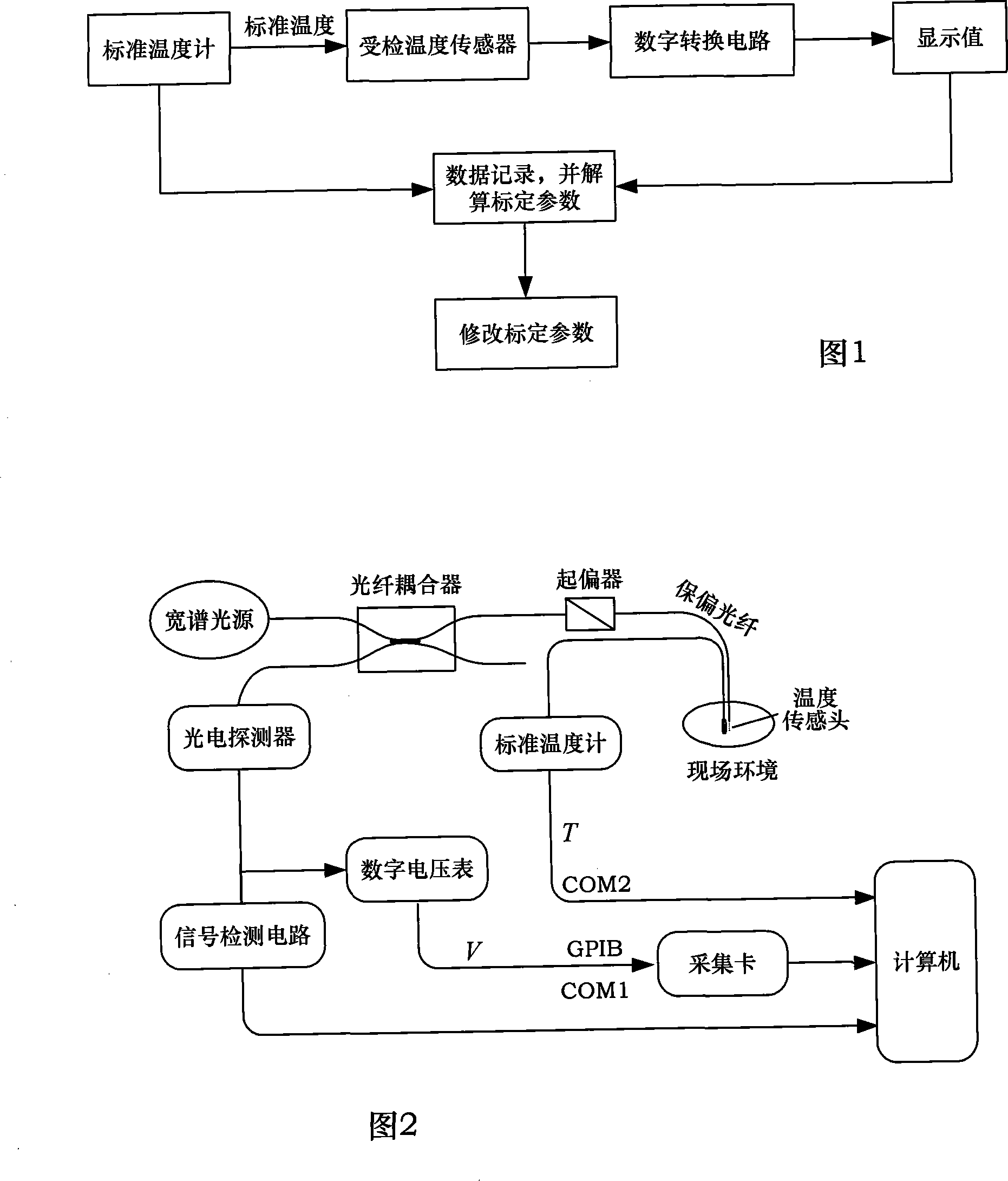

A temperature sensor and polarization-maintaining fiber technology, which is applied in the field of temperature calibration with simple operation, can solve the problems of complex processing process, cumbersome and time-consuming data acquisition, and inability to evaluate the calibration quality, and achieves the effect of satisfying performance requirements and excellent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

