Power transmission device, and display device and display panel pedestal that have the power transmission device

A technology of power transmission device and display panel, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of different torque, difference in the quality of rotating objects, adjusting the reduction ratio of the reducer, etc., to eliminate the backlash Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

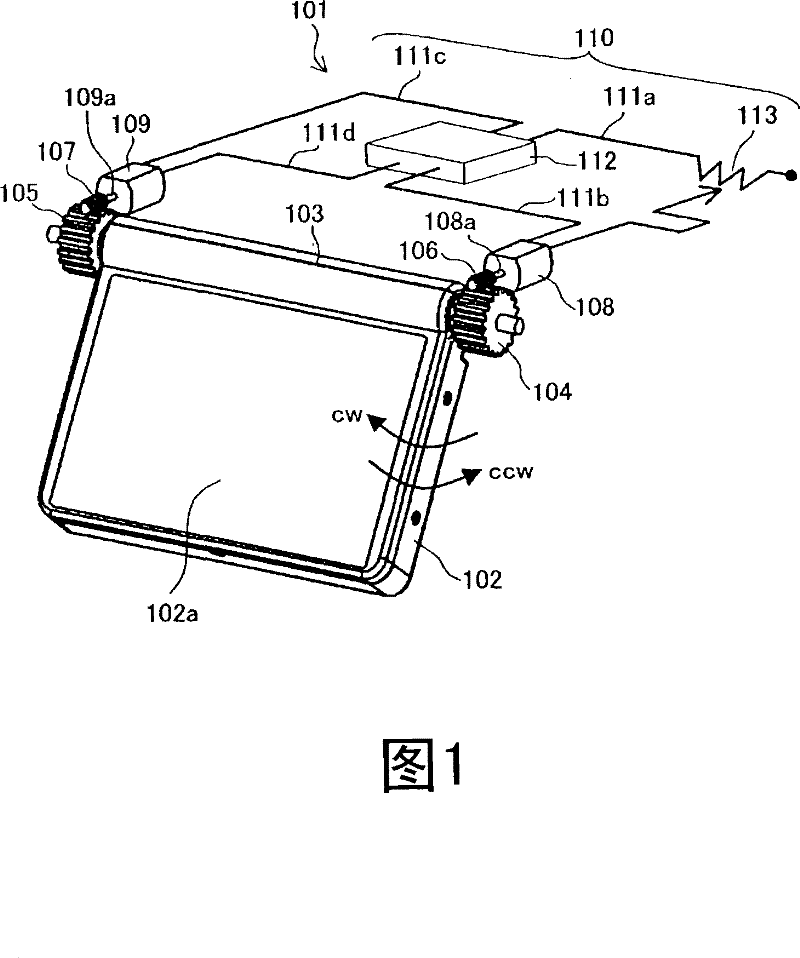

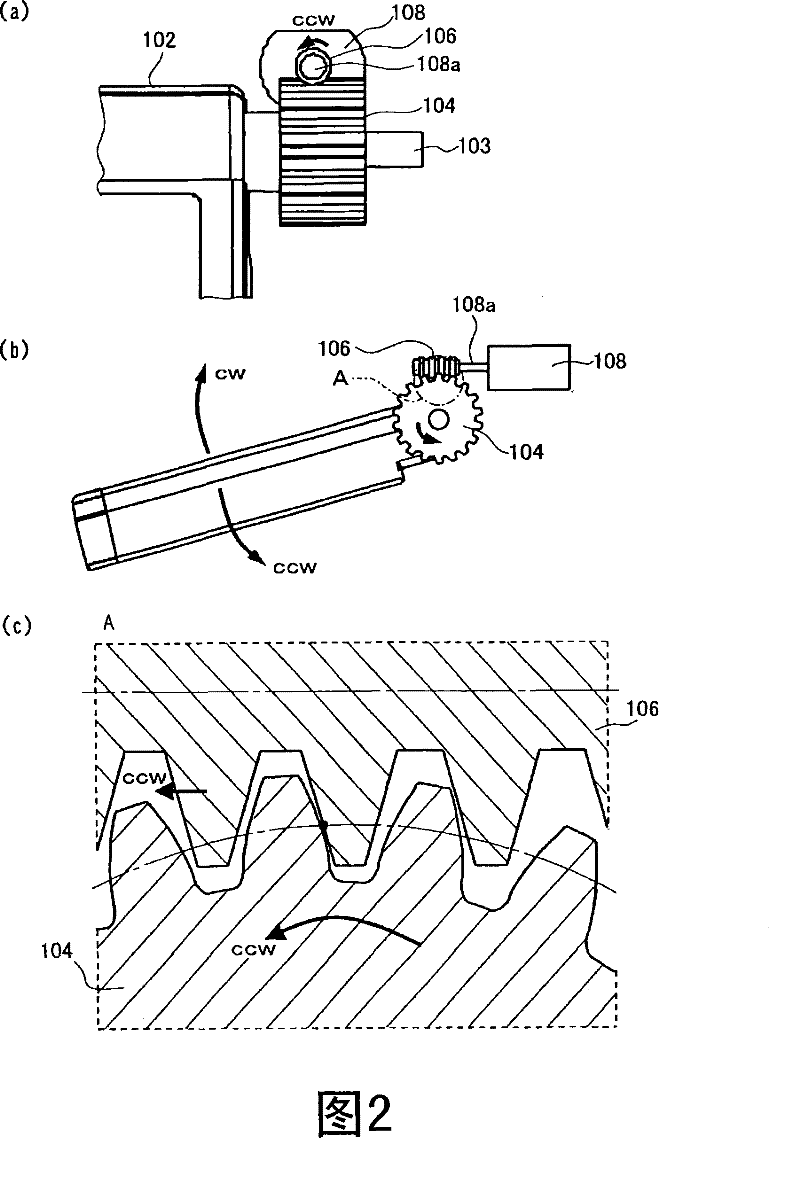

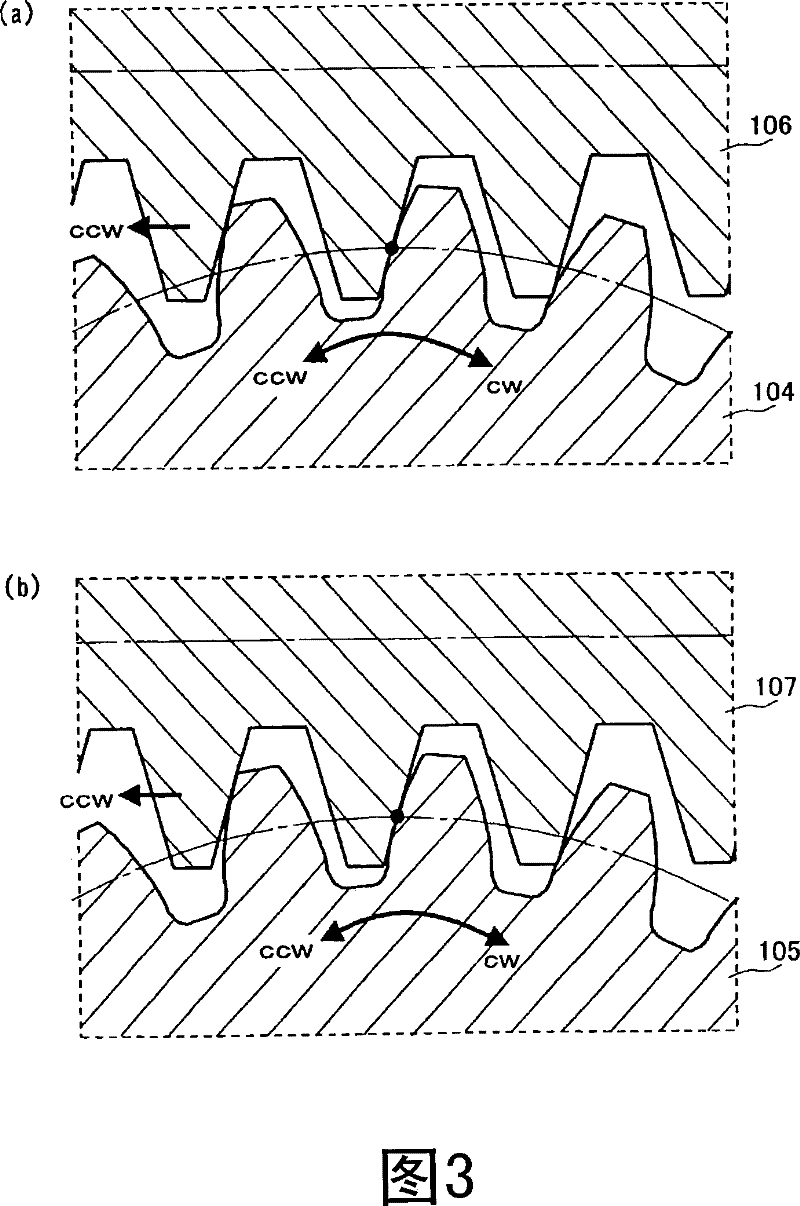

[0077] First, the configuration of a power transmission device and a display device using the same in Embodiment 1 of the present invention will be described with reference to FIGS. 1 and 2 . FIG. 1 is a perspective view showing the configuration of a power transmission device and a display device in Embodiment 1 of the present invention. Fig. 2 is a diagram showing the meshing state of the transmission gear and the output gear in the power transmission device shown in Fig. 1, Fig. 2 (a) is a front view viewed from a direction perpendicular to the output shaft of the power transmission device, Fig. 2 (b ) is a side view viewed from the axial direction of the output shaft of the power transmission device, and FIG. 2( c ) is a cross-sectional view showing a section of part A shown in FIG. 2( b ).

