Silicon rubber oxygen-enriched film doped silicon dioxide and preparation method thereof

A silicone rubber oxygen-rich membrane, silica technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as unfavorable industrial applications, aging resistance and poor acid and alkali resistance, and achieve film formation. The effect of improving performance and oxygen enrichment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

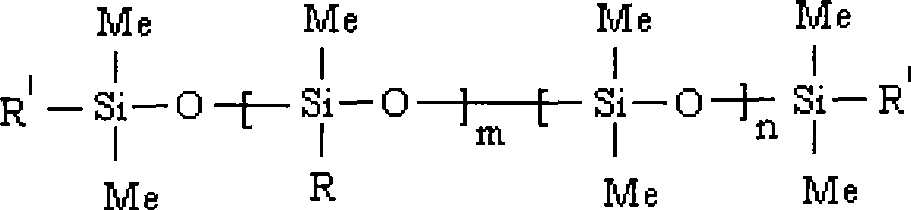

[0038] The preparation method of the silicone rubber oxygen-enriched membrane doped with silicon dioxide comprises: coating a coating on the polymer base film to form a composite membrane; the coating includes a vinyl silicone rubber and a silicon dioxide blend, or blends of hydroxyl-containing silicone rubber and silica;

[0039] When vinyl silicone rubber and silicon dioxide are blended, polysiloxane containing silicon hydrogen groups is used as a crosslinking agent, wherein the vinyl group of vinyl silicone rubber and the silicon hydrogen group of polysilane containing silicon hydrogen groups The molar ratio is 1:0.6-1.6; firstly disperse the silicon dioxide in the solvent evenly, and then add it to the uniformly mixed vinyl silicone rubber according to the proportion that the content of silicon dioxide in the solution is 2-50%. and cross-linking agent solution, stir at room temperature for 1-10 hours, add metal compound catalyst, which contains 1g of vinyl silicone rubber,...

