Method for preparing multi-channel type hydrogen permeation palladium-based composite membrane

A multi-channel, composite membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of difficult coating, toxic hydrazine vapor emission, high temperature, etc., to achieve uniform growth, reduce Emission, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

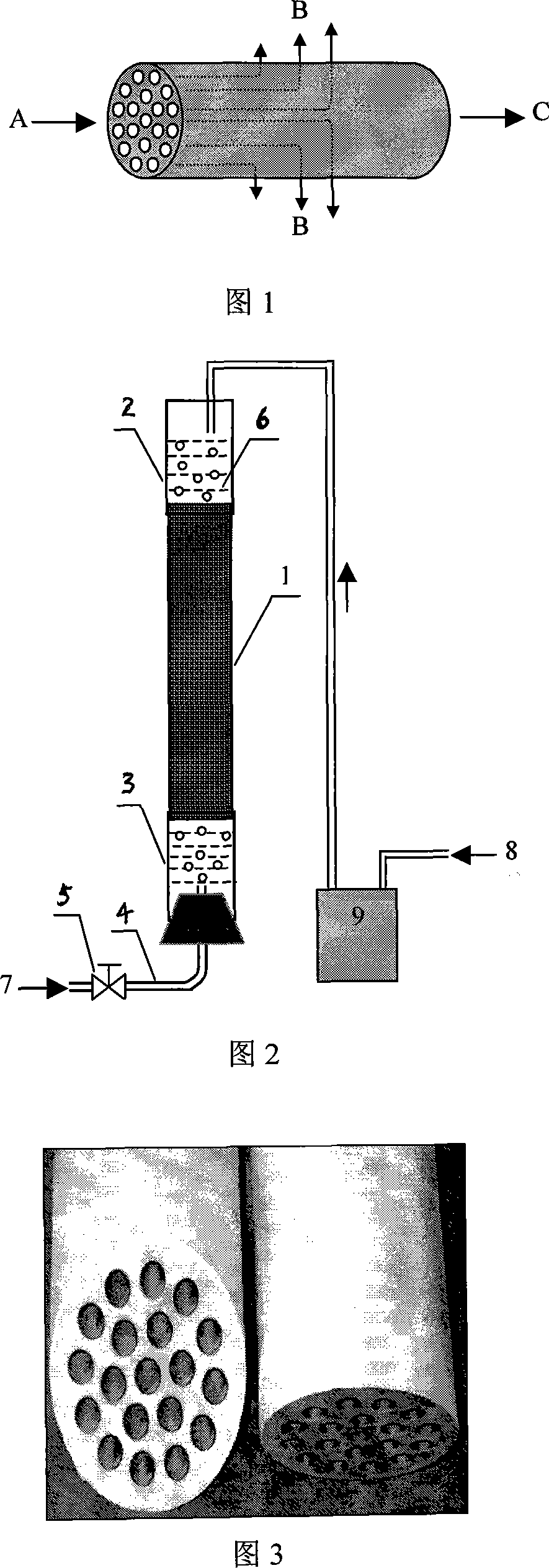

[0033] (1). The selected porous ceramic carrier has an average pore diameter of 0.2 μm, 19 channels, an outer diameter of 30 mm, and a length of 5 cm. The channels are circular and the channel diameter is 4 mm.

[0034] (2). Wash the multi-channel ceramic carrier with a commercially available detergent solution, and then rinse with water.

[0035] (3). Using conventional SnCl 2 / PdCl 2 The inner surface of the channel is activated by the method, in which the sensitizing solution contains SnCl 2 2H 2 O5g / L, concentrated hydrochloric acid 1ml / L; activation solution contains PdCl 2 0.2g / L, concentrated hydrochloric acid 1ml / L. Wrap the outer surface of the carrier with polytetrafluoroethylene tape, first dip in the sensitizing solution and rinse with water, then dip in the activation solution and rinse with water. Sensitization——After 5 times of activation treatment, disassemble the PTFE tape and soak it in water for 1 hour.

[0036] (4). As shown in Figure 2, the electrol...