[0078] As shown in FIG. 1 , the display device in the first embodiment includes the power transmission device 101 and the display panel 102 in the first embodiment. In addition, the ...

Embodiment approach 2

[0119] Next, the structure of a power transmission device according to Embodiment 2 of the present invention and a display device using the same will be described with reference to FIGS. 7 and 8 . 7 is a perspective view showing a schematic configuration of a power transmission device and a display device according to Embodiment 2 of the present invention. FIG. 8 is an enlarged view of a part of the power transmission device shown in FIG. 7, FIG. 8(a) is a diagram showing the installation portion of the torsion coil spring 605, and FIG. 8(b) is a diagram showing the installation portion of the torsion coil spring 604. picture.

[0120] Among the constituent elements shown in FIG. 7 , the constituent elements that are the same as the constituent elements used in Embodiment 1 and shown in the drawings are given the same reference numerals as those used in Embodiment 1. In FIG. Furthermore, in the following description, description of the same constituent elements as those shown...

Embodiment approach 3

[0151] Next, configurations of a power transmission device according to Embodiment 3 of the present invention and a display device using the same will be described with reference to FIGS. 12 to 15 . 12 is a perspective view showing a schematic configuration of a power transmission device and a display device in Embodiment 3 of the present invention. 13 is an enlarged perspective view of a part of the power transmission device shown in FIG. 12 , FIG.

[0152] Fig. 14 is a diagram showing the positional relationship between the blades provided on the output shaft shown in Fig. 12 and the blades provided on the rotary switch. 15( a ) is a circuit diagram showing a control circuit of the power transmission device shown in FIG. 12 , and FIG. 15( b ) is a diagram showing switching combinations of the rotary switches shown in FIG. 15( a ).

[0153] Components shown in FIGS. 12 to 17 that are the same as components used in Embodiments 1 and 2 and shown in the drawings are assigned th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com