Embodiment 1

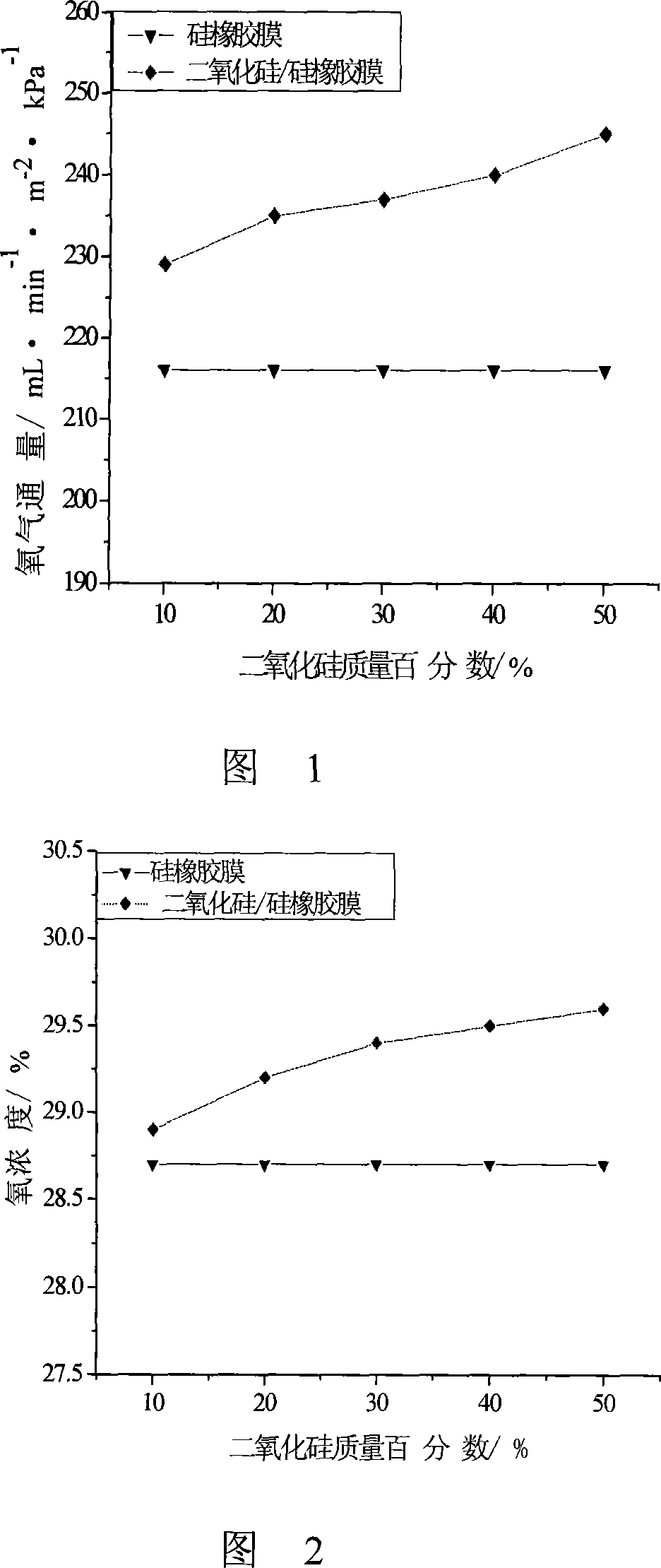

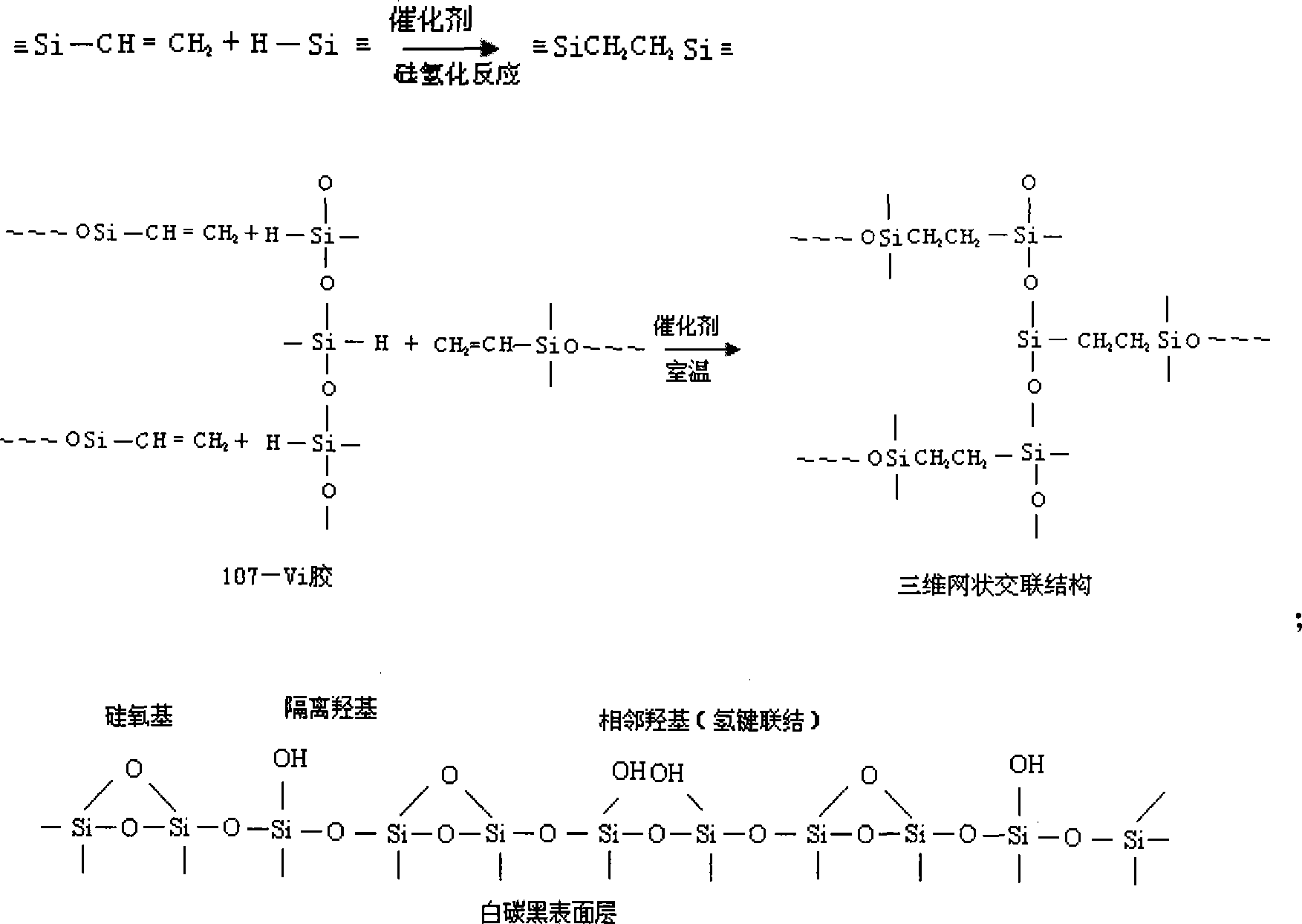

[0055] Example 1: Add 10 parts of vinyl silicone rubber and 1 part of polysiloxane containing silicon hydrogen groups to 200 parts of n-pentane solvent and stir evenly; add 4 parts of fumed silica to 50 parts of n-pentane solvent Stir until evenly dispersed, add it to the solution of vinyl silicone rubber and polysiloxane containing silicon hydrogen group and stir for 1 hour, then add 0.02mL chloroplatinic acid composite catalyst and stir for 1 hour, after removing the surface foam, apply Spread it on the base film and cure it at 80°C for 1 hour to obtain an oxygen-enriched film. Under 0.075MPa vacuum degree and 25°C, with air as the gas source, the oxygen concentration in the test enriched oxygen is 30.5%, and the flux of enriched oxygen is 245mL / (min·m 2 · KPa).

Embodiment 2

[0056] Example 2: Add 10 parts of vinyl silicone rubber and 1 part of polysiloxane containing silicon hydrogen groups into 200 parts of n-pentane solvent and stir evenly; add 4 parts of fumed silica into 50 parts of n-pentane solvent Stir until evenly dispersed, add it to the solution of vinyl silicone rubber and polysiloxane containing silicon hydrogen groups and stir for 1 hour, add 0.03mL chloroplatinic acid catalyst and stir for 1 hour, remove the surface foam, and apply Spread it on the base film and cure it at 80°C for 1 hour to obtain an oxygen-enriched film. Under a vacuum of 0.075MPa and 25°C, with air as the gas source, the oxygen concentration in the test enriched oxygen is 30.5%, and the flux of the enriched oxygen is 243mL / (min·m 2 · KPa).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap