Oxygen-absorbing pouch container

A technology of oxygen absorption and oxygen absorber, which is applied in the direction of flexible containers, containers, and anti-rot containers, etc. It can solve the problems of reduced rigidity of the sealing part, and achieve the effects of stable oxygen absorption performance, good formability, and high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

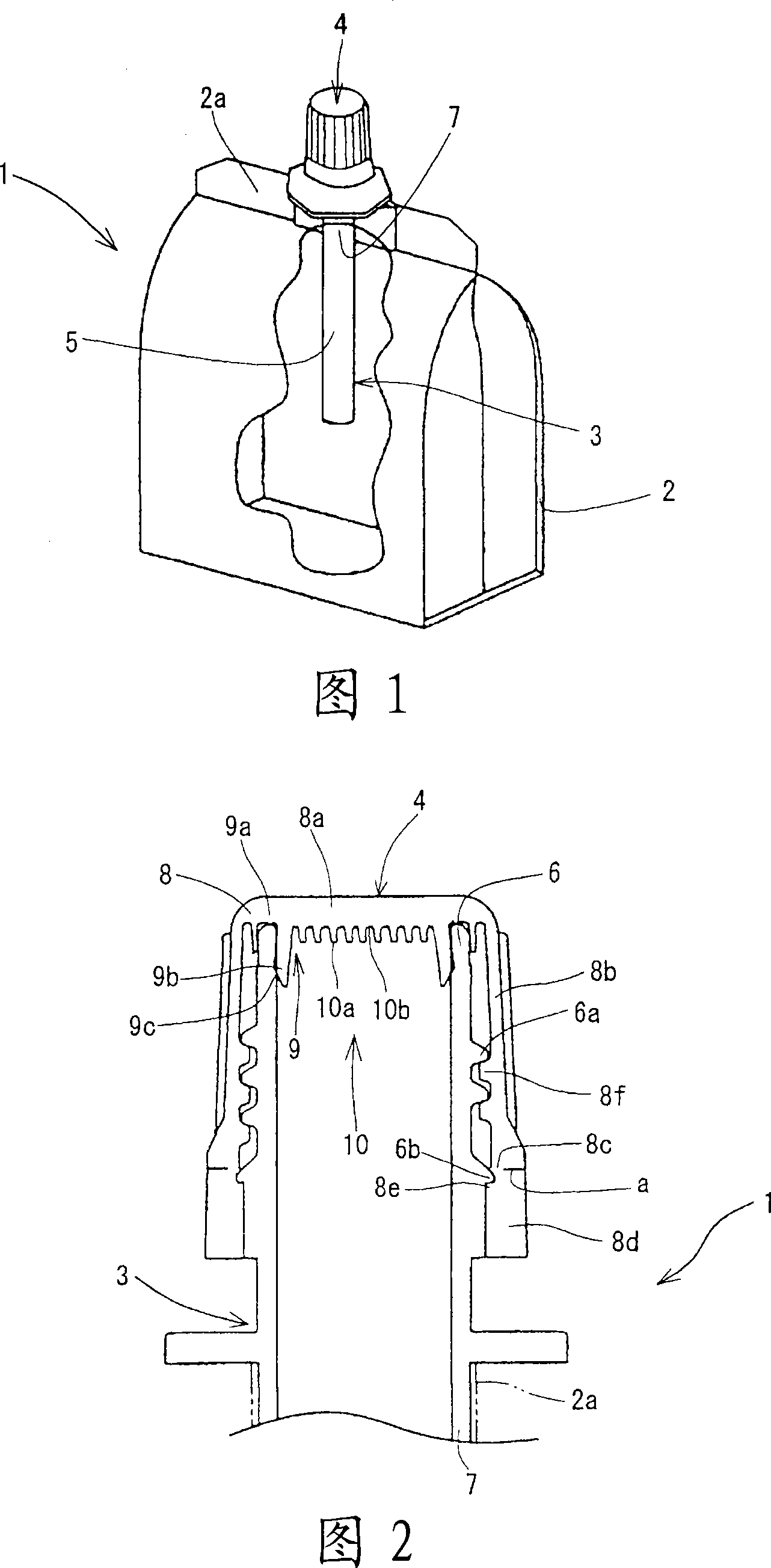

[0037]One embodiment of the present invention is shown in FIGS. 1 and 2. FIG. 1 is a partially perspective perspective view schematically showing the composition of an oxygen-absorbing bag container (hereinafter referred to as a bag container) 1 according to one embodiment of the present invention; FIG. 2 It is a vertical cross-sectional view schematically showing the configuration of main parts of the bag container 1 .

[0038] As shown in Figure 1, the bag container 1 comprises a bag-shaped container body 2, a spout 3 mounted on the container body 2, a spout 6 detachably mounted on the spout 3 (see Figure 2 ) cover 4.

[0039] The above-mentioned injection pipe 3 has a tubular (cylindrical in this embodiment) conduit portion 5 inserted into the container body 2, and a cylindrical (in this embodiment) conduit portion 5 exposed to the outside of the container body 2. The center is cylindrical) spout part 6 (refer to Fig. 2) and fixing part 7, and described spout part 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com