Method for manufacturing steel strip combined oil-control ring wiper blade ring and backing ring material flat steel strip molding

A technology of combining oil and flat steel strips, applied in metal rolling, wire drawing dies, etc., can solve the problems of poor size and shape accuracy, affecting product quality, and increasing the workload of subsequent forming machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

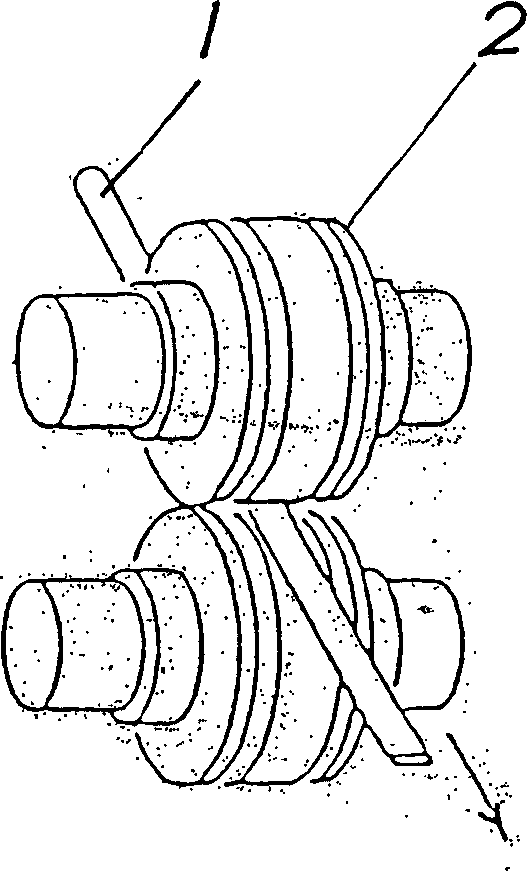

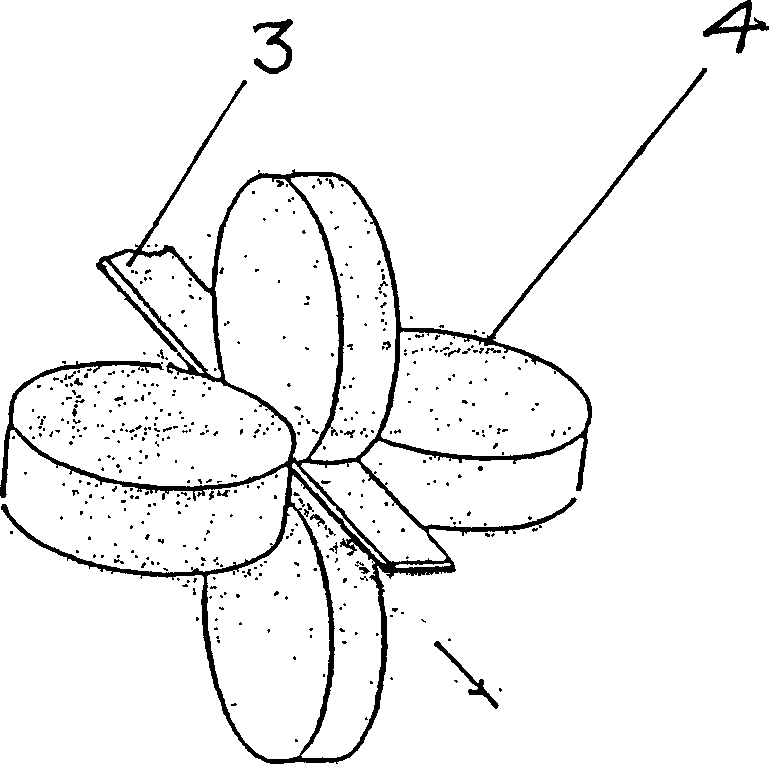

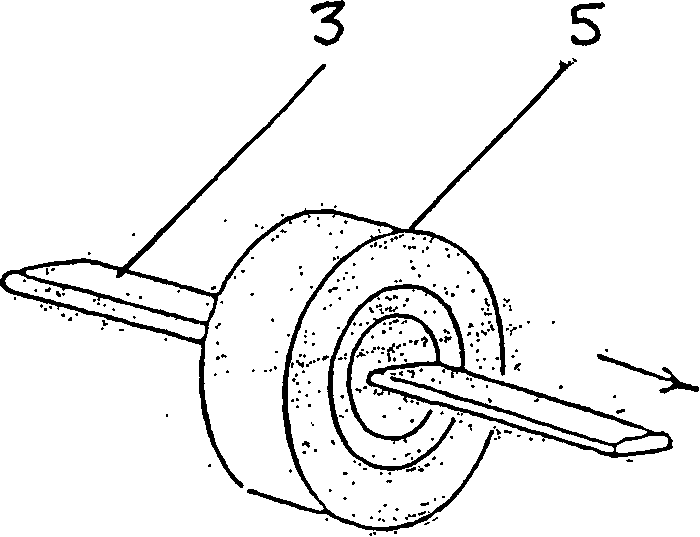

[0010] It can be known from the figure that the manufacturing method of forming the flat steel strip of this steel strip combination oil ring scraper ring and lining ring material is: drawing the qualified wire rod into a round steel wire (1) with a cross-sectional area close to the finished flat steel strip, This round steel wire (1) is rolled by a rolling mill (2) to achieve the effect of initial rolling and flattening (see details). figure 1 shown), the flat steel strip (3) after initial rolling reaches the required cross-sectional shape and size after being rolled by the roll die (4) (see figure 2 shown), then the flat steel strip (3) drawn by the roller drawing die (4) reaches the required cross-sectional shape and size after being drawn by the flat wire drawing die (5). In addition, the cross-sectional area of this round steel wire (1) should be controlled within the scope of 1: 1.2 with the ratio of the cross-sectional area of the flat steel strip (3) rolled by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com