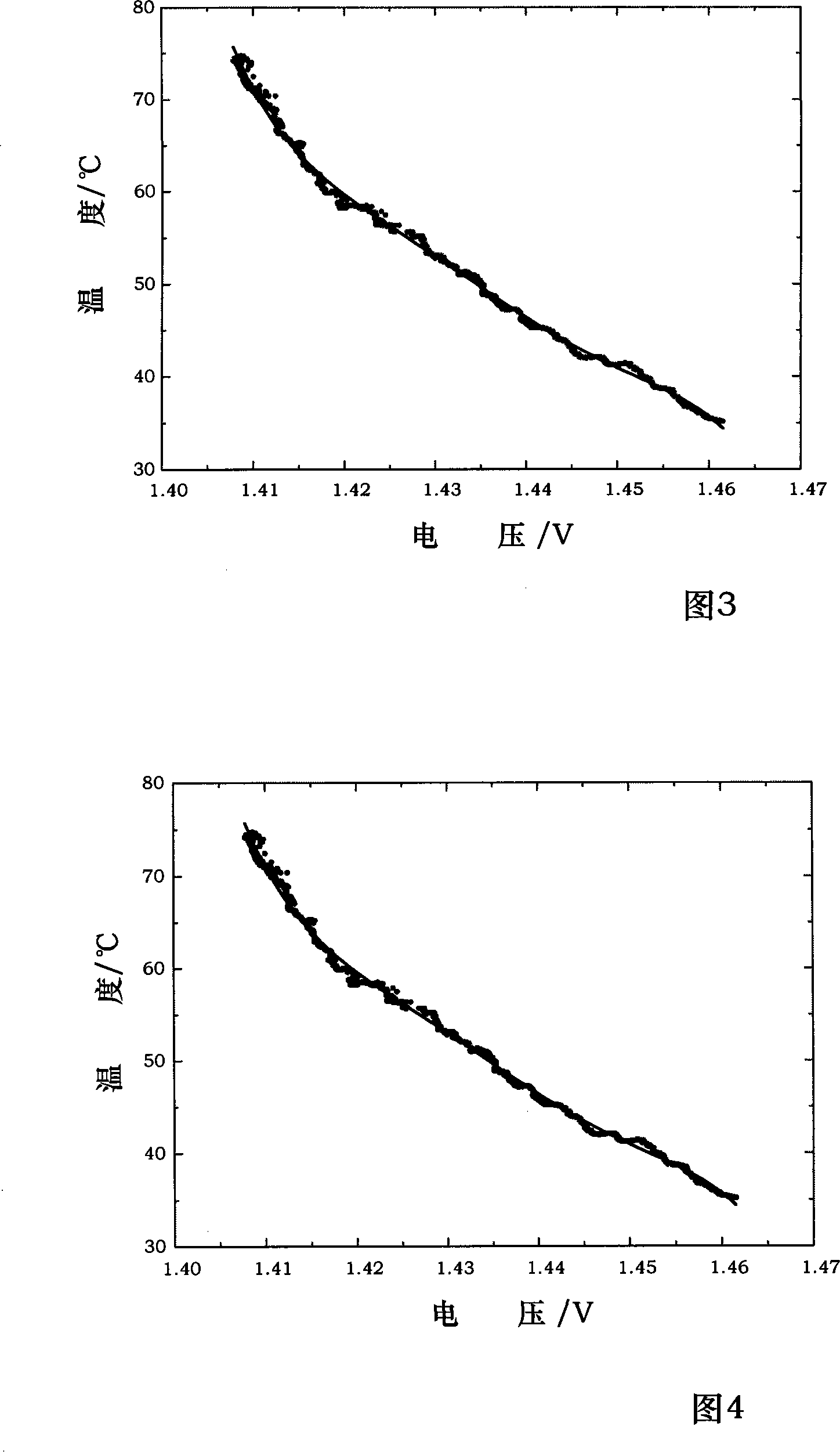

[0082] According to the connection of each device as shown in Figure 2, the microprocessor in the signal detection circuit selects the C8051F060 chip, the photodetector selects the PFTM911 InGaAs planar structure PIN-FET detector, and the standard thermometer selects the XMT-5 intelligent digital sensor with a platinum resistance The display control instrument, the digital voltmeter uses the 34970A voltmeter produced by agilent company, the acquisition card uses the NI company's GPIB card, and the computer uses the P4 1.6G processor.

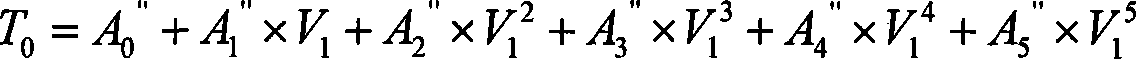

[0083] The sensing head of the temperature sensor and the sensing head of the standard thermometer are fixed together with insulating tape, and placed in a ceramic closed constant temperature electric furnace to heat the beaker. The temperature was raised from room temperature to 75°C, then lowered, and the experimental data were collected in real time. The collected temperature T 0 and the voltage value V 0 Draw a T-V curve, and use Origin so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com