Embodiment 2

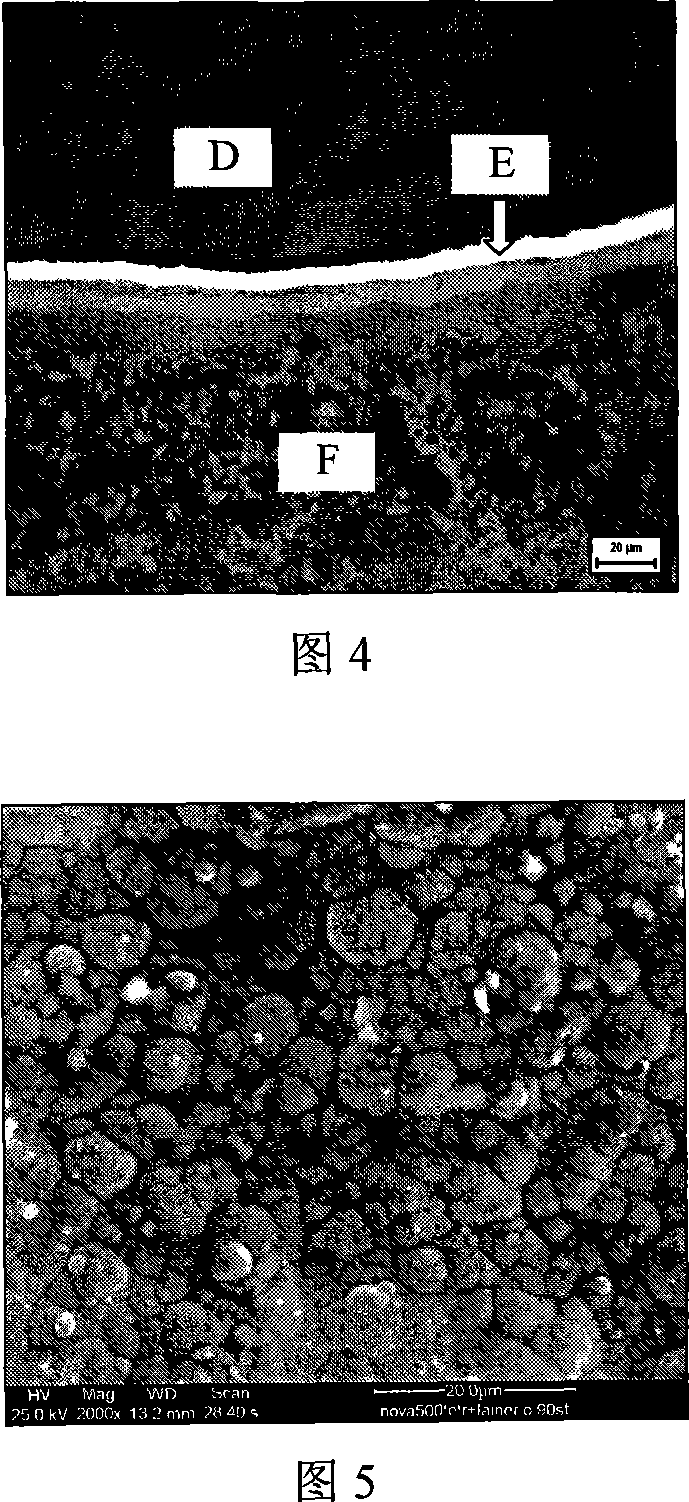

[0040] Operation mode is the same as embodiment one, but the length of the porous ceramic carrier selected is 11cm, and the composition of plating solution is: Pd(C 2 h 3 o 2 ) 2 3g / L, concentrated ammonia water 150ml / L, K 2 EDTA 50g / L. The total amount of plating solution used is 530ml, and the thickness of the palladium film produced is about 5 μm.

Embodiment 3

[0042] Same as Example 1, but the length of the porous ceramic carrier selected is 50 cm, the electroless plating reaction temperature is 35 ° C, and the reducing agent is 0.2 mol / L N 2 h 4 solution, the gas flow rate is 70ml / min, the adding rate of reducing agent is 0.1ml / min, the bubbling gas at the bottom is argon, the total usage of plating solution is 3000ml, and the palladium film thickness is about 6.